10 Inch Centrifugal Horizontal Slurry Pump

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, SHANGHAI, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Productivity: | 300sets/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,SHANGHAI,Ningbo |

Pump Application

The BH series pumps apply to Alumina,Copper mining,Iron ore,Gas oil,Coal ,Electric industry,Phosphate,Bauxite,Gold,Potash, Wolfram,Water sewerage utilities,Sugar,Tobacco,Chemical fertilizer.

Pump Feature

- High head & High pressure & High Efficiency

- Anti-corrosive and wear resistant wet end parts

- Long working life

- Easy to maintain

- Exchanged with other pumps

Production Introduction

Pump Description

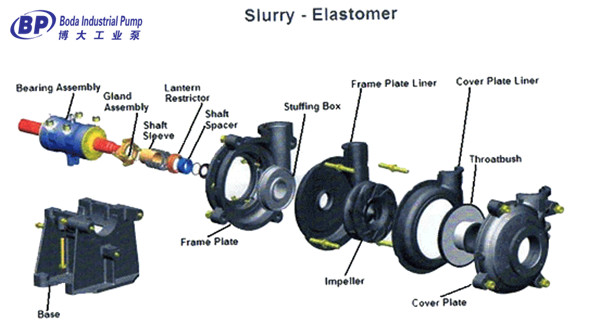

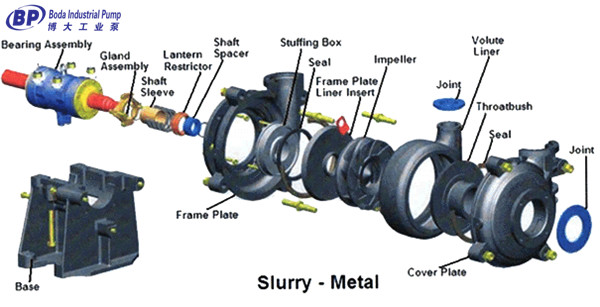

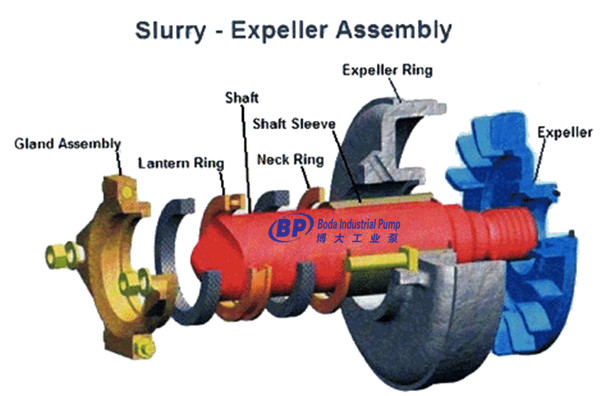

Type BH pump are cantilevered,horizontal,centrifugal slurry pumps. They are suitable for delivering low density slurry for metallurgical,mining,coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal. And it could operate in high speed with small volumes to save floor area. The frame plates have changeable,wear-resistant metal liners rubber liners and the impeller are made of wear-resistant metal or rubber.

Material: The wet parts material of BH pumps could be Cr27,Cr28,CD4MCu,PU, rubber liner material, High chrome alloy material could be wear resistant and corrosive resistant.

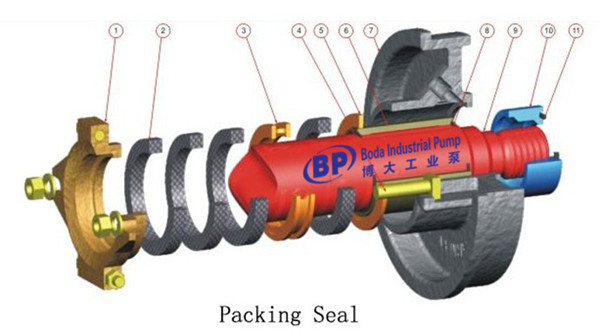

Seal: Gland packing seal, Mechanical seal, expeller seal.

Horizontal Abrasion & Corrosion Resistant Slurry Pump Performance Table:

|

Type

|

Allowable Mating Max.Power(kw)

|

Clear Water Performance

|

Impeller

|

||||||

|

Capacity Q

|

Head

H

(m) |

Speed

n

(r/min) |

Max EFF η(%)

|

NPSH)

(m) |

No of Vanes

|

Impel Dia(mm)

|

|||

|

(m3/h)

|

(L/S)

|

||||||||

|

1.5/1B-BH

|

15

|

12.6-28.8

|

3.5-8

|

6-68

|

1200-3800

|

40

|

2-4

|

5

|

152

|

|

2/1.5B-BH

|

15

|

32.4-72

|

9-20

|

6-58

|

1200-3200

|

45

|

3.5-8

|

5

|

184

|

|

3/2C-BH

|

30

|

39.6-86.4

|

11-24

|

12-64

|

1300-2700

|

55

|

4-6

|

5

|

214

|

|

4/3C-BH

|

30

|

86.4-198

|

24-55

|

9-52

|

1000-2200

|

71

|

4-6

|

5

|

245

|

|

4/3D-BH

|

60

|

||||||||

|

6/4D-BH

|

60

|

162-360

|

45-100

|

12-56

|

800-1550

|

65

|

5-8

|

5

|

365

|

|

6/4E-BH

|

120

|

||||||||

|

6/4D-BH

|

60

|

180-396

|

50-110

|

7-61

|

600-1600

|

55

|

3-8

|

4

|

372

|

|

6/4E-BH

|

120

|

||||||||

|

8/6E-BH

|

120

|

360-828

|

100-230

|

10-61

|

500-1140

|

72

|

2-9

|

5

|

510

|

|

8/6R-BH

|

300

|

||||||||

|

8/6E-BH

|

120

|

360-828

|

100-230

|

7-52

|

400-1000

|

70

|

2.5-6

|

4

|

536

|

|

8/6R-BH

|

300

|

360-828

|

100-230

|

7-52

|

400-1000

|

70

|

2.5-6

|

4

|

536

|

|

10/8ST-BH

|

560

|

612-1368

|

170-380

|

11-61

|

400-850

|

71

|

4-10

|

5

|

686

|

|

12/10ST-BH

|

560

|

936-1980

|

260-550

|

7-68

|

300-800

|

82

|

6

|

5

|

762

|

|

14/12ST-BH

|

560

|

1260-2772

|

350-770

|

13-63

|

300-600

|

77

|

3-10

|

5

|

965

|

|

16/14ST-BH

|

560

|

1368-3060

|

380-850

|

11-63

|

250-550

|

79

|

4-10

|

5

|

1067

|

|

16/14TU-BH

|

1200

|

||||||||

|

10/8E-BM

|

120

|

540-1440

|

150-400

|

14-60

|

600-1100

|

73

|

4-10

|

5

|

549

|

* Dimensionally Interchangeable :

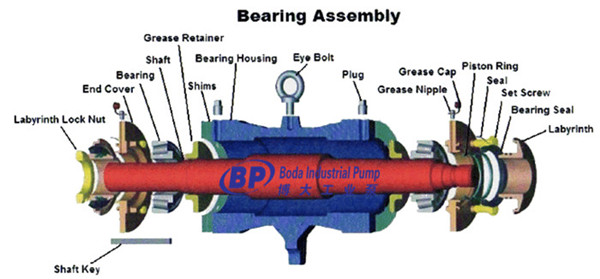

Horizontal Abrasion & Corrosion Resistant Slurry Pump Structure:

Horizontal Abrasion & Corrosion Resistant Slurry Pump Application:

Related Keywords