High Capacity Centrifugal Sand Dredge Slurry Pump

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

High Capacity Centrifugal Sand Dredge Slurry Pump The Depon® slurry pump is the world's standard for the most difficult mill duties. A wide variety of impellers and shaft seals provide a prefect fit for a wide range applications. The Depon® slurry pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. Product Description  High Head 100meters Slurry Pump for Mine Made in China

High Head 100meters Slurry Pump for Mine Made in China  Applications of Slurry Pump

Applications of Slurry Pump

Features of Slurry Pump

Features of Slurry Pump

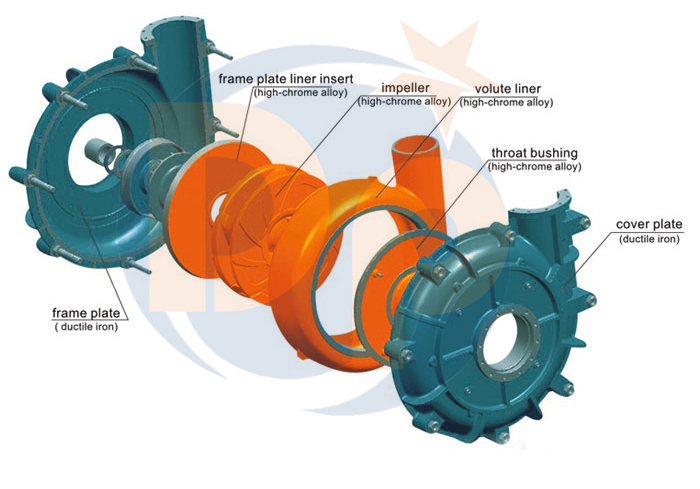

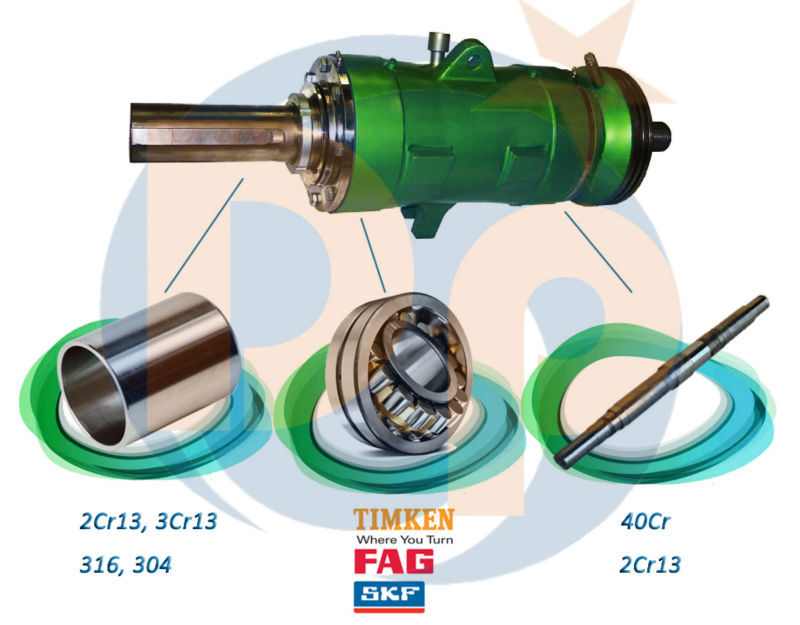

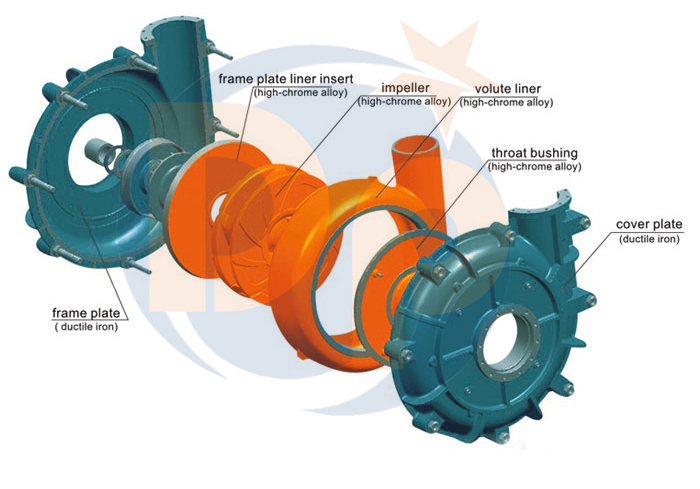

· Bearing assembly- large diameter shaft with short overhang contributes to long bearing life. · Liners – easily replaceable liners are bolted, not glued to the casing for positive maintenance. · Casing – Casing halves of cast or ductile iron provide high operating pressure capabilities. · Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. · Throatbush – wear is reduced and maintenance simplified by the use of tapered. Slurry Pump

