Rubber Liner Slurry Pump with Motor

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, SHANGHAI, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Productivity: | 300sets/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,SHANGHAI,Ningbo |

Rubber Lined Slurry Pump:

1. Slurry pumps are cantilevered, horizontal, centrifugal pumps. They are designed for the handing highly abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial department ect.

2.The pumps of this type also may be installed in multistage series. The pump of this type also may be installed in multistage series.

3. The frame plates for pumps have replaceable wear-resistant metal liner or rubber liners. The impellers are made of wear-resistant metal or rubber. The frame plate liner and impeller for BHH pump are adoptable of wear-resistant metal only.

4. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

5. There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, frequency conversion drive devices for the slurry pump.

Drive types:

V belt drive,

gear reducer drive,

coupling drive,

frequency conversion drive devices

Advantage:

Wide performance,

good NPSH and high efficiency.

The pump of this type may be installed in multistage series to meet the delivery for long distance

Application:

a. Slurry pump is widely used for transporting slurries with high ablation or high density.

b. Widely used for mining.

c. Widely used for metallurgy.

d. Widely used for building materials.

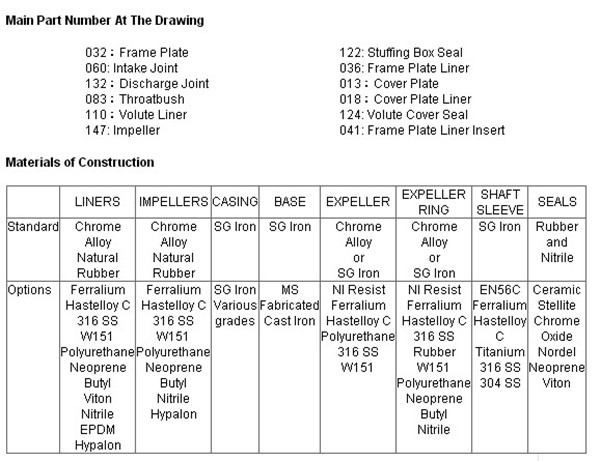

Rubber Lined Slurry Pump Performance Table:

|

Pump Model

|

Allowable Max. Power(kw)

|

Clear Water Performance

|

|

|||||

|

capacity Q

|

Head H(m)

|

speed n(r/min)

|

Max.eff. η%

|

NPSH (m)

|

Impeller Dia(mm)

|

|||

|

m3/h

|

l/s

|

|||||||

|

1.5/1B-BHR

|

15

|

10.8-25.2

|

3-7

|

7-52

|

1400-3400

|

35

|

|

|

|

2/1.5B-BHR

|

15

|

25.2-54

|

7-15

|

5.5-41

|

1000-2600

|

50

|

2.5-5.5

|

178

|

|

3/2C-BHR

|

30

|

36-75.4

|

10-21

|

13-39

|

1300-2100

|

|

2-4

|

213

|

|

4/3C-BHR

|

30

|

79.2-180

|

22-50

|

5-34.5

|

800-1800

|

59

|

3-5

|

245

|

|

4/3D-BHR

|

60

|

|||||||

|

6/4D-BHR

|

60

|

144-324

|

40-90

|

12-45

|

800-1350

|

65

|

3-5

|

365

|

|

6/4E-BHR

|

120

|

|||||||

|

8/6E-BHR

|

120

|

324-720

|

90-200

|

7-49

|

400-1000

|

65

|

5-10

|

510

|

|

8/6R-BHR

|

300

|

|||||||

|

10/8ST-BHR

|

560

|

540-1188

|

150-330

|

12-50

|

400-750

|

75

|

4-12

|

|

|

12/10ST-BHR

|

560

|

720-1620

|

200-450

|

7-45

|

300-650

|

80

|

2.5-7.5

|

|

|

14/12ST-BHR

|

560

|

1152-2520

|

320-700

|

13-14

|

300-500

|

79

|

3-8

|

|

|

16/14TU-BHR

|

1200

|

1368-3060

|

380-850

|

11-63

|

250-550

|

79

|

4-10

|

1067

|

* Dimensionally Interchangeable :

