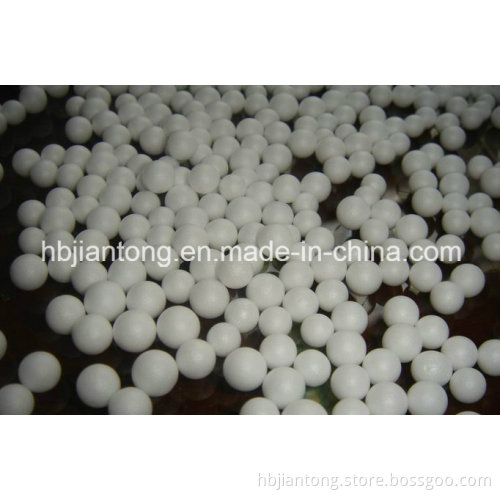

EPS Raw Material EPS Granule|Expandable Polystyrene EPS Granule (High Quality)

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Hot Sale EPS Expandable Polystyrene Resin Granules

Product Description

1. Detailes:

1). Name: EPS (Expandable Polystyrene)

2). Type: Virgin&Recycled

3). Grade: General&Flame retardant

4). Factory supply directly

6). Long term supply

2. Main Usage

1). Packaging: I. E.: Vegetable and fruit box, Fish box, Electronics packaging;

2). New Building Material: I. E.: Sandwich panel, 3D panel, Brick insert, Insulated Concrete Foam (ICF)

3). Plastic Foam Flotation: I. E.: Float

4). Decorating Material: I. E.: Cornices, Ceiling tiles, Articles in arts and crafts for advertisement and decoration;

5). Full Mould Casting: I. E.:

6). Protecting material: I. E.: Anti-freeze pad to cushion foundations of roads and railways in high cold region;

7). Filter material: I. E.: Applicable in medium and small scaled water supply system;

8). Other applications: I. E.: Applicable in seeding nurseries for hydroponics; Mixed with clay and cement to manufacture lightweight wall tiles and cement castings; As filling material for pillow...

Product Description

1. Detailes:

1). Name: EPS (Expandable Polystyrene)

2). Type: Virgin&Recycled

3). Grade: General&Flame retardant

4). Factory supply directly

6). Long term supply

2. Main Usage

1). Packaging: I. E.: Vegetable and fruit box, Fish box, Electronics packaging;

2). New Building Material: I. E.: Sandwich panel, 3D panel, Brick insert, Insulated Concrete Foam (ICF)

3). Plastic Foam Flotation: I. E.: Float

4). Decorating Material: I. E.: Cornices, Ceiling tiles, Articles in arts and crafts for advertisement and decoration;

5). Full Mould Casting: I. E.:

6). Protecting material: I. E.: Anti-freeze pad to cushion foundations of roads and railways in high cold region;

7). Filter material: I. E.: Applicable in medium and small scaled water supply system;

8). Other applications: I. E.: Applicable in seeding nurseries for hydroponics; Mixed with clay and cement to manufacture lightweight wall tiles and cement castings; As filling material for pillow...

| Type | Grade | Particle size (mm) | Foam density (g/l) | Principal Applications |

| E series | MS | 1.2-1.8 | 12-14 | Low density block molding. |

| Regular Grade | SA | 0.9-1.4 | 14-17 | Low density and thick wall shape molding |

| SB | 0.7-1.1 | 15-20 | Good fusion and surface finish | |

| S | 0.5-0.9 | 20-30 | Small parts and thin wall with good surface finish | |

| 4S | 0.3-0.6 | 30-50 | Small parts and thin wall with good surface finish | |

| HC series | MS | 1.2-1.8 | 12-14 | Large boxes with high gloss, high strength |

| High Gloss Rigid High Strength | SA | 0.9-1.4 | 14-17 | Medium boxes,parts require high strength. |

| SB | 0.7-1.1 | 15-20 | Small boxes with high gloss, high strength | |

| S | 0.5-0.9 | 20-30 | Thick parts with good surface and high strength | |

| L | 1.6-2.5 | 12-13 | Low density blocks | |

| ML | 1.4-2.2 | 12-15 | Low density blocks | |

| F series | MS | 1.2-1.8 | 13-17 | Low density blocks |

| High expansion low density Fire retardant | SA | 0.9-1.4 | 15-20 | Good fusion and surface finish |

| SB | 0.7-1.1 | 18-25 | Good fusion and surface finish | |

| S | 0.5-0.9 | 25-35 | High density blocks and shapes | |

| MS | 1.2-1.8 | 8-9 | Two times expansion ,light density for fire retardant block | |

| SA | 0.9-1.4 | 9-10 | ||

| SB | 0.7-1.1 | 10-13 | ||

| S | 0.5-0.9 | 11-15 | ||

| B series | MS | 1.2-1.8 | 14-18 | Fast cycling block molding |

| Fast cycle | SA | 0.9-1.4 | 17-22 | Fast cycling large packaging use |

| SB | 0.7-1.1 | 18-25 | Fast cycling shape molding,good fusion and surface finish | |

| S | 0.5-0.9 | 20-30 | Fast cycling small and thin wall shape molding | |

| 4S | 0.3-0.6 | 35-50 | Fast cycling small and thin wall shape molding | |

| P series | MS | 1.2-1.8 | 10-12 | one time expansion,easily achieve light density and economic consumption for block |

| Multiple Expansions Ultra Low Density | SA | 0.9-1.4 | 12-14 | |

| SB | 0.7-1.1 | 13-15 | ||

| S | 0.5-0.9 | 15-20 | ||

| 4S | 0.3-0.6 | 20-35 | ||

| MS | 1.2-1.8 | 5-7 | Multiple-passed expansion( 3-5 times),ultra-light block applications,light cushioning applications. | |

| SA | 0.9-1.4 | 6-8 | ||

| SB | 0.7-1.1 | 8-10 |

Related Keywords

Related Keywords