Wheat Flour Mill and Maize Mill

- Payment Type:

- L/C, T/T, Paypal, Money Gram, Western Union, cash

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, Paypal, Money Gram, Western Union, cash |

Product Description

Product Description

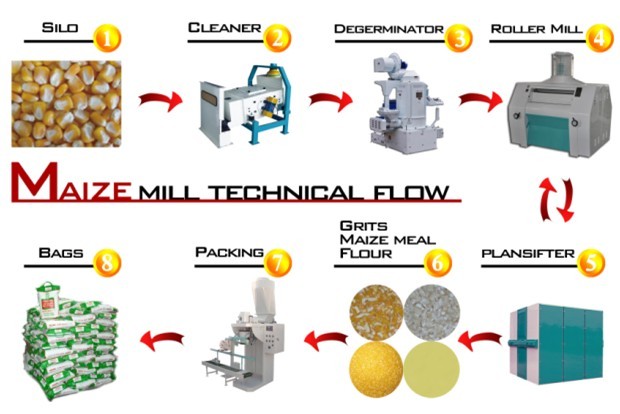

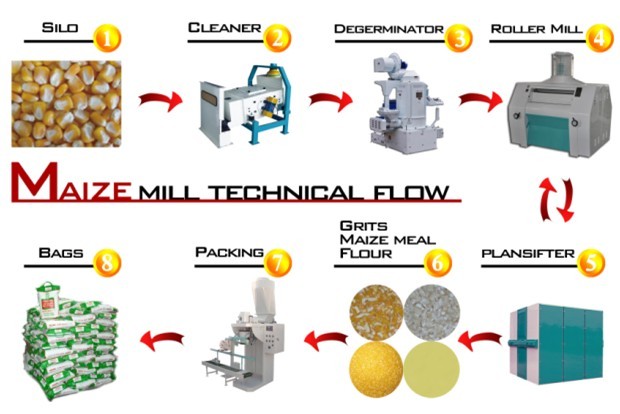

Vertical Frictional maize degerminator, which is integrated in multiple most-advanced technologies, is applicable for taking the germ and bran out of the maize, at the same time polishing the maize/maize gritz, get pure white /yellow maize meal, maize grits, maize samp, and is characteristic of high volume of production, compact structure and convenient maintenance, thus making it an ideal equipment for maize processing in the modern age

we suply turnkey project of 5T-500T/24H wheat flour miling machines and 5T-300T/24H maize flour milling machines. we have our office in South Africa, Zambia, Congo and Brazil

We have export to many countries, like America (100T/24h), Venezuela (50T/24h),

Brazil (60T/24h) Ethiopia (500T/24h), Zimbabwe(120T/24h) , Benin(150T/24H) etc.

1. Clean system

Includes beating, screening, destoner, magnetic separator and dampening. Different capacity machine line has different number of beat, screen and stoner.

Advanced equipment: Degerminator:

It is designed to "scrub" the bran skin from the maize kernel and to dislodge the germ from its cavity, with the minimum reduction in size of the broken fragments.

2. Flour milling system

Include different number of mill and sifter to mill the wheat and separate the flour and bran.

(1) Mill: mill the wheat to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to ensure flour quality.

3. Packing system

The packing system can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

we suply turnkey project of 5T-500T/24H wheat flour miling machines and 5T-300T/24H maize flour milling machines. we have our office in South Africa, Zambia, Congo and Brazil

We have export to many countries, like America (100T/24h), Venezuela (50T/24h),

Brazil (60T/24h) Ethiopia (500T/24h), Zimbabwe(120T/24h) , Benin(150T/24H) etc.

1. Clean system

Includes beating, screening, destoner, magnetic separator and dampening. Different capacity machine line has different number of beat, screen and stoner.

Advanced equipment: Degerminator:

It is designed to "scrub" the bran skin from the maize kernel and to dislodge the germ from its cavity, with the minimum reduction in size of the broken fragments.

2. Flour milling system

Include different number of mill and sifter to mill the wheat and separate the flour and bran.

(1) Mill: mill the wheat to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to ensure flour quality.

3. Packing system

The packing system can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

Related Keywords

Related Keywords