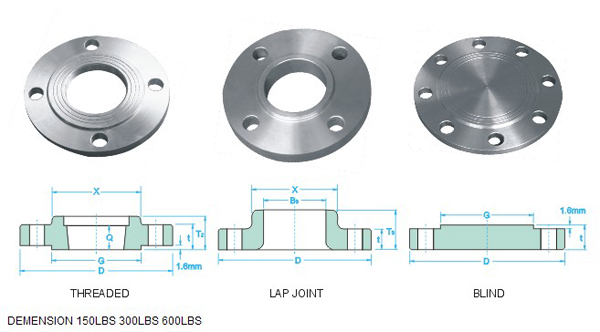

Weld Neck, Slip-On, Socket Weld, Threaded, Lap Joint, Blind Flanges

- Delivery Time:

- 10 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

2.Competitive price

3.Small/OEM order accepted

4.Punctual delivery

5.Excellent service

Product Description Product Name: Weld Neck, Slip-On, Socket Weld, Threaded, Lap Joint, Blind Flanges,Flanges Feature:

Size | 1/2"-36" |

Class | 150LBS,300LBS,600LBS,900LBS,1500LBS,2500LBS,DIN Standard ND-6,10,16,25, 40 Etc |

Stainless Steel | ASTM A182,A240 F304,304L,304H,316,316L,316Ti,310,310S,321,321H,317, 347,347H,904L |

Duplex Steel | ASTM/ASME A/SA 182 F44,F45,F51,F 53,F55,F60,F61 |

Alloy Steel | ASTM/ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

Carbon Steel | ASTM/ASME A/SA 105 ASTM/ASME A350,ASTM A 181 LF 2/A516 Gr.70 A36,A694 F42,F46, 52,F60,F65,F70 |

Standard | ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278,DIN Flange |

Type of Flange | Weld Neck Flange - WNRF |

Production: Cutting: material is cool cut or saw cut. Forging: after heating up, all material blocks are free forged, die forged or ring rolled according to their size. Heat Treatment: We have 6 sets of electric shaft furances, 3 sets of high-temperature, car type electric furnaces, and can do normalizing treatment and drawing temper. Machining: Rough parts are machined by engine lathe and digital lathe according to the size, flange type andtolerance requirement. Drilling: The semi-finished-products are drilled Surface treatment: Die-stamp, wash, paint, oil or galvanize flanges according to the customers' requirement Packing: Pack the flange as requested Packaging & Shipping Flange Package: 1. Industrial Package: Plastic Film+Carton+Wooden Pallet 2. Commercial Package: Plastic Bag/Film+Carton+Wooded Pallet

Production: Cutting: material is cool cut or saw cut. Forging: after heating up, all material blocks are free forged, die forged or ring rolled according to their size. Heat Treatment: We have 6 sets of electric shaft furances, 3 sets of high-temperature, car type electric furnaces, and can do normalizing treatment and drawing temper. Machining: Rough parts are machined by engine lathe and digital lathe according to the size, flange type andtolerance requirement. Drilling: The semi-finished-products are drilled Surface treatment: Die-stamp, wash, paint, oil or galvanize flanges according to the customers' requirement Packing: Pack the flange as requested Packaging & Shipping Flange Package: 1. Industrial Package: Plastic Film+Carton+Wooden Pallet 2. Commercial Package: Plastic Bag/Film+Carton+Wooded Pallet3. As the clients requirements

Company Information Our Product Ranges: Precision Metal Stamping Parts--Hinges, Brackets, Custom Accessories for Auto, Furniture, Construction CNC Machining Parts Castings & Forgings Pipe Fittings, BW Fittings Ventilation parts, Duct Fittings Rubber and Plastic products

Company Information Our Product Ranges: Precision Metal Stamping Parts--Hinges, Brackets, Custom Accessories for Auto, Furniture, Construction CNC Machining Parts Castings & Forgings Pipe Fittings, BW Fittings Ventilation parts, Duct Fittings Rubber and Plastic products Main Business | Stamping, Deep Drawn, Fabrication, Welding, Machining, Castings,Forgings, Rubber & Plastic Parts |

Processed Material | Carbon Steel, Stainless Steel, Aluminum, Alloy steel, Copper, Brass (according to customer's requirement) |

Equipments | Punches: 6.3ton – 400ton Deep Drawing Hydraulic Press: 100ton-315ton Machining Equipments:cutting machine,welding machine, polish machines,milling machine,grinding machine,drilling machine,lathe CNC,etc. Inspection Equipments:material testing machine, metallographic microscope,chemical analyzer,projector etc |

Surface Finish | Powder Coating,Galvanization(hot or cold),Electro-deposition coating,chrome/zinc/nickel plating, polishing, Silkscreen,Heat treatment,black oxide RoHS compliance for export |

Inspection | In-house/third party, all the products are strictly inspected by operator and skilled QC with record put down |

Applied software for specification drawing | Pro/E,Solid Work 2001,Auto CAD,CAXA,UG,CAD/CAM/CAE. |

Feature | High precision and durable, High strength, anti-corrosion, Environmental protection, Heavy-duty |

Apply area | Automotive Industry, Electrical Industry,Building Industry,Furniture Industry,Machine assembly Industry,Computer components Industry,Aircondition industry |

Advantages | 1. tooling, stamping, deep-drawn, machining, welding, surface treatment and assembly, we offer one-stop solution 2. sample making will be started after CAD drawing's approval; production will be started after sample approval; if sample fail in the first time, we will improve and make until your satisfaction. 3. prices are strictly based on your design and requested quantity. 4. Many years experience in metal sheet processing |

FAQ Sample policy: If you want to check sample first, you need pay the sample charge and the charge will be refund to you when the mass order confirmed Price: If you want to know the price, please kindly confirm which product you need or send us your product's picture, so that we can provide you the best price with details Payment Terms: 1. T/T ( with 30% deposit ) , L/C at sight 2. Customers can choose which payment ways that you accept Shipping Terms: 1. Loading Port: TianJin, China 2. Samples Delivery: About 15-30 days after receiving the deposit Mass Production Delivery: General around 25-30 days after sample confirmed Packing Details: 1. Our general packing were carton with pallet 2. According to clients' specific requirements Our advantages: 1. Factory directly supply 2. Many years manufacture experience 3. Competitive and reasonable price 4. OEM service, we can do as your drawings or samples 5. Quality Guarantee 6. Good after-sale service 7. Timely delivery 8. High-tech CNC Machines 9. Independent Engineering Department Send us your enquiry and we guarantee to provide you with the best prices with top quality products and services

FAQ Sample policy: If you want to check sample first, you need pay the sample charge and the charge will be refund to you when the mass order confirmed Price: If you want to know the price, please kindly confirm which product you need or send us your product's picture, so that we can provide you the best price with details Payment Terms: 1. T/T ( with 30% deposit ) , L/C at sight 2. Customers can choose which payment ways that you accept Shipping Terms: 1. Loading Port: TianJin, China 2. Samples Delivery: About 15-30 days after receiving the deposit Mass Production Delivery: General around 25-30 days after sample confirmed Packing Details: 1. Our general packing were carton with pallet 2. According to clients' specific requirements Our advantages: 1. Factory directly supply 2. Many years manufacture experience 3. Competitive and reasonable price 4. OEM service, we can do as your drawings or samples 5. Quality Guarantee 6. Good after-sale service 7. Timely delivery 8. High-tech CNC Machines 9. Independent Engineering Department Send us your enquiry and we guarantee to provide you with the best prices with top quality products and services

Related Keywords