ISO 9001 Industrial Electric Dust Collector or Filter Manufacture Price

- Delivery Time:

- 60 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

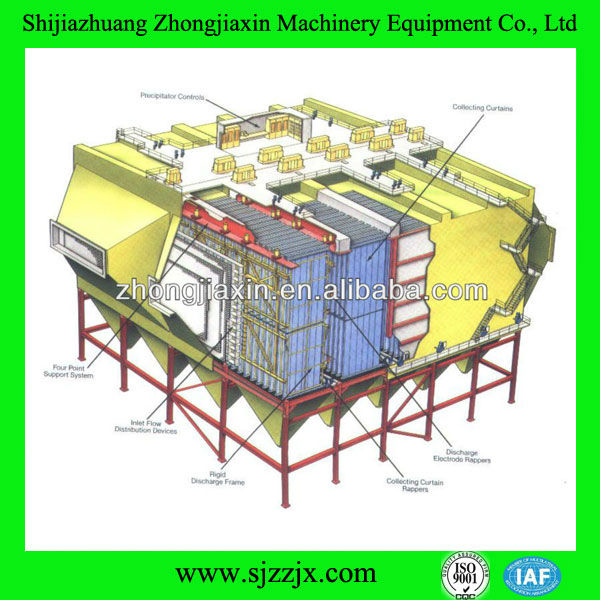

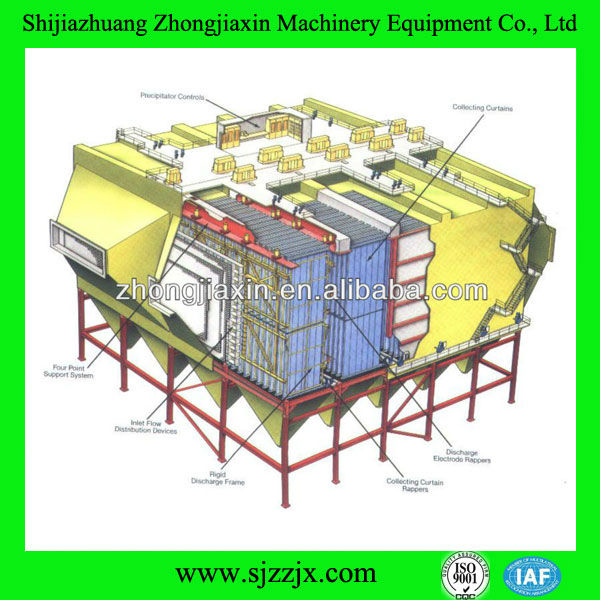

ISO 9001 Industrial Electric Dust Collector or Filter Manufacture Price  Industrial Dust Collector Advantages: 1. Strong adaptability,big capacity,good reliability 2. Can collect less than one micron of dust 3. Can handle 400 °C and higher than 400 °C dust air 4. Every hour can handle 100 cubic meters dust air 5. Little resistance during operation, easy maintenance, low operating cost 6. Widely used in thermal power station, black and non-ferrous metal smelting, cement, chemical, paper and other industries 7. We can according to the requirements of the customers or site conditions, design for users of the size of the special specification electrostatic precipitator Industrial Dust Collector Specification Data:

Industrial Dust Collector Advantages: 1. Strong adaptability,big capacity,good reliability 2. Can collect less than one micron of dust 3. Can handle 400 °C and higher than 400 °C dust air 4. Every hour can handle 100 cubic meters dust air 5. Little resistance during operation, easy maintenance, low operating cost 6. Widely used in thermal power station, black and non-ferrous metal smelting, cement, chemical, paper and other industries 7. We can according to the requirements of the customers or site conditions, design for users of the size of the special specification electrostatic precipitator Industrial Dust Collector Specification Data:

