JCH metal roll forming machine series,metal frame wall panel and roof tile making machine

- Payment Type:

- T/T

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|---|

| Supply Ability: | 30 Set/Sets per Month can produce more metal shingle roll forming machine |

| Payment Type: | T/T |

1.High efficiency

2.Lower cost

3.Long life time

4.Pass ISO9001

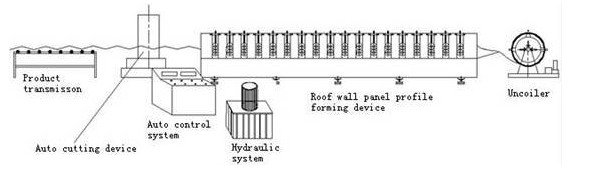

JCH metal roll forming machine series,metal frame wall panel and roof tile making machine Product Description The chart of process flow

Decoiling—active feeding (put the coil strip into the first feeding roller)—leveling —roll forming — computer control system—hydraulic cutting—product to stand Equipment technical parameters

Decoiling—active feeding (put the coil strip into the first feeding roller)—leveling —roll forming — computer control system—hydraulic cutting—product to stand Equipment technical parameters Molding host | Model | roof tile forming machine |

Forming size | 9000mm*1200mm*1000mm | |

weight | 4 T | |

Host big frame structure | Frame welded | |

Roll station | 20rows | |

Axial material | 45# steel | |

Out diameter of shaft | Φ75mm | |

Roller materials | 45# steel hard chromium plating | |

Drive | By chain | |

Sprocket chain | 1 inch | |

Main power: | 5.5kw | |

Working speed | 8-10 m/min | |

Material thickness | 0.3-0.8mm | |

| Made board | 16mm |

Material of blade | Cr12,heat treatment 60-62°C |

Shearing system | It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job. The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves. Power of the oil pump: 3kw Hydraulic oil :40# |

Main computer control cabinet | It adopts industrial computer to control. The target piece’s length is adjustable and digit of it can be adjusted. Computer mode has two modes: automatic and manual one. The system is easy to operate and use. Processing precision : within 1.00mm It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part. Transducer brand is EURA. The seller will provide Chinese and English language screen. |

The machine types we produce

The machine types we produce

Some panel types we can design

Some panel types we can design  Packaging & Shipping Paking the roll forming machine manufacturer

Packaging & Shipping Paking the roll forming machine manufacturer  The certifications we have

The certifications we have  Our Services We are responsible for the installation and debugging if you buy the standing seam roof roll machine .Equipment parts are guaranteed for one year, Within a year of equipment parts nonhuman damage(in addition to electric), we undertake free swap or maintenance for you. Any question,please call informed.If you need other equipments,welcome to land our website:en.alibaba.com Or you can contact me immediately:

Our Services We are responsible for the installation and debugging if you buy the standing seam roof roll machine .Equipment parts are guaranteed for one year, Within a year of equipment parts nonhuman damage(in addition to electric), we undertake free swap or maintenance for you. Any question,please call informed.If you need other equipments,welcome to land our website:en.alibaba.com Or you can contact me immediately:  Company Information Botou City ShiBo Machinery CO.,LTD. founded in 2001, specialized in Design, Manufacture, Installation, Debug of Color Steel Roll Forming Machine, is a private enterprise .With many years’experience, we have developed many new products of Profiling Equipment, which rich the Color Steel Profession, make our machinery more reasonable, artistic and practical and obtain the consistent high praise of the new and old customers.

Company Information Botou City ShiBo Machinery CO.,LTD. founded in 2001, specialized in Design, Manufacture, Installation, Debug of Color Steel Roll Forming Machine, is a private enterprise .With many years’experience, we have developed many new products of Profiling Equipment, which rich the Color Steel Profession, make our machinery more reasonable, artistic and practical and obtain the consistent high praise of the new and old customers. Related Keywords