Slurry Pump

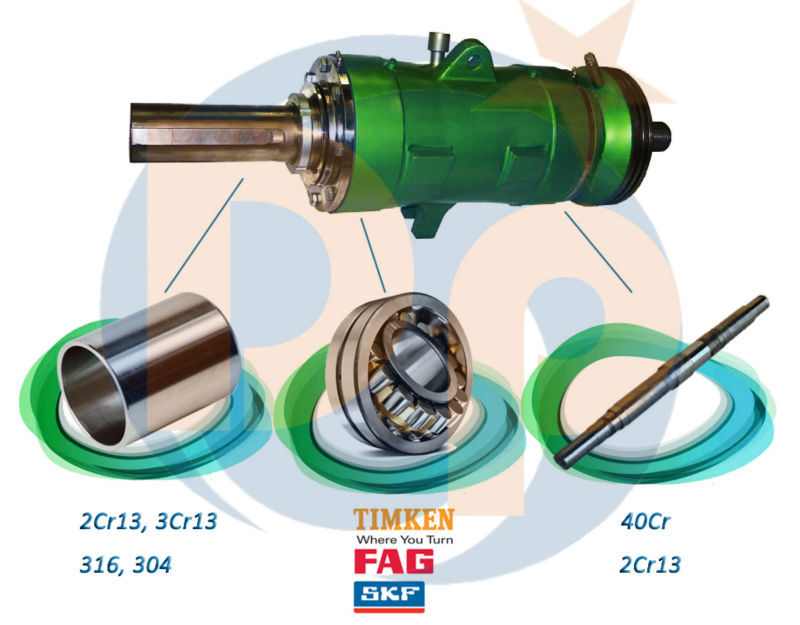

Bearing Assembly

Bearing Assembly  Impeller

Impeller  Spare parts of AH pumps

Spare parts of AH pumps

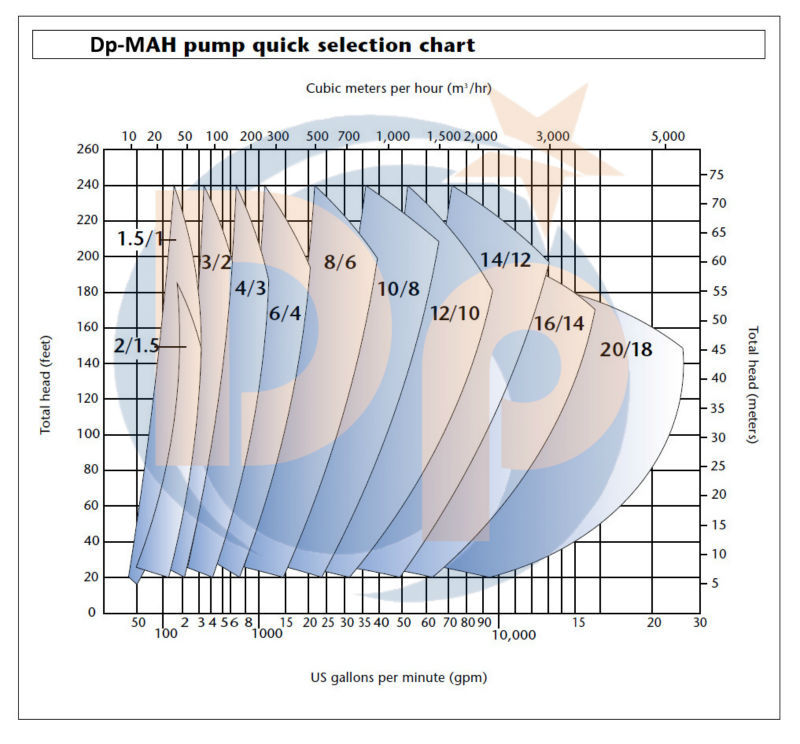

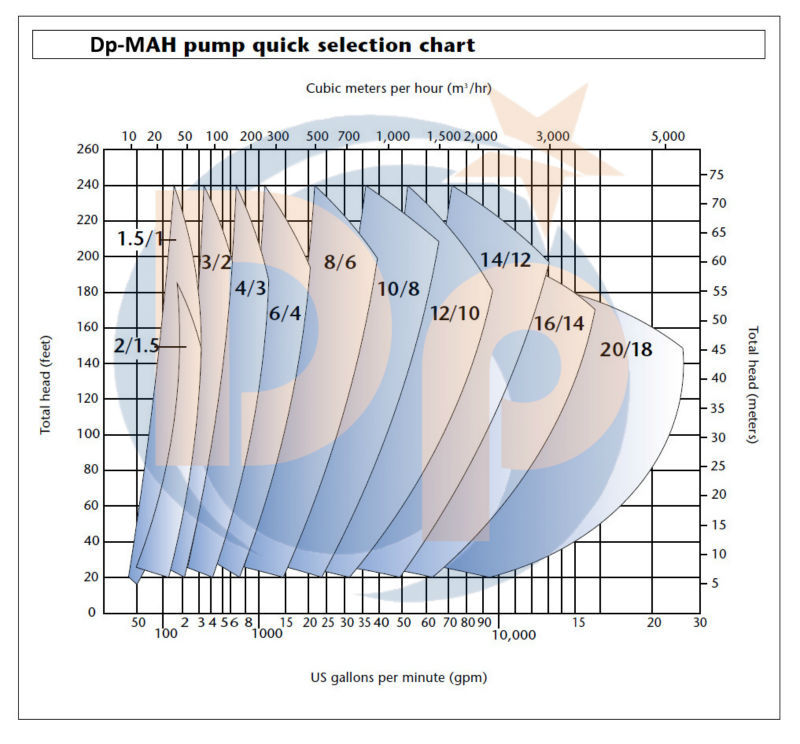

Technical Data of Slurry Pump

Technical Data of Slurry Pump

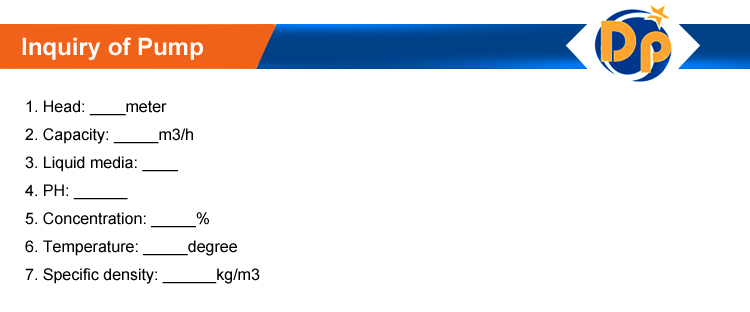

Inquiry of Pump  Contact Us

Contact Us

High Head 100meters Slurry Pump for Mine Made in China

High Head 100meters Slurry Pump for Mine Made in China  Applications of Slurry Pump

Applications of Slurry Pump

Features of Slurry Pump

Features of Slurry Pump · Bearing assembly- large diameter shaft with short overhang contributes to long bearing life. · Liners – easily replaceable liners are bolted, not glued to the casing for positive maintenance. · Casing – Casing halves of cast or ductile iron provide high operating pressure capabilities. · Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. · Throatbush – wear is reduced and maintenance simplified by the use of tapered.

Slurry Pump

Slurry Pump  Bearing Assembly

Bearing Assembly  Impeller

Impeller  Spare parts of AH pumps

Spare parts of AH pumps

Technical Data of Slurry Pump

