Head High Chrome High Head Slurry Pump

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Qiangdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Productivity: | 200sets/month |

| Supply Ability: | 500 sets/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qiangdao,Shanghai |

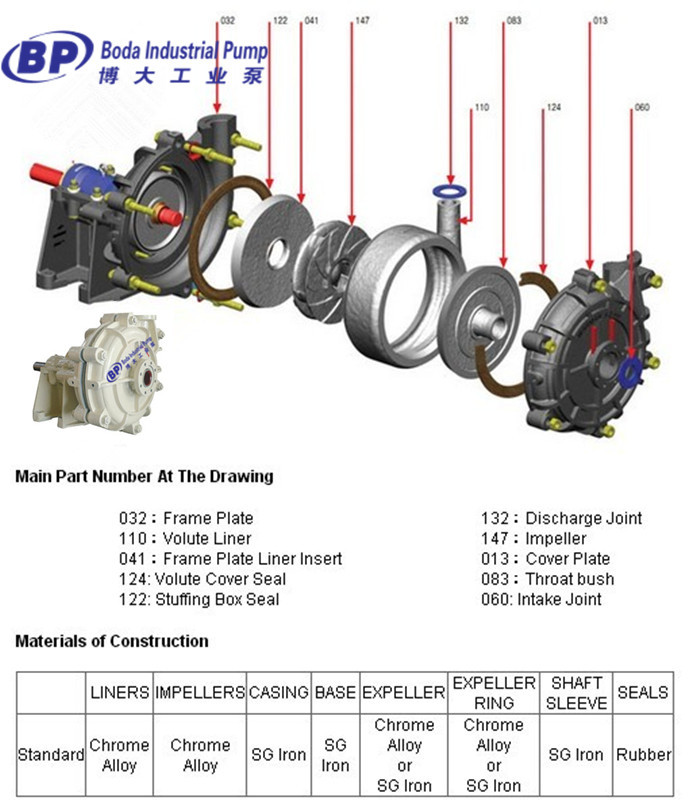

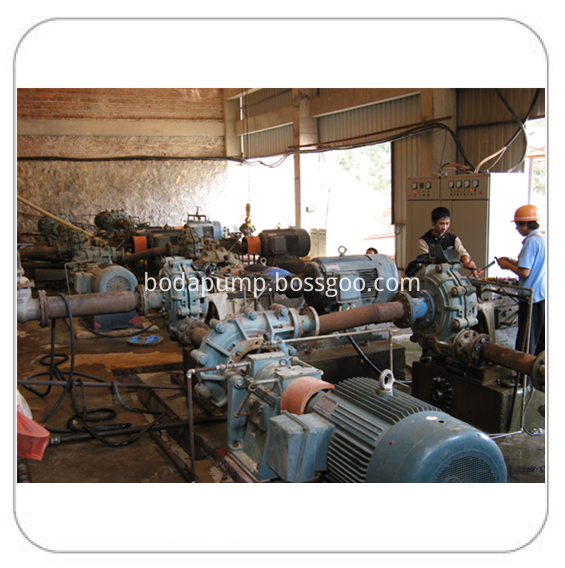

Head High Chrome High Head Slurry Pumps:

Type High Head BHH series slurry pumps are cantilevered, horizontal, centrifugal slurry pumps. They are designed for the handling highly abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments etc. The pumps of this type also may be installed in multistage series.

The frame plate liner and impeller for BHH pump are adoptable of wear-resistant metal only.

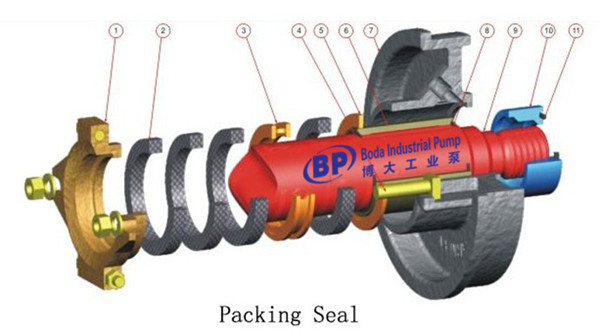

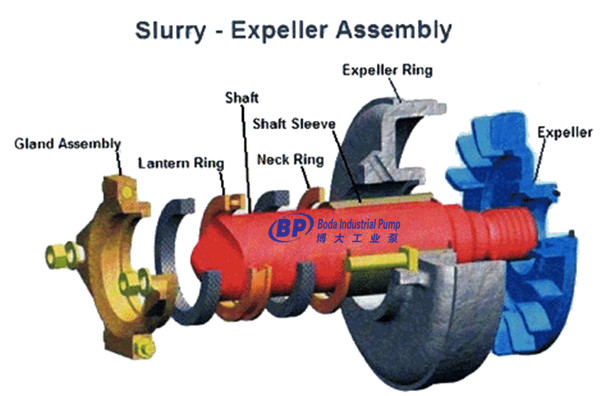

The shaft seals for type BHH pumps may be adoptable of gland seal or expeller seal. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

