Crack reinforcement Heat Resistant Materials, PP Fiber for Concrete

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

pp fiber Company Information DFL Minmet Refactory Corp.Our company founded in 2004, running ISO 9001-2008 quality management system, the only Asia member of TVA( The Vermiculite Association) . Our main products include non-metal mineral products, such as Muscovite mica/Perlite/vermiculite/Sepiolite/kaolin,etc. Our products are exported to Japan and South Korea,Southeast Asia,Europe,America,Middle East and Africa. We do hope to serve you this time. Product Description Polypropylene staple fiber, also known as: crack fiber, pp fiber, building materials, construction fiber, is a kind of beam monofilament fibers, using polypropylene as the main raw material,and unique production process and high intensity. Put DFL PP fiber into the concrete or mortar, can effective prevent temperature change,micro-crack.The fiber can improve the property of anti-crack,anti-infiltration,anti-concussion and anti-shock of the concrete. SPECIFICATION:

Material--------------------------Polypropylene Fiber

Density(g/cm3) ---------------- 0.91

Elastic Modulas (MPa)--------3500min.

Length(mm) --------------------19

Equivalent Diameter (um) ----30

Shape ----------------------------monofilament

Crack Elongation(%)-----------10 min.

Acid &Alkali Resistance ------Strong

Water-Absorbency -------------No

Tensile Strength(GPa)--------- 550

Melting Point(°C) -------------160-170 The excellent performance after fill the pp fiber into concrete : a) , Improve the crack resistance of mortar and concrete b) , Greatly improve the permeability resistance of concrete , the ability to resist infiltration will enhance 60%~70% , c), Significantly improve the shock resistance and abrasion resistance performance of concrete , d) , Improve the antifreeze performance of concrete, put polypropylene fiber into concrete , can reduce the effect of internal stress caused by temperature change of concrete, to prevent temperature crack extension . When the fiber is put into the concrete, the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing to friction and rubbing, and the fiber monofilament or net-like structure will fully stretch, thus the concrete is reinforced by a great number of polypropylene fibers. Functional: 1.Prevent concrete crazing effectively 2.Improve tensile strength of concrete. 3.Improve the concussion and resistance to wear of concrete. 4.Improve barrier property of concrete. Directions for Usage: 1.0.5 -1.5 kilograms per cubic meter of mortar/concrete mixed with fiber, made special requirements of concrete can be increased to 1.8 kg.2. mixing time: making fiber mortar/concrete, the mixing time should be appropriately increased 30 to 60 s, commodity concrete without time delay.3. operation modes: first of all, stirring into measuring good coarse and fine aggregate, sand and short fiber, mixing time point about half of the time.Then stir while joining measure good cement, water and other liquid components, the mixing time accounted for about half of the total mixing time. Note: mixing big liquidity pumping fiber concrete priority choose vertical forced mixer, preferable lie low liquidity concrete shaft mixer.Join the fiber concrete with normal concrete construction and maintenance process is exactly the same. Packaging & Shipping in 25KG plastic bags for shipment.

Product

Application

Application  Certificate

Certificate  Our Services If you have any question,pls feel free to inform us.