Technical Data of Slurry Pump | Type | Max. power | Capacity | Head | Speed | Max. Eff | NPSH | IMPELLER | Max. particle size | Weight (KG) | ||

| Quantity of vanes | Diameter (mm) | ||||||||||

| kw | (m³/h) | (l/s) | (m) | (r/min) | % | (m) | mm | ||||

| DAH1.5/1 | 15 | 12-28 | 3.5-8 | 6-65 | 1200-3800 | 40 | 2-4 | 5 | 150 | 14 | 90 |

| DAH2/1.5 | 15 | 32-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 185 | 19 | 105 |

| DAH3/2 | 30 | 39-86 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 5 | 215 | 25 | 190 |

| DAH4/3 | 30 | 86-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 5 | 245 | 28 | 260 |

| DAH4/3 | 60 | 86-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 5 | 245 | 28 | 360 |

| DAH6/4 | 60 | 162-360 | 45-100 | 12-56 | 800-1500 | 68 | 5-8 | 5 | 365 | 44 | 625 |

| DAH6/4 | 120 | 162-360 | 45-100 | 12-56 | 800-1500 | 68 | 5-8 | 5 | 365 | 44 | 728 |

| DAH8/6 | 120 | 360-830 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 5 | 510 | 63 | 1470 |

| DAH10/8 | 260 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 5 | 685 | 76 | 3800 |

| DAH12/10 | 560 | 936-1980 | 260-550 | 7-68 | 400-750 | 82 | 1-5 | 5 | 760 | 86 | 4320 |

| DAH14/12 | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 5 | 965 | 90 | 6400 |

Contact Us

Contact Us

Related Keywords

Related Keywords