PUMP PARTS MATERIALS

|

Rubber Pumps Material |

Metal Pumps Material |

||||

|

No |

Part |

Material |

No |

Part |

Material |

|

1 |

Base |

Cast Iron |

1 |

Base |

Cast Iron |

|

2 |

Shaft |

4140 High Tensile Steel* |

2 |

Shaft |

4140 High Tensile Steel* |

|

3 |

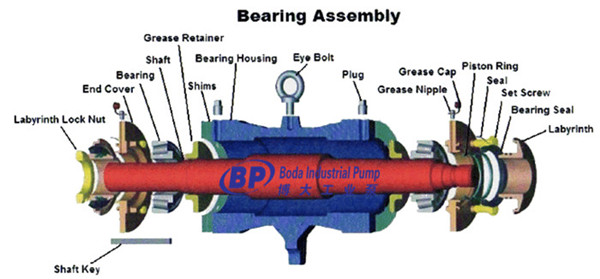

Bearing Assembly |

Timken (Cast Iron Body) |

3 |

Bearing Assembly |

Timken (Cast Iron Body) |

|

4 |

Shaft Sleeve |

420 Stainless Steel |

4 |

Shaft Sleeve |

420 Stainless Steel |

|

5 |

Pump Casing |

Cast Iron |

5 |

Pump Casing |

Cast Iron |

|

6 |

Frame Plate Liner Insert |

Rubber |

6 |

Frame Plate Liner |

27% Chrome White Iron |

|

7 |

Cover Plate Liner |

Rubber |

7 |

Volute Liner |

27% Chrome White Iron |

|

8 |

Impeller |

Rubber Coated High Tensile Steel |

8 |

Impeller |

27% Chrome White Iron |

|

9 |

Throat Bush |

Rubber |

9 |

Throat Bush |

27% Chrome White Iron |

|

10 |

Cover Plate |

Cast Iron |

10 |

Joint Rings |

Rubber |

|

11 |

Stuffing Box |

Cast Iron |

11 |

Cover Plate |

Cast Iron |

|

12 |

Expeller |

27% Chrome White Iron |

12 |

Stuffing Box |

Cast Iron |

|

13 |

Expeller Ring |

Natural Rubber |

13 |

Expeller |

27% Chrome White Iron |

|

14 |

Bolts |

Zinc Plated Steel |

14 |

Expeller Ring |

Natural Rubber |

|

15 |

O-rings |

Nitrile Rubber |

15 |

Bolts |

Zinc Plated Steel |

|

16 |

Seals |

Rubber |

16 |

O-rings |

Nitrile Rubber |

|

17 |

Seals |

Rubber |

17 |

Seals |

Rubber |

e Selection:Type Selection:

Refering to the performance curves of the pumps the selected capacity range should be as follows:

Pump type BHH: 40%-80% for medium density, medium abrasive slurries

40%-100% for lower density, lower abrasive slurries

High Head Horizontal Centrifugal Slurry Pump Type Selection Chart:

High Head Horizontal Centrifugal Slurry Pump Performance Table:

|

Pump Model |

Allowable Max. Power(kw) |

Clear Water Performance |

|

|||||

|

capacity Q |

Head H(m) |

speed n(r/min) |

Max.eff. η% |

NPSH (m) |

Impeller Dia(mm) |

|||

|

m3/h |

l/s |

|||||||

|

1.5/1C-BHH |

30 |

16.2-34.2 |

4.5-9.5 |

25-92 |

1400-2200 |

20 |

2-5.5 |

330 |

|

3/2D-BHH |

60 |

68.4-137 |

19-38 |

25-87 |

850-1400 |

47 |

3-7.5 |

457 |

|

4/3E-BHH |

120 |

126-252 |

35-70 |

12-97 |

600-1400 |

50 |

2-5 |

508 |

|

6/4F-BHH |

560 |

324-720 |

90-200 |

30-118 |

600-1000 |

64 |

3-8 |

711 |

|

8/6S-BHH |

560 |

468-1008 |

130-280 |

20-94 |

500-1000 |

65 |

4-12 |

711 |

High Head Horizontal Centrifugal Slurry Pump Structure:

Horizontal Abrasion & Corrosion Resistant Slurry Pump Application:

Related Keywords