Heavy Duty Metal Liner Sump Pump For Mineral Processing

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Heavy Duty Metal Liner Sump Pump For Mineral Processing  Product Description Description - Heavy Duty Metal Liner Sump Pump For Mineral Processing

Product Description Description - Heavy Duty Metal Liner Sump Pump For Mineral Processing

BP and BPR pumps are vertical, centrifugal slurry pumps submerged in sump to work. They are designed for delivering abrasive, large particle and high density slurry. These pumps have no need of any shaft seal and sealing water. They can also be operated normally for insufficient suction duties. Application- Heavy Duty Metal Liner Sump Pump For Mineral Processing The rugged BP,BPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in: • Minerals processing

Application- Heavy Duty Metal Liner Sump Pump For Mineral Processing The rugged BP,BPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in: • Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel and almost every other tank, pit or hole-in-the-ground slurry handling situation. The BP/BPR design with either hard metal (BP) or elastomer covered (BPR) components makes it ideal for: • Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Continuous or “snore” operation

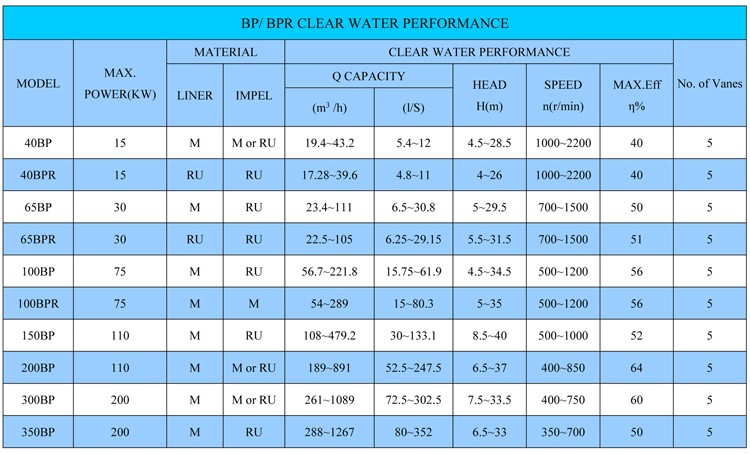

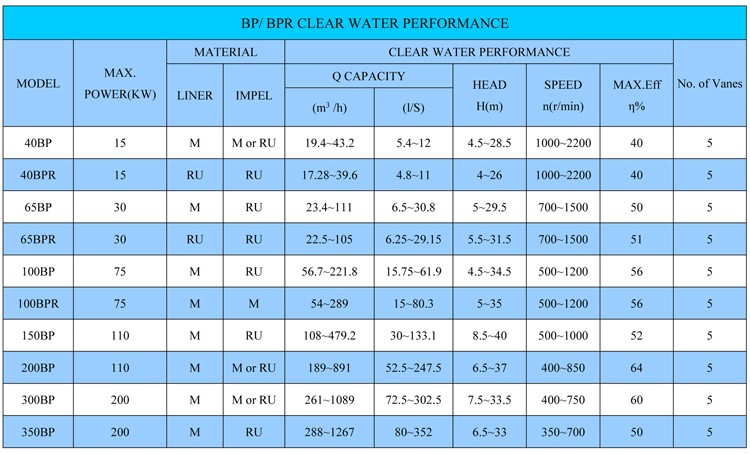

• Heavy duties demanding cantilever shafts Performance Chart- Heavy Duty Metal Liner Sump Pump For Mineral Processing

