OEM Aluminum Castings for Valves

- Delivery Time:

- 20 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

Material | 1.Sand casting&Gravity casting&Low pressure die casting: A356/A319/A413/ZL101/ZL102/ZL104/ZL107/LM6//LM/20/LM25/ENAC-42100/ ENAC-42200/EN AC-43000/ENAC-43200/EN AC-46000/EN AC-46200 2.High pressure die casting: A380/A390/A360/ADC10/ADC12/ENAC-43400/ENAC-44300/ENAC-44400/ENAC- 46000/ENAC-46100/ENAC-46200/ 3. CNC machining casting: 6061-T6/6063-T6 |

Process | Sand casting, Gravity casting, high pressure die casting, low pressure die casting and CNC Machining casting. |

Designs | As per the customer’s drawings or Samples |

Equipment of Casting | 1 High pressure die casting machining: 125T/180T/250T/280T/500T/800T/1250T 2 Gravity casting machine: 5 production lines 3 Low pressure die casting machining: 1 production line 4 Sand casting machine: 6 production lines 5 Degassing equipment and opportunities to refine the material 6 Machining: CNC Machine; Milling machine; Turning machining; drill and tap machine

|

Testing facility | spectrometer, tensile test machine, hardness test machine, CMM dimension report |

Standard | ASTM, DIN,JIS, EN, ISO, GB standards |

Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

Finished | Polishing,sand blasting,heat treatment,painting,powder coating,anodizing, electroplating,Chrome plating, mirror polishing. |

Service | OEM service available. |

Product | All kinds of aluminum casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on |

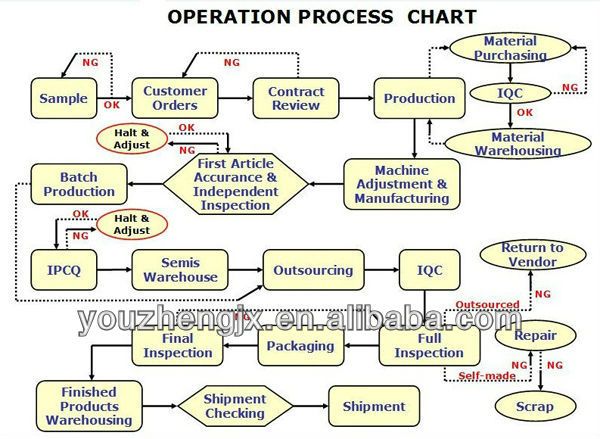

Advantage | 7 Have four casting types; 8 From Casting to Finished surface, Owned casting, polishing and plating workshops, We can offer Good quality and strict delivery time. 9 With samples and order: We can offer dimension report,Chemical composition and Mechanical properties 10 Control material with spectral and thermal analysis equipment (density and processing) 11 Spectral analysis of rawmaterial and liquid melt, batch before casting.

|

Inspection | 12 Foundry in-house 13 Third Party inspection available upon requirement

|

Packing | Carton Box with Pallet/Wooden Box/Steel Pallet |

Production:

Production:

Products:

Products:

Company Information Our Product Ranges: Precision Metal Stamping Parts--Hinges, Brackets, Custom Accessories for Auto, Furniture, Construction CNC Machining Parts Castings & Forgings Pipe Fittings, BW Fitting Ventilation parts, Duct Fittings Rubber and Plastic products FAQ Sample policy: If you want to check sample first, you need pay the sample charge and the charge will be refund to you when the mass order confirmed Price: If you want to know the price, please kindly confirm which product you need or send us your product's picture, so that we can provide you the best price with details Payment Terms: 1. T/T ( with 30% deposit ) , L/C at sight 2. Customers can choose which payment ways that you accept Shipping Terms: 1. Loading Port: TianJin, China 2. Samples Delivery: About 15-30 days after receiving the deposit Mass Production Delivery: General around 25-30 days after sample confirmed Packing Details: 1. Our general packing were carton with pallet 2. According to clients' specific requirements Our advantages: 1. Factory directly supply 2. Many years manufacture experience 3. Competitive and reasonable price 4. OEM service, we can do as your drawings or samples 5. Quality Guarantee 6. Good after-sale service 7. Timely delivery 8. High-tech CNC Machines 9. Independent Engineering Department 10.Kinds of surface treatment---Zinc Plating, Powder Coating, Anodizing, Chrome Plate, RoHs etc as your requirements Send us your enquiry and we guarantee to provide you with the best prices with top quality products and services

Company Information Our Product Ranges: Precision Metal Stamping Parts--Hinges, Brackets, Custom Accessories for Auto, Furniture, Construction CNC Machining Parts Castings & Forgings Pipe Fittings, BW Fitting Ventilation parts, Duct Fittings Rubber and Plastic products FAQ Sample policy: If you want to check sample first, you need pay the sample charge and the charge will be refund to you when the mass order confirmed Price: If you want to know the price, please kindly confirm which product you need or send us your product's picture, so that we can provide you the best price with details Payment Terms: 1. T/T ( with 30% deposit ) , L/C at sight 2. Customers can choose which payment ways that you accept Shipping Terms: 1. Loading Port: TianJin, China 2. Samples Delivery: About 15-30 days after receiving the deposit Mass Production Delivery: General around 25-30 days after sample confirmed Packing Details: 1. Our general packing were carton with pallet 2. According to clients' specific requirements Our advantages: 1. Factory directly supply 2. Many years manufacture experience 3. Competitive and reasonable price 4. OEM service, we can do as your drawings or samples 5. Quality Guarantee 6. Good after-sale service 7. Timely delivery 8. High-tech CNC Machines 9. Independent Engineering Department 10.Kinds of surface treatment---Zinc Plating, Powder Coating, Anodizing, Chrome Plate, RoHs etc as your requirements Send us your enquiry and we guarantee to provide you with the best prices with top quality products and services

Related Keywords