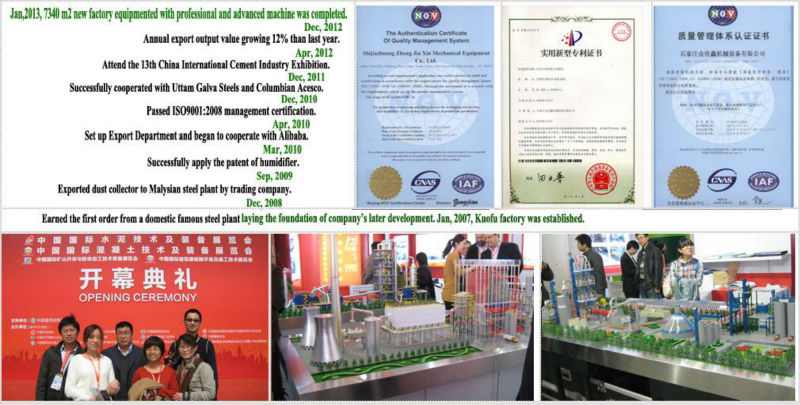

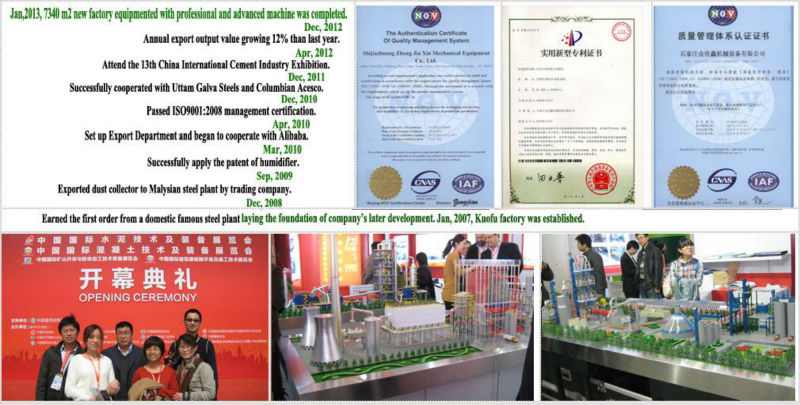

Customer Guidance: When you send an enquiry, please including the basic design factors in email: 1. What kind of factory the dust collector will be installed in? 2. The medium will be filtered? 3. The temperature at dust collector inlet? 4. The capacity? Because with these factors, we are able to give you a fast answer. Company Introduction &Main Products: Established in 2002 year, pass ISO9001:2008 Industry Dust collector- Bag Filter, ESP, Cyclone Dust Collector Bucket Elevator Scraper Conveyor Screw Conveyor Pneumatic Conveyor Advantage of Company: 1. Design: have our own Engineer term, each machine is designed as customer’s specific requirement, the performace is higher 20~40% than other factory with same cost. 2. Quality: Test machines and have commercial inspection before shipping, maintanence is lower 30%-50% than the same industry. 3. After-service: provide technical guidance freely during machine service life.

Customer Guidance: When you send an enquiry, please including the basic design factors in email: 1. What kind of factory the dust collector will be installed in? 2. The medium will be filtered? 3. The temperature at dust collector inlet? 4. The capacity? Because with these factors, we are able to give you a fast answer. Company Introduction &Main Products: Established in 2002 year, pass ISO9001:2008 Industry Dust collector- Bag Filter, ESP, Cyclone Dust Collector Bucket Elevator Scraper Conveyor Screw Conveyor Pneumatic Conveyor Advantage of Company: 1. Design: have our own Engineer term, each machine is designed as customer’s specific requirement, the performace is higher 20~40% than other factory with same cost. 2. Quality: Test machines and have commercial inspection before shipping, maintanence is lower 30%-50% than the same industry. 3. After-service: provide technical guidance freely during machine service life.