Performance Chart- Heavy Duty Metal Liner Sump Pump For Mineral Processing

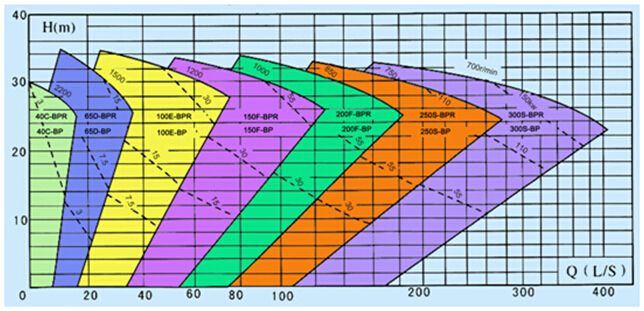

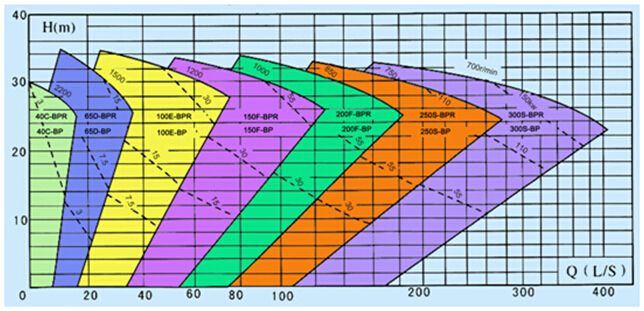

Performance curve - Heavy duty metal liner Sump Pump Vertical Slurry Pump

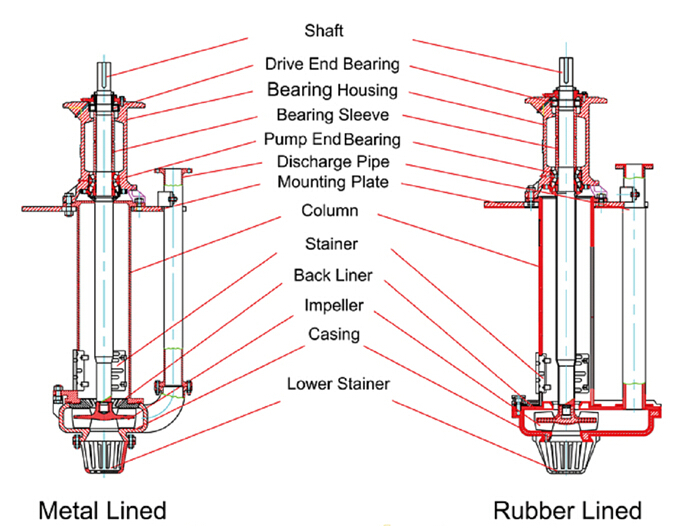

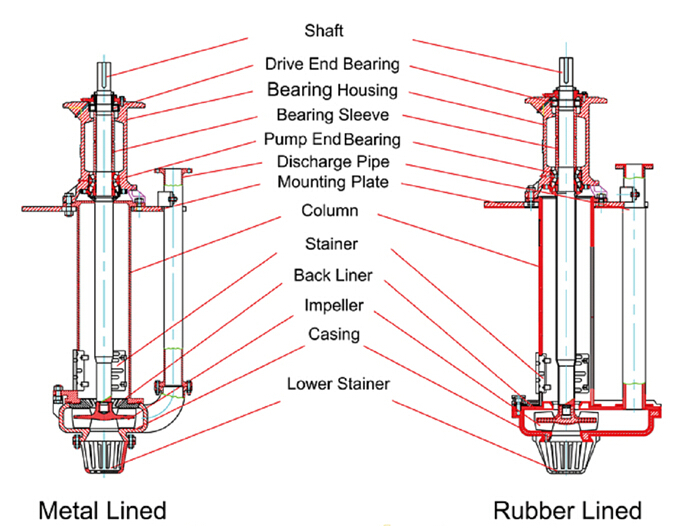

Structure - Heavy Duty Metal Liner Sump Pump For Mineral Processing

Structure - Heavy Duty Metal Liner Sump Pump For Mineral Processing

