Ash Slurry Sewage Pumps

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Xingang, Horgos, Yunnan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500 sets per month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO90001 |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air |

| Port: | Xingang,Horgos,Yunnan |

Introduction:

TZS slurry sewage pump is horizontal centrifugal heavy duty slurry pump and it is designed for the continuous pumping of high abrasive, high density slurries with minimal maintenance requirements. It will maintain high efficiency over the wear life of its components. The rubber and metal lined pumps feature casings which are radially split into two halves. Minimum casing bolts reduce maintenance and minimise downtime. The pumps of HS can be installed as multi-stage series.

Advantages:

1. Discharge branch can be positioned at intervals of 45 degree.

2. Good replaceability of components with original pump.

3. Wear-resistant metal and long service life time.

4. With greater axial and radial load rating capacity,

5. Discharge direction can be installed at intervals of 45 degrees as request and oriented to any eight positions to suit applications.

6. Suit different working condition

7. Wide application, high efficiency and easy to maintain.

8. Wide options for impeller.

9. Bearing assembly use grease lubrication.

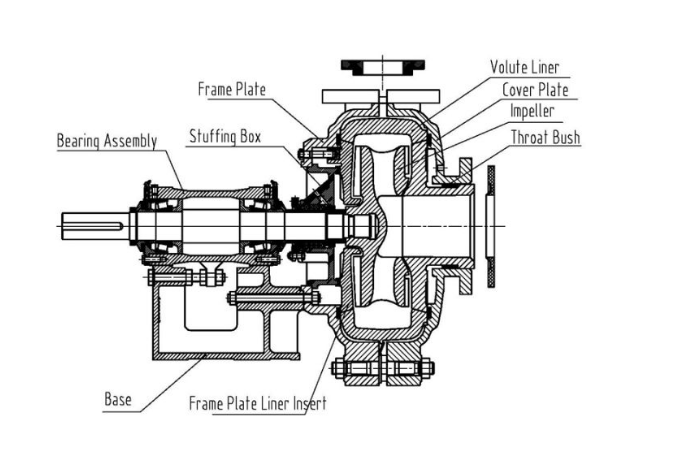

Construction:

The TZS type Horizontal Centrifugal Heavy Duty Mining Slurry Pump have pump bodies that consist of replaceable wear-resistant metal liners or wear-resistant rubber liners, and impellers can also apply wear-resistant metal material or wear-resistant rubber material. The TZHH type slurry pumps only apply wear-resistant metal material as their pump bodies and impellers.

Application:

TZS series slurry pump is widely used in metallurgy, mining, mineral processing, dredging, dewatering, water treatment, coal washing, mill, cyclone feed, tailing, power, building material...etc. various industrial sites. Slurry pumps are called different names for different working duties: Mineral processing pump, Mill discharge slurry Pump, Booster pump, Feeding pump, Tailing pump, Transfer pump Thickner Underflow Pump, De-watering screen pump, Pressure pump, Concentrate pump...

When or where you need Slurry Pump?

• To pump a medium where abrasive particles are present

• To transport the productions required or as much solids as possible hydraulically

The medium with few particles or not abrasive, which means the medium similar clear water that you could use clear water pumps, dirty water pumps or mud /sludge pumps is good enough

Related Keywords