Electric Motor Drive Centrifugal Slurry Pump

- Delivery Time:

- 10 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

2.Discharge Size: 25mm-450mm

3.Capacity: to 3400 m3/hr

4.Head: to 120m

5.Certificate: ISO,CE,SGS

AM centrifugal slurry pumps are mainly used to pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and etc.

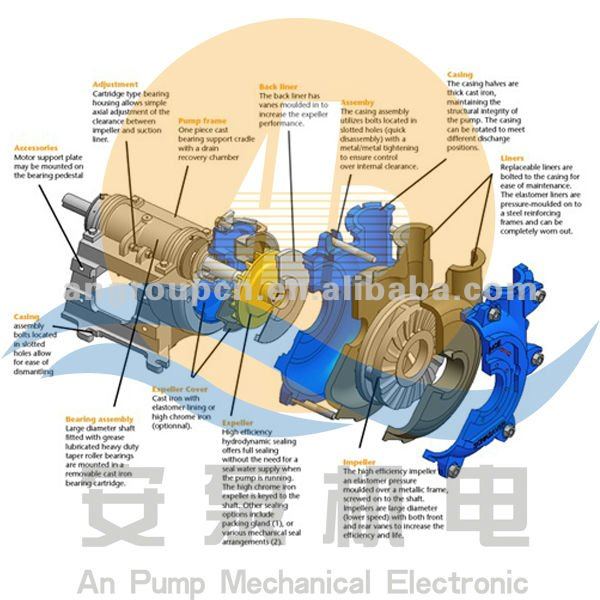

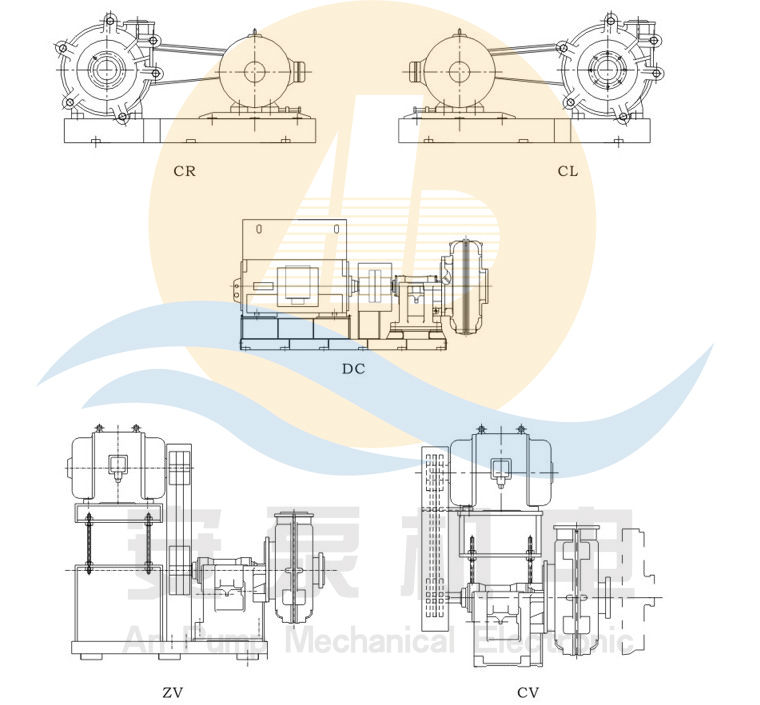

Electric Motor Drive Centrifugal Slurry Pump Detailed specification 1. Horizontal, cantilevered, centrifugal, single stage slurry pump 2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 3. Wear resistant and anti-abrasion wet parts: A05, A07, A33, A49 and rubber etc. They are completely interchangeable with each other 4. Easily replaceable liners: Liners are bolted to the casing. 5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 6 Discharge direction can be positioned at intervals of 45 degrees. 7. Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8. Sealing type: pcking seal,impeller sealing and mechanical seal. 9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments. 10.Certificate: ISO, CE. 11. Welcome OEM. Electric Motor Drive Centrifugal Slurry Pump structure drawing

Electric Motor Drive Centrifugal Slurry Pump Parameters

Electric Motor Drive Centrifugal Slurry Pump Parameters Model | Flow | Head | Frame | Max Power | Eff | Max Particle Size | Material |

AMB 1.5x1 | 3 - 40 | 5 - 68 | B | 15 | 20 - 40 | 20 | High Cr Alloy/Rubber |

AMB 2x1.5 | 7 - 87 | 8 - 63 | B | 15 | 20 - 45 | 19 | High Cr Alloy/Rubber |

AMC 3x2 | 21 - 139 | 10 - 64 | C | 30 | 30 - 58 | 25 | High Cr Alloy/Rubber |

AMC 4x3 | 14 - 201 | 7 - 53 | C | 30 | 30 - 71 | 28 | High Cr Alloy/Rubber |

AMD 4x3 | 14 - 201 | 7 - 53 | D | 60 | 30 - 71 | 28 | High Cr Alloy/Rubber |

AMD 6x4 | 25 - 504 | 11 - 62 | D | 60 | 30 - 68 | 44 | High Cr Alloy/Rubber |

AME 6x4 | 25 - 504 | 11 - 62 | E | 120 | 30 - 68 | 44 | High Cr Alloy/Rubber |

AME 8x6 | 43 - 900 | 8 - 63 | F | 120 | 20 - 72 | 63 | High Cr Alloy/Rubber |

AMST 10x8 | 220 - 1800 | 9 -65 | ST | 560 | 21 - 71 | 76 | High Cr Alloy/Rubber |

AMST 12x 10 | 35 - 2088 | 7 - 67 | ST | 560 | 20 - 80 | 86 | High Cr Alloy |

AMST 14x12 | 40 - 3564 | 11 - 65 | ST | 560 | 40 -75 | 90 | High Cr Alloy |

AMTU 16x14 | 324 -4700 | 10 - 65 | TU | 1200 | 50 - 82 | 123 | High Cr Alloy |

AMTU 20x18 | 570 - 6700 | 11 - 59 | TU | 1200 | 40 - 85 | 135 | High Cr Alloy |

I think you will find that making a partner of An Pump, will be your best decision for getting true value in solving your slurry pump problems. Product pictures:

Electric Motor Drive Centrifugal Slurry Pump Application

Electric Motor Drive Centrifugal Slurry Pump Application  Our Services Our Services 1. Offer Large capacity pump solutions

Our Services Our Services 1. Offer Large capacity pump solutions2. Selection

3. OEM available

4. ODM available

5. Design

6. Installation

7. Maintenance

Company Information

Company Information  Our Main Products

Our Main Products  Some clients visit our factory

Some clients visit our factory  Contact Us

Contact Us  Learn more , please contact us directly. Mandy Wang

Learn more , please contact us directly. Mandy WangInternational Dept. Shijiazhuang An pump Machinery Co.,Ltd Web:www.angroupcn.com Email:coco(@)angroupcn.com Tel:86-311-89940549 Fax:86-311-86271170 International calls:86 15032857866 WhatsApp:008613731071183 Skype:mandy.anpump

Related Keywords