Oil Lubrication Bearing Assembly Slurry Pump

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Ningbo, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Productivity: | 300sets/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Ningbo,Shanghai |

High quality wear resistance TZ slurry pump

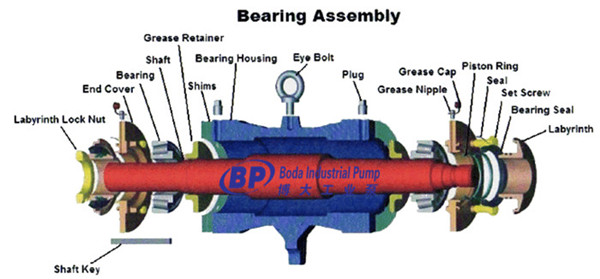

The TZ High quality wear resistance slurry pump are robust state of the art slurry pumps that feature oilor grease lubrication bearing assemblies and complete interchangeable with other major brands. The TZ Horizontal direct coupling ore slurry pump can be supplied in either a packed gland version using expeller technology, or mechanical seal system specifically designed for heavy duty slurry applications.

Features of High quality wear resistance TZ slurry pump

Choice of piston ring style labyrinth or other new style of water proof

Fully interchangeable with the common brand reducing inventory hold requirements

A full range of mechanical seal adaptations available upon request

Oil lubrication or packed grease

Painted to customer specifications upon request

A complete range of build specifications

Rubber lined with rubber impeller

Rubber lined with metal impeller

All metal lined using white iron chrome alloys

Slurry Pump Shaft Seal:

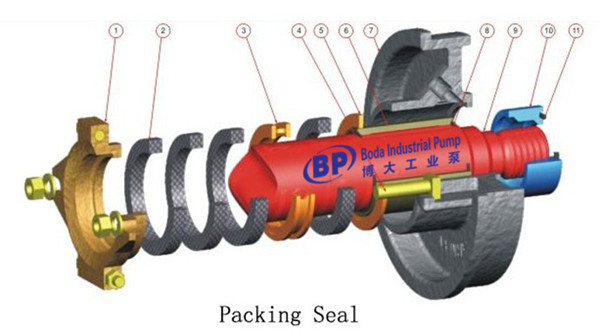

Packing Seal :As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available.

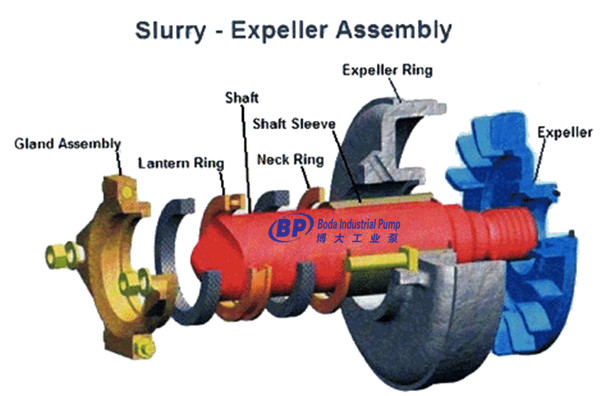

Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical Seal :TZ series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

Slurry Pump Application:

Related Keywords