Tapered Roller Bearings / general bearing (32036X)

- Delivery Time:

- 25 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shandong, China (Mainland) |

|---|

Product Description

Product Description

Taper Roller Bearing:  We can satisfy your requirements

We can satisfy your requirements  Spherical Roller Bearings Details:

Spherical Roller Bearings Details:

Production Processes: No.1:Chemical composition of raw material inspection. High carbon chromium bearings steel Gcr15 is the standard material for precision bearing rings and balls.The material has uniform specification as AISL 52100(America),DIN100Cr6(Germany),JISSUJ2(Japan).

Production Processes: No.1:Chemical composition of raw material inspection. High carbon chromium bearings steel Gcr15 is the standard material for precision bearing rings and balls.The material has uniform specification as AISL 52100(America),DIN100Cr6(Germany),JISSUJ2(Japan).

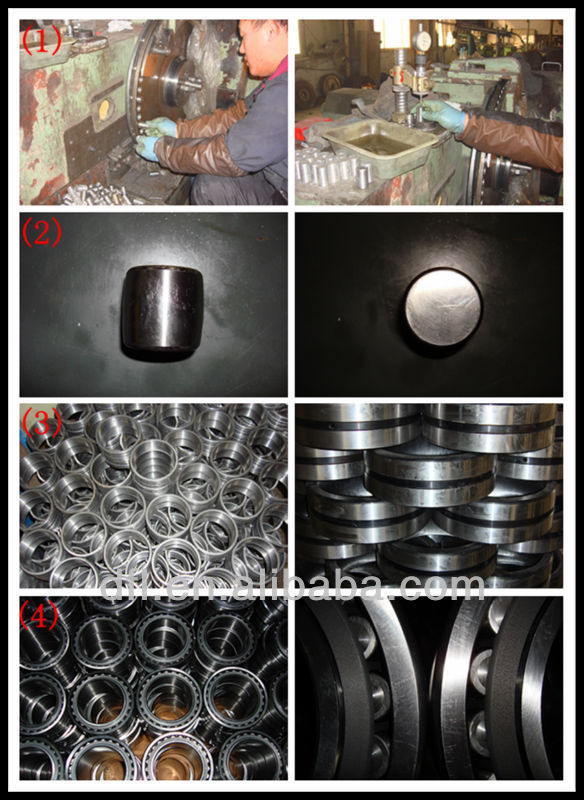

No.2:Forging. We will put the raw material for forging processing. No.3:Inner & outer rings grinding. 1).After forging,we will begin grinding preliminary.Heat treatment. 2).After the heat treatment , begin surface grinding 3).After the surface grinding, then begin the second grinding---Outer ring outer grinding and inner ring inner diameter grinding,Outer ring inner diameter grinding(raceway) and inner ring outer diameter grinding(raceway).Channel is polish highly. 4).Super finishing. Rings have the superfinish surface and the channel is polish highly.  PS: The bearings accuracy:

PS: The bearings accuracy:

No.4:Assembly. We need to put the inner ring,outer ring,steel ball,cage together,and then we need to fill the grease. PS:1.Lubrication: NSAR bearings include open type single or double shielded(Z,ZZ) and single or double sealed(RS,2RS).Before the shipment,we fill into the qualified oil or grease strictly.If you have any special request about the lubrication,please feel free to show us and we can fill the corresponding oil or grease with the accurate rate per your special request. 2.Vibration and noise: The vibration and noise of bearings are classified as four classes as Z1,Z2,Z3 and Z4.It is measured by the instrument of S0910-1.For special requirement,it is measured by BVT-1 and classified as V1,V2,V3 and V4. 3.Clearance: Clearance is gap amid bearing inner ring,outer ring,ball package.Bearing has radial clearance and axial clearance.  No.5:Packing. 1.Single box package : Generally 1piece/single plastic bag, then put it in single paper box, and the box with our brand NSAR or 3D,also can as your requirements.

No.5:Packing. 1.Single box package : Generally 1piece/single plastic bag, then put it in single paper box, and the box with our brand NSAR or 3D,also can as your requirements.

2.Industrial packing: Generally we use the plastic bag, single box, the carton, and the wood pallet.

3.As your requirements: The users who have any requirements in packing may write them down, then tell us. No.6:Transport.

No.6:Transport.  No.7:Shipping. We promise you ,we must be adhere to our delivery date!!!