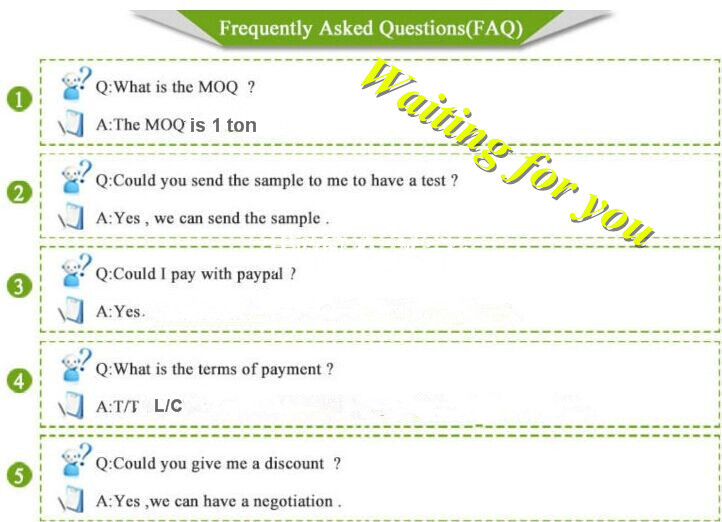

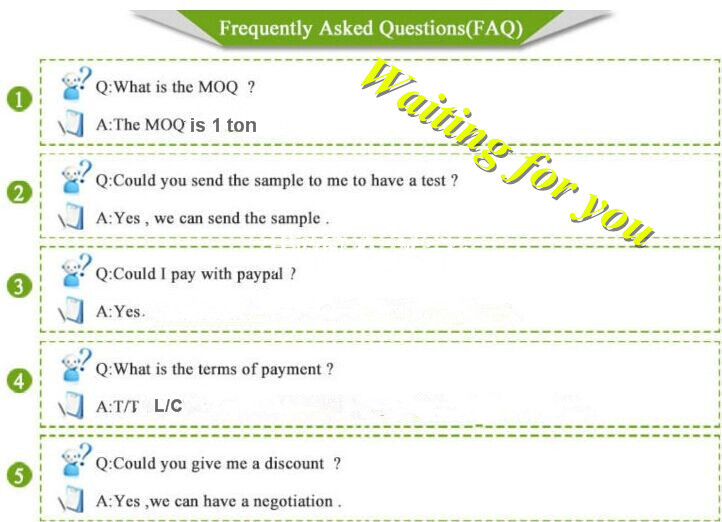

Our Services If you have any question,pls feel free to inform us.  FAQ

FAQ

Material--------------------------Polypropylene Fiber

Density(g/cm3) ---------------- 0.91

Elastic Modulas (MPa)--------3500min.

Length(mm) --------------------19

Equivalent Diameter (um) ----30

Shape ----------------------------monofilament

Crack Elongation(%)-----------10 min.

Acid &Alkali Resistance ------Strong

Water-Absorbency -------------No

Tensile Strength(GPa)--------- 550

Melting Point(°C) -------------160-170 The excellent performance after fill the pp fiber into concrete : a) , Improve the crack resistance of mortar and concrete b) , Greatly improve the permeability resistance of concrete , the ability to resist infiltration will enhance 60%~70% , c), Significantly improve the shock resistance and abrasion resistance performance of concrete , d) , Improve the antifreeze performance of concrete, put polypropylene fiber into concrete , can reduce the effect of internal stress caused by temperature change of concrete, to prevent temperature crack extension . When the fiber is put into the concrete, the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing to friction and rubbing, and the fiber monofilament or net-like structure will fully stretch, thus the concrete is reinforced by a great number of polypropylene fibers. Functional: 1.Prevent concrete crazing effectively 2.Improve tensile strength of concrete. 3.Improve the concussion and resistance to wear of concrete. 4.Improve barrier property of concrete. Directions for Usage: 1.0.5 -1.5 kilograms per cubic meter of mortar/concrete mixed with fiber, made special requirements of concrete can be increased to 1.8 kg.2. mixing time: making fiber mortar/concrete, the mixing time should be appropriately increased 30 to 60 s, commodity concrete without time delay.3. operation modes: first of all, stirring into measuring good coarse and fine aggregate, sand and short fiber, mixing time point about half of the time.Then stir while joining measure good cement, water and other liquid components, the mixing time accounted for about half of the total mixing time. Note: mixing big liquidity pumping fiber concrete priority choose vertical forced mixer, preferable lie low liquidity concrete shaft mixer.Join the fiber concrete with normal concrete construction and maintenance process is exactly the same. Packaging & Shipping in 25KG plastic bags for shipment.

Product

Application

Application  Our Services If you have any question,pls feel free to inform us.

Our Services If you have any question,pls feel free to inform us.  FAQ

FAQ

Related Keywords

Related Keywords

You May Also Like

You May Also Like