Brand new cooling water tower with high quality

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Glass fiber reinforced plastic cooling tower corrosion resistance, high strength, light weight, small volume, covers an area of less, beautiful and durable, and transportation, installation and maintenance are convenient.Which is extensively used to national economy departments, to air conditioning, refrigeration, air compressor station, heating furnace and the cooling process is especially suitable for cooling water circulation system.

Glass fiber reinforced plastic cooling tower corrosion resistance, high strength, light weight, small volume, covers an area of less, beautiful and durable, and transportation, installation and maintenance are convenient.Which is extensively used to national economy departments, to air conditioning, refrigeration, air compressor station, heating furnace and the cooling process is especially suitable for cooling water circulation system.Circular counterflow FRP cooling tower

Circular counterflow FRP cooling tower the counterflow air heat exchange technology, the packing is made of high quality modified polyvinyl chloride YiBo piece, to spread to drench water area;In spinning cloth water way, achieving a uniform water distribution, enhance the cooling effect.This series of products of our factory has design for local improvement, make it more reliable, durable, easy to assemble.

The main purpose

(1) DBNL3 series low noise type FRP cooling tower, is suitable for the temperature drop 3-8 degrees of ordinary cooling occasions such as air conditioning refrigeration unit.

(2) CDBNL3 series low noise type FRP cooling tower - applies to the more strict noise in hotels, hospitals, public buildings and residential area close to occasions.

(3) GBNL3 series in high temperature industrial FRP cooling tower, is suitable for the temperature drop 10 to 25 degrees of industrial circulating cooling water system. Types of

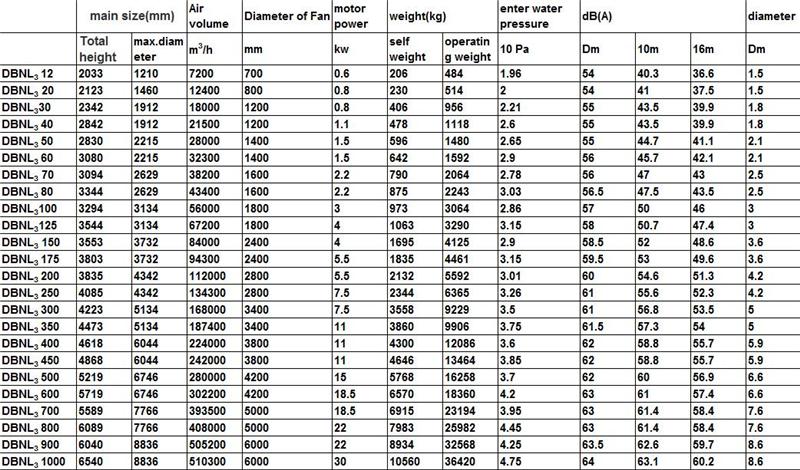

Circular counterflow FRP cooling tower has three series: DBNL3, CDBNL3, GBNL3 1, the design parameters:

1) standard conditions: water temperature t1 = 37 °C, the temperature t2 = 32 °C, design wet-bulb tau = 28 °C, the water temperature Δ t = 5 °C, cold high t2 - tau = 5 °C

T1 = 2) medium temperature conditions: water temperature 43 °C, the temperature t2 = 33 °C, design wet-bulb tau = 28 °C, the water temperature Δ t = 10 °C cold high t2 - tau = 6 °C

T1 = 3) high temperature working condition, water temperature 60 °C, the temperature t2 = 35 °C, design wet-bulb tau = 28 °C, the water temperature Δ t = 25 °C cold high t2 - tau = 8 °C

Water Q 2, selection guidelines, inlet water temperature of t1, t2 and water temperature design wet-bulb tau, then according to thermal performance curve model.See table 1 and table 2 thermal performance curves.Of curve table outside the condition, can undertake thermodynamic calculation, the packing volume dispersion coefficient beta * argument is as follows:

1.2 times the nominal flow: beta * argument = 1.0 times the nominal flow rate: 18600 beta * argument = 0.8 times the nominal flow rate: 17800 beta * argument = 17000

3, press the tower body weight operation half water depth calculation, if calculated by filled with water should be multiplied by 1.5.

4, this series of cooling tower used in the most of the average temperature is not lower than - 10 °C, the temperature too low users should request to prevent freezing, in order to configure drench water diversion ring, don't make the water flow to the stomach.Winter intermittent operation process, can be inside the water tank, electric heat pipe.This series of cooling tower used in the most of the average temperature is not lower than - 10 °C, the temperature too low users should request to prevent freezing, in order to configure drench water diversion ring, don't make the water flow to the stomach.Winter intermittent operation process, can be inside the water tank, electric heat pipe.

5, circulating water turbidity is not more than 50 mg/l, in the short term is not more than 100 mg/l, unfavorable oil content and mechanical impurities, algae and water quality stability measures when necessary.

6, suitable water temperature less than 60 °C, such as more than when ordering, our factory is addressed from the selection.For flame retardant cooling tower, please when ordering, our factory can meet the requirements

7, cloth pipes in nominal flow hole, such as the actual flow differ with nominal flow plus or minus 15%, when you place an order should be stated.

8, pressure pipe water pressure is about 2-5 m water column, the design don't pressure is too high, otherwise it will produce water phenomenon.

9, motor, fan equipped to supply to our factory to send installation or technical guidance, the extra expenses.