No.7:Shipping. We promise you ,we must be adhere to our delivery date!!!  1.Why You Can Trust The Quality Of Our Productions! Because we have our own quality control points: Qcp 1,Chemical composition of raw material inspection. Qcp 2,Inner&outer rings turning inspection. Qcp 3,Hardness of material inspection. Qcp 4,Face grinding inspection. Qcp 5,Centerless grinding inspection. Qcp 6,Bore grinding inspection. Qcp 7,Groove curvature and groove shape inspection. Qcp 8,Roughness of groove and surface inspection. Qcp 9,Assembly inspection. Qcp 10,Grease filling inspection. Qcp 11,Noise & vibration testing inspection. Qcp 12,Packing & storing inspection before shipment.

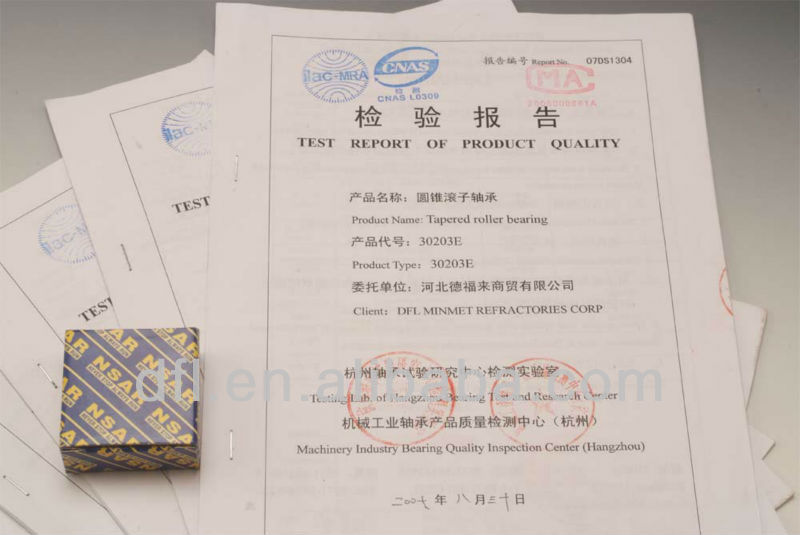

1.Why You Can Trust The Quality Of Our Productions! Because we have our own quality control points: Qcp 1,Chemical composition of raw material inspection. Qcp 2,Inner&outer rings turning inspection. Qcp 3,Hardness of material inspection. Qcp 4,Face grinding inspection. Qcp 5,Centerless grinding inspection. Qcp 6,Bore grinding inspection. Qcp 7,Groove curvature and groove shape inspection. Qcp 8,Roughness of groove and surface inspection. Qcp 9,Assembly inspection. Qcp 10,Grease filling inspection. Qcp 11,Noise & vibration testing inspection. Qcp 12,Packing & storing inspection before shipment.  Besides We have runned the ISO9001-2008 Quality System:

Besides We have runned the ISO9001-2008 Quality System:

2.Why You Can Trust Our Services! Because our convenient transport and rich experience. NSAR Bearings Factory,founded in 1995,is one of the largest suppliers of rolling bearings in China.Our factory is located in linQing city,Capital of Chinese bearings,which adjoins three main railway lines of Jing-Guang,Jing-Jiu and Jing-Hu.The transportation is convenient and the environment is graceful. Our trade department is professional and comprehensive team which based on production and trading business,running ISO9001-2008 quality system.It has almost 20 years export experience. Our Factory:

2.Why You Can Trust Our Services! Because our convenient transport and rich experience. NSAR Bearings Factory,founded in 1995,is one of the largest suppliers of rolling bearings in China.Our factory is located in linQing city,Capital of Chinese bearings,which adjoins three main railway lines of Jing-Guang,Jing-Jiu and Jing-Hu.The transportation is convenient and the environment is graceful. Our trade department is professional and comprehensive team which based on production and trading business,running ISO9001-2008 quality system.It has almost 20 years export experience. Our Factory:  Our Office Building:

Our Office Building:  3.Why you can choose our production! Because our products are extensively applied to: Motorcycles, Electric Bicycles, Electric Motors (Scooters), Electric Tools, Fans, Sports Apparatus, Washing Machines, Dust Collectors, Ventilators, Textile Machines, Running Machines (Treadmills), Household Appliances, Water Pumps, Agricultural Machines, Precision Machineries, etc. 4.Why you can contact us! Because we have every contact ways.And you can contact us anytime and we must be reply you in 24 hours. For more information, please be free to let me know. We'll do our best! Thank you for your support!

3.Why you can choose our production! Because our products are extensively applied to: Motorcycles, Electric Bicycles, Electric Motors (Scooters), Electric Tools, Fans, Sports Apparatus, Washing Machines, Dust Collectors, Ventilators, Textile Machines, Running Machines (Treadmills), Household Appliances, Water Pumps, Agricultural Machines, Precision Machineries, etc. 4.Why you can contact us! Because we have every contact ways.And you can contact us anytime and we must be reply you in 24 hours. For more information, please be free to let me know. We'll do our best! Thank you for your support!

We can satisfy your requirements

We can satisfy your requirements

Production Processes: No.1:Chemical composition of raw material inspection. High carbon chromium bearings steel Gcr15 is the standard material for precision bearing rings and balls.The material has uniform specification as AISL 52100(America),DIN100Cr6(Germany),JISSUJ2(Japan).

Production Processes: No.1:Chemical composition of raw material inspection. High carbon chromium bearings steel Gcr15 is the standard material for precision bearing rings and balls.The material has uniform specification as AISL 52100(America),DIN100Cr6(Germany),JISSUJ2(Japan). | Steel No. | Chemical composition % | ||||||||

| C | Si | Min | P | S | Cr | Mo | Cu | Ni | |

| Gcr15 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | s0.025 | s0.025 | 1.40-1.65 | No | s0.25 | s0.30 |

PS: The bearings accuracy:

PS: The bearings accuracy: | Standard allowable tolerance grades | |||||

| GB\T307.1 | P0 | P6 | P5 | P4 | P2 |

| ISO492 | Normal Class | Class6 | Class5 | Class4 | Class2 |

| JIS B 1514 | JIS 0 Grade | JIS 6 Grade | JIS 5 Grade | JIS 4 Grade | JIS 2 Grade |

| AFBMA STD.20 | ABEC-1 | ABEC-3 | ABEC-5 | ABEC-7 | ABEC-9 |

No.5:Packing. 1.Single box package : Generally 1piece/single plastic bag, then put it in single paper box, and the box with our brand NSAR or 3D,also can as your requirements.

No.5:Packing. 1.Single box package : Generally 1piece/single plastic bag, then put it in single paper box, and the box with our brand NSAR or 3D,also can as your requirements.2.Industrial packing: Generally we use the plastic bag, single box, the carton, and the wood pallet.

3.As your requirements: The users who have any requirements in packing may write them down, then tell us.

No.6:Transport.

No.6:Transport.  No.7:Shipping. We promise you ,we must be adhere to our delivery date!!!

No.7:Shipping. We promise you ,we must be adhere to our delivery date!!!  1.Why You Can Trust The Quality Of Our Productions! Because we have our own quality control points: Qcp 1,Chemical composition of raw material inspection. Qcp 2,Inner&outer rings turning inspection. Qcp 3,Hardness of material inspection. Qcp 4,Face grinding inspection. Qcp 5,Centerless grinding inspection. Qcp 6,Bore grinding inspection. Qcp 7,Groove curvature and groove shape inspection. Qcp 8,Roughness of groove and surface inspection. Qcp 9,Assembly inspection. Qcp 10,Grease filling inspection. Qcp 11,Noise & vibration testing inspection. Qcp 12,Packing & storing inspection before shipment.

1.Why You Can Trust The Quality Of Our Productions! Because we have our own quality control points: Qcp 1,Chemical composition of raw material inspection. Qcp 2,Inner&outer rings turning inspection. Qcp 3,Hardness of material inspection. Qcp 4,Face grinding inspection. Qcp 5,Centerless grinding inspection. Qcp 6,Bore grinding inspection. Qcp 7,Groove curvature and groove shape inspection. Qcp 8,Roughness of groove and surface inspection. Qcp 9,Assembly inspection. Qcp 10,Grease filling inspection. Qcp 11,Noise & vibration testing inspection. Qcp 12,Packing & storing inspection before shipment.  Besides We have runned the ISO9001-2008 Quality System:

Besides We have runned the ISO9001-2008 Quality System:

2.Why You Can Trust Our Services! Because our convenient transport and rich experience. NSAR Bearings Factory,founded in 1995,is one of the largest suppliers of rolling bearings in China.Our factory is located in linQing city,Capital of Chinese bearings,which adjoins three main railway lines of Jing-Guang,Jing-Jiu and Jing-Hu.The transportation is convenient and the environment is graceful. Our trade department is professional and comprehensive team which based on production and trading business,running ISO9001-2008 quality system.It has almost 20 years export experience. Our Factory:

2.Why You Can Trust Our Services! Because our convenient transport and rich experience. NSAR Bearings Factory,founded in 1995,is one of the largest suppliers of rolling bearings in China.Our factory is located in linQing city,Capital of Chinese bearings,which adjoins three main railway lines of Jing-Guang,Jing-Jiu and Jing-Hu.The transportation is convenient and the environment is graceful. Our trade department is professional and comprehensive team which based on production and trading business,running ISO9001-2008 quality system.It has almost 20 years export experience. Our Factory:  Our Office Building:

Our Office Building: Related Keywords

Related Keywords

You May Also Like

You May Also Like