Packing - Heavy Duty Metal Liner Sump Pump For Mineral Processing

Packing - Heavy Duty Metal Liner Sump Pump For Mineral Processing

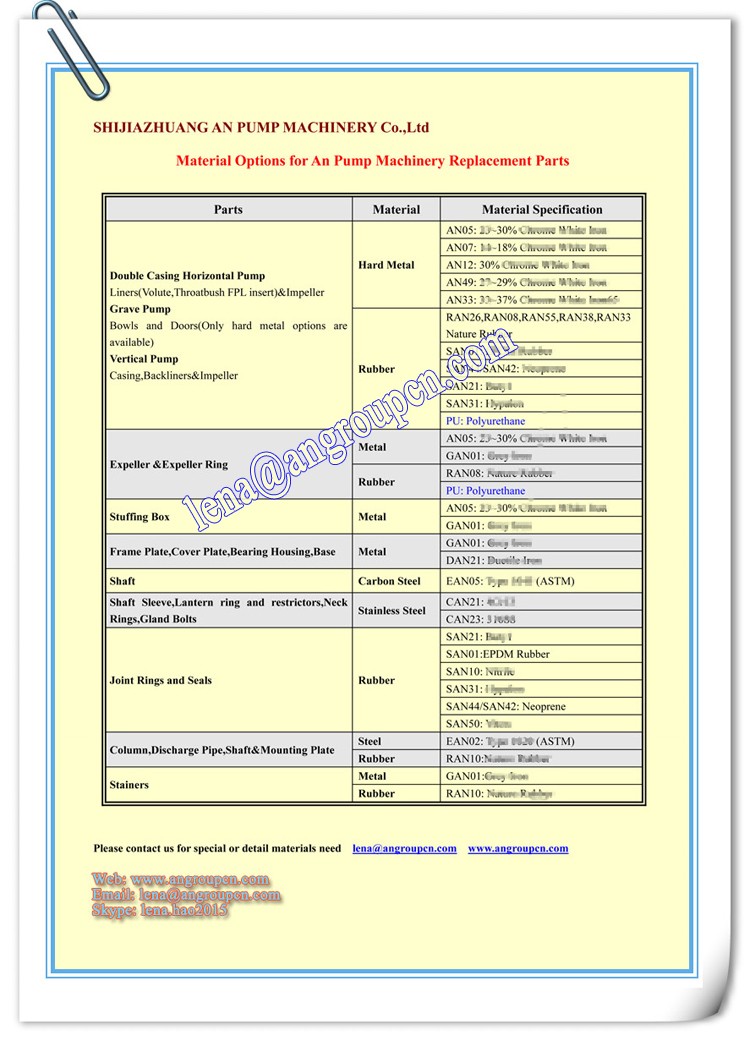

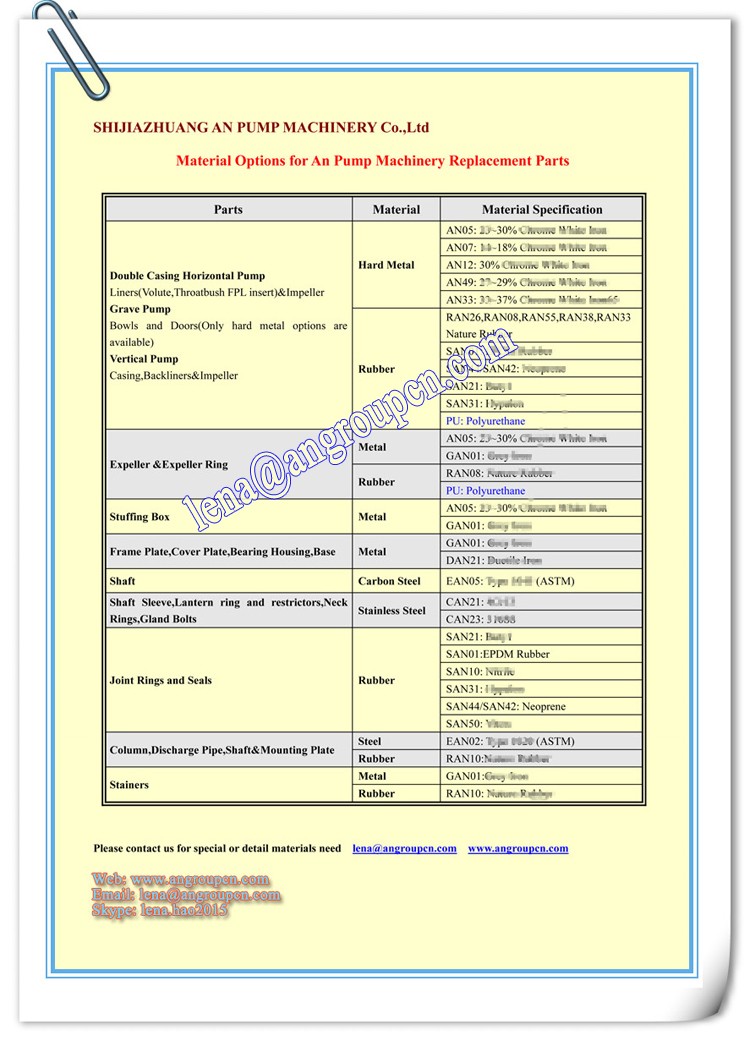

Materials- Heavy Duty Metal Liner Sump Pump For Mineral Processing

Materials- Heavy Duty Metal Liner Sump Pump For Mineral Processing

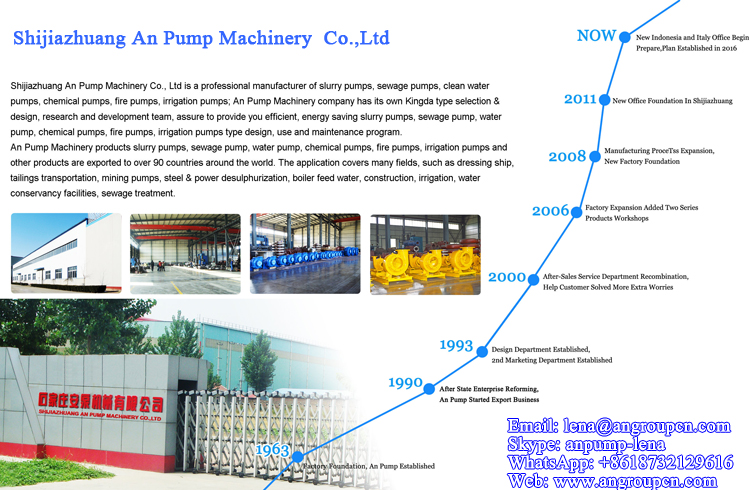