10, when users need to direct water cooling tower under the tower body, need to install the automatic feed pipe ", "rapid feed pipe" "tubes" overflow ", "need to be specifically when you order it. Structural features

: 1) the tower body lines is reasonable, the air flow is smooth, excellent material, surface gel coating contains anti-ultraviolet radiation dose.Ageing resistance, high strength, light weight, corrosion resistance.Under the tower body according to the order, can be equipped with water, sewage, automatic feed pipe, can directly absorbent, save cooling pool, equipped with anti noise silencer pad above, effectively reduce the drip. (2) packing: using modified polyvinyl chloride (PVC) wave plate, increased lateral convex rib, water redistribution ability is strong, small resistance, good thermal performance, high temperature resistant, low temperature of 70 degrees to 50 degrees, good flame retardancy.

(3) spin cloth water, and water pipe, is equipped with stainless steel ball bearing, flexible and reliable operation, low water head, uniform water distribution, aluminum alloy or fiberglass cloth pipe, pipe installed on the water board, to overcome the phenomenon of floating water.

Fan: (4) by the tsinghua university and majored in mechanical engineering according to series of parameter design of the cooling tower fan, low noise, high efficiency of the aluminum alloy plate airfoil or GRP blades, low noise, high efficiency.

(5) : motor by the tsinghua university electrical engineering department on the basis of Y series installation size, designed for cooling tower, sealed a good waterproof performance, low noise and energy saving motor of high temperature resistance, high efficiency, low noise.

Speed reducer (6) : using the polyester fiber reinforced neoprene belt transmission, high temperature resistant, high efficiency, meet water will not stretch, overcome the skid phenomenon, the noise is very small.

(7) acoustic facilities: low noise type cooling tower increased with outside air inlet sound-absorbing material shielding, and in the two fitted with sound absorption grating, in order to achieve maximum noise reduction effect.Outlet installed in the tower body with shielding and absorption material trumpet sound absorption grid, reduce the noise of the fan and motor coming.

(8) into the wind window, is equipped with glass fiber reinforced plastic blade, reduce the wave of water, air flow resistance is small, especially suitable for northern area and require the use of cooling tower unit all year round.

(9) support: all blower, packing, into the wind window, the place such as the tower body is fabricated steel stents, galvanized or paint anticorrosion.Fasteners are made of galvanized or stainless steel bolts.

Installation, debugging and use information

1, the foundation drawing and installation dimensions for installation in this manual as a reference.

Small counterflow tower in and out of the direction of the pipe can be arbitrarily selected in a horizontal position, but not crash.

There is, the load shall be 25% of the operation, to the rest of the outer rectangle based on average by 75%, as in the roof installation load caused by the additional pressure should be taken into account.

2, the joint of the cooling tower and in and out of the pipe should be set, to prevent too much weight on the tower wall.

3, fan blades should be adjusted before installation and use, keep perspective.Method for near 150 mm between leaf, respectively for both before and after each blade edge as a sign, and then by both before and after stent bottom chord of each blade edge distance, to calculate the difference of each leaf margin before and after this several times by adjusting the elevation difference reached a consensus to qualified.

After 4, electrical wiring to seal junction box, and pay attention to the current test values less than airborne rated current.

5, when start the cooling tower must first after open water pump open fan, does not allow in the absence of rain water make the fan operation, the fan can be short-term low speed reverse away the ice.

6, deceleration machine before use should note oil, 50, can adopt anti-wear gear oil or oil lubrication, the first 100-300 hours operation should change new oil, operating 3000-5000 hours after every oil change at a time.Oil level should be moderate, oil standard should be convenient for observation.

7, cooling tower operation, personnel management, often pay attention to the change of current, temperature, the motor, speed reducer, the place such as the water should be check regularly.

Company Information

Our Services

Our Services  FAQ Q: Are you a trading company or a manufacture factory? A: Our factory is one of the biggest FRP products, FRP machines manufacturer in China Q: Can your factory customize the machine for clients ? A: Yes, we can. Q: What is your payment terms ? A: Normally,50% as the deposit first by T/T, the rest 50% will be paid before shipping by T/T. Q: How about after-sales service ? A: 1 year free warranty, Lifetime technical service support. Q: How can I install the production line and get a commissioning ? A: We may send our engineer for installation and commissioning, but relevant cost will be paid by you. Q:Have you some videos where we can see the line producing? A: Yes, we can provide some videos. How is the packing? Steel frame for plywood Box Package with steel belt. save space as much as possible for container loading. Any enquiry please feel free contact us. TEL: +86-311-89805927 MOB:+86 15103313719 QQ: 2826281089 Whatsapp: 15103313719 Add: B-1505,white commercial plaza.No.105, Huaian East Road, Yuhua District, Shijiazhuang,Hebei,China.

FAQ Q: Are you a trading company or a manufacture factory? A: Our factory is one of the biggest FRP products, FRP machines manufacturer in China Q: Can your factory customize the machine for clients ? A: Yes, we can. Q: What is your payment terms ? A: Normally,50% as the deposit first by T/T, the rest 50% will be paid before shipping by T/T. Q: How about after-sales service ? A: 1 year free warranty, Lifetime technical service support. Q: How can I install the production line and get a commissioning ? A: We may send our engineer for installation and commissioning, but relevant cost will be paid by you. Q:Have you some videos where we can see the line producing? A: Yes, we can provide some videos. How is the packing? Steel frame for plywood Box Package with steel belt. save space as much as possible for container loading. Any enquiry please feel free contact us. TEL: +86-311-89805927 MOB:+86 15103313719 QQ: 2826281089 Whatsapp: 15103313719 Add: B-1505,white commercial plaza.No.105, Huaian East Road, Yuhua District, Shijiazhuang,Hebei,China.Profiles machine

welcome to visit

welcome to visit  Packaging & Shipping

Packaging & Shipping

Related Keywords

Related Keywords