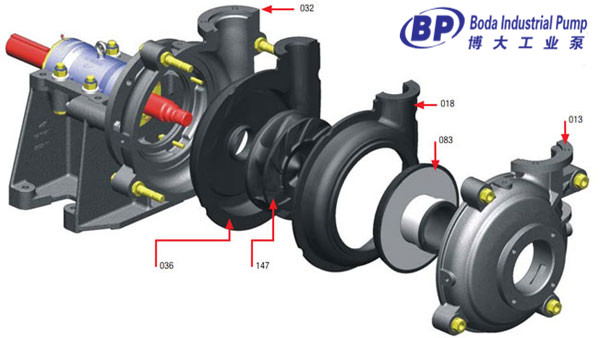

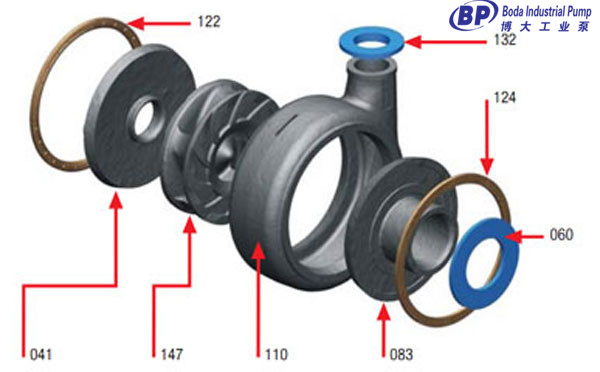

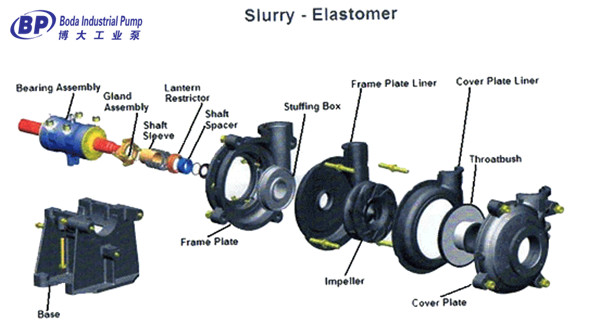

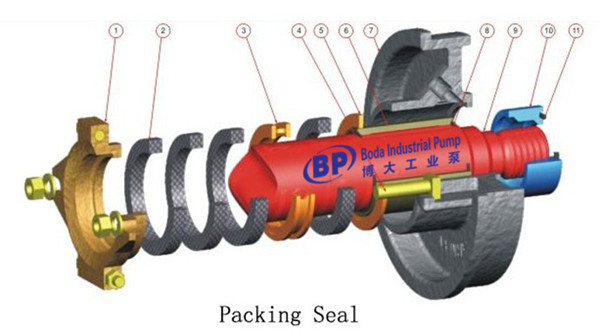

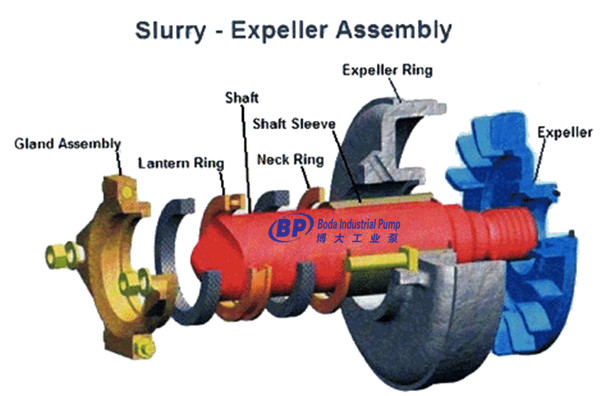

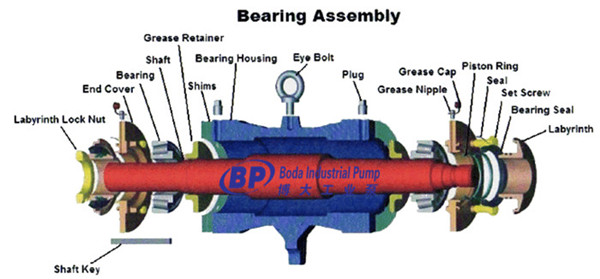

Rubber Lined Slurry Pump Structure:

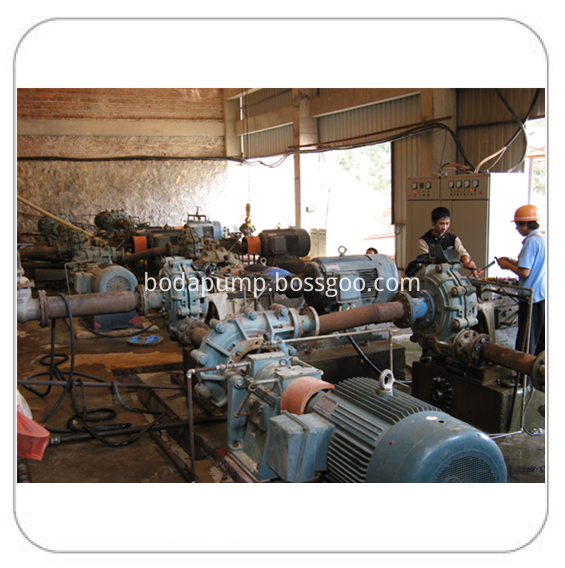

Rubber Lined Slurry Pump Application:

Related Keywords