Industrial Dust Collector Advantages: 1. Strong adaptability,big capacity,good reliability 2. Can collect less than one micron of dust 3. Can handle 400 °C and higher than 400 °C dust air 4. Every hour can handle 100 cubic meters dust air 5. Little resistance during operation, easy maintenance, low operating cost 6. Widely used in thermal power station, black and non-ferrous metal smelting, cement, chemical, paper and other industries 7. We can according to the requirements of the customers or site conditions, design for users of the size of the special specification electrostatic precipitator Industrial Dust Collector Specification Data:

Industrial Dust Collector Advantages: 1. Strong adaptability,big capacity,good reliability 2. Can collect less than one micron of dust 3. Can handle 400 °C and higher than 400 °C dust air 4. Every hour can handle 100 cubic meters dust air 5. Little resistance during operation, easy maintenance, low operating cost 6. Widely used in thermal power station, black and non-ferrous metal smelting, cement, chemical, paper and other industries 7. We can according to the requirements of the customers or site conditions, design for users of the size of the special specification electrostatic precipitator Industrial Dust Collector Specification Data: | Model Item | SDD 10×3 | SDD 12.5×3 | SDD 15×3 | SDD 20×3 | SDD 25×3 | ||||

Effective cross sectional area(m2) | 10

| 12.6

| 15.1

| 20.2

| 25.1 | ||||

Capacity×104(m3/h) | 3.24-4.32 | 4.05-5.42 | 4.8-6.46 | 6.45-8.6 | 8.05-10.9 | ||||

Air speed(m/s) | 0.9-1.2 | ||||||||

Bearingpressure (pa) | -6000-0 | ||||||||

| Dust air temperature (°C) | ≤300 | ||||||||

Design efficiency (%) | ≥99 | ||||||||

Pressure loss(%) | ≤294 | ||||||||

Air leakage ratio(%) | <3 | ||||||||

No. of electric field/no. of chamber | 3 fileds/chambers | ||||||||

Electric field effective length (m) | 3.5×3=10.5 | ||||||||

High voltage power supply sets | 3sets | ||||||||

High voltage power supply current (A) | 0.1 | ||||||||

Voltage (KV) | 72 | ||||||||

Out Size L×W×H (m) | 14.8×5.6×10.41 | 14.8×5.6×11.21 | 14.8×5.6×11.51 | 14.8×5.6×12.51 | 14.8×5.6×13.1 | ||||

Customer Guidance: When you send an enquiry, please including the basic design factors in email: 1. What kind of factory the dust collector will be installed in? 2. The medium will be filtered? 3. The temperature at dust collector inlet? 4. The capacity? Because with these factors, we are able to give you a fast answer. Company Introduction &Main Products: Established in 2002 year, pass ISO9001:2008 Industry Dust collector- Bag Filter, ESP, Cyclone Dust Collector Bucket Elevator Scraper Conveyor Screw Conveyor Pneumatic Conveyor Advantage of Company: 1. Design: have our own Engineer term, each machine is designed as customer’s specific requirement, the performace is higher 20~40% than other factory with same cost. 2. Quality: Test machines and have commercial inspection before shipping, maintanence is lower 30%-50% than the same industry. 3. After-service: provide technical guidance freely during machine service life.

Customer Guidance: When you send an enquiry, please including the basic design factors in email: 1. What kind of factory the dust collector will be installed in? 2. The medium will be filtered? 3. The temperature at dust collector inlet? 4. The capacity? Because with these factors, we are able to give you a fast answer. Company Introduction &Main Products: Established in 2002 year, pass ISO9001:2008 Industry Dust collector- Bag Filter, ESP, Cyclone Dust Collector Bucket Elevator Scraper Conveyor Screw Conveyor Pneumatic Conveyor Advantage of Company: 1. Design: have our own Engineer term, each machine is designed as customer’s specific requirement, the performace is higher 20~40% than other factory with same cost. 2. Quality: Test machines and have commercial inspection before shipping, maintanence is lower 30%-50% than the same industry. 3. After-service: provide technical guidance freely during machine service life.

Related Keywords

Related Keywords

You May Also Like

You May Also Like