Gland Packing Seal Slurry Mud Mine Pumps

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, SHANGHAI, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Productivity: | 300sets/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,SHANGHAI,Ningbo |

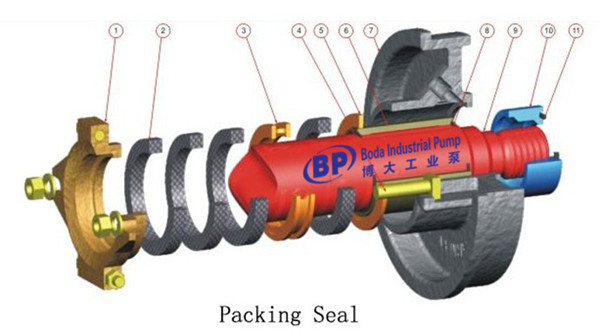

Gland Packing Seal Slurry Mud Mine Pumps

1. low noise and vibration

2. metal or rubber liner

3. corrosion resistance

4. good sealing effects

5. we can change the colors as you need

6. we have the quality stander ensure

7. smooth operation and high efficiency

8. quick-wear parts has a long life

Application:

The slurry pumps are designed for delivering abrasive, large particle and high-density slurries and applied over the fields such as metallurgy, mining, coal, power, building materials, and environmental protection.

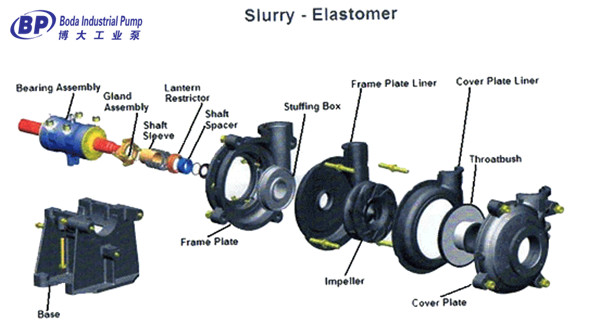

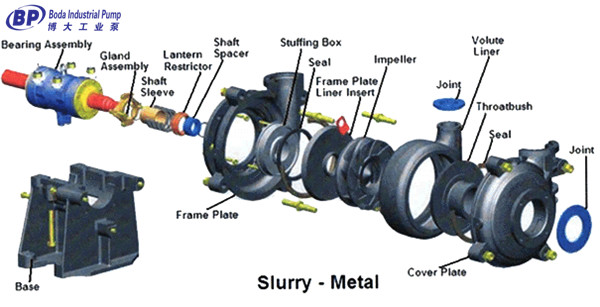

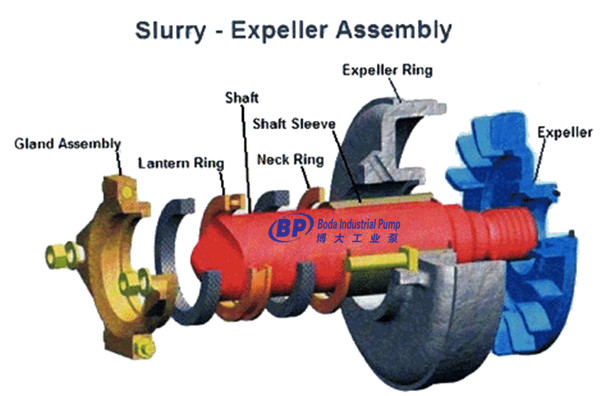

Structure characteristics:

1: Adopts horizontal, vertical axis medium open type double pump shell structure, lining for cemented carbide or rubber has good wear-resisting, corrosion resistance and high reliability

2: High efficiency hard alloy, and low NPSH

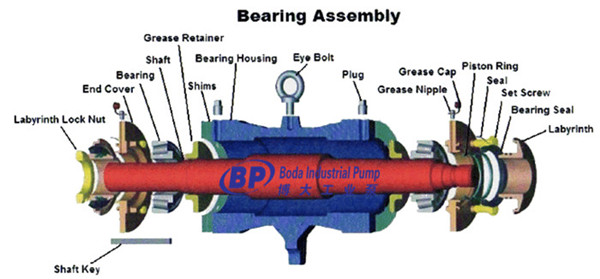

3: to meet the different operation conditions, adopted the brief type structure bearing parts, selected high bearing capacity design, alloy bearing grease lubrication oil.

4: through adjusting the clearance between protection board and impeller, ensuring the pump efficient operation

5: using packing seal, impeller sealing , container type mechanical seal to adapt to different operating mode requirement

6: Pump and drive can choose straight league transmission, triangle, hydraulic transmission device coupled transmission, reducer drive

7: the outflow direction can be installed by eight Angle rotation to adapt to different site installation conditions

8: available to use multipole series, to satisfy the long-distance transmission requirements.

Slurry Pump Performance Table:

|

Type

|

Allowable Mating Max.Power(kw)

|

Clear Water Performance

|

Impeller

|

||||||

|

Capacity Q

|

Head

H

(m) |

Speed

n

(r/min) |

Max EFF η(%)

|

NPSH)

(m) |

No of Vanes

|

Impel Dia(mm)

|

|||

|

(m3/h)

|

(L/S)

|

||||||||

|

1.5/1B-BH

|

15

|

12.6-28.8

|

3.5-8

|

6-68

|

1200-3800

|

40

|

2-4

|

5

|

152

|

|

2/1.5B-BH

|

15

|

32.4-72

|

9-20

|

6-58

|

1200-3200

|

45

|

3.5-8

|

5

|

184

|

|

3/2C-BH

|

30

|

39.6-86.4

|

11-24

|

12-64

|

1300-2700

|

55

|

4-6

|

5

|

214

|

|

4/3C-BH

|

30

|

86.4-198

|

24-55

|

9-52

|

1000-2200

|

71

|

4-6

|

5

|

245

|

|

4/3D-BH

|

60

|

||||||||

|

6/4D-BH

|

60

|

162-360

|

45-100

|

12-56

|

800-1550

|

65

|

5-8

|

5

|

365

|

|

6/4E-BH

|

120

|

||||||||

|

6/4D-BH

|

60

|

180-396

|

50-110

|

7-61

|

600-1600

|

55

|

3-8

|

4

|

372

|

|

6/4E-BH

|

120

|

||||||||

|

8/6E-BH

|

120

|

360-828

|

100-230

|

10-61

|

500-1140

|

72

|

2-9

|

5

|

510

|

|

8/6R-BH

|

300

|

||||||||

|

8/6E-BH

|

120

|

360-828

|

100-230

|

7-52

|

400-1000

|

70

|

2.5-6

|

4

|

536

|

|

8/6R-BH

|

300

|

360-828

|

100-230

|

7-52

|

400-1000

|

70

|

2.5-6

|

4

|

536

|

|

10/8ST-BH

|

560

|

612-1368

|

170-380

|

11-61

|

400-850

|

71

|

4-10

|

5

|

686

|

|

12/10ST-BH

|

560

|

936-1980

|

260-550

|

7-68

|

300-800

|

82

|

6

|

5

|

762

|

|

14/12ST-BH

|

560

|

1260-2772

|

350-770

|

13-63

|

300-600

|

77

|

3-10

|

5

|

965

|

|

16/14ST-BH

|

560

|

1368-3060

|

380-850

|

11-63

|

250-550

|

79

|

4-10

|

5

|

1067

|

|

16/14TU-BH

|

1200

|

||||||||

|

10/8E-BM

|

120

|

540-1440

|

150-400

|

14-60

|

600-1100

|

73

|

4-10

|

5

|

549

|

* Dimensionally Interchangeable

Horizontal Abrasion & Corrosion Resistant Slurry Pump Structure:

Horizontal Abrasion & Corrosion Resistant Slurry Pump Application:

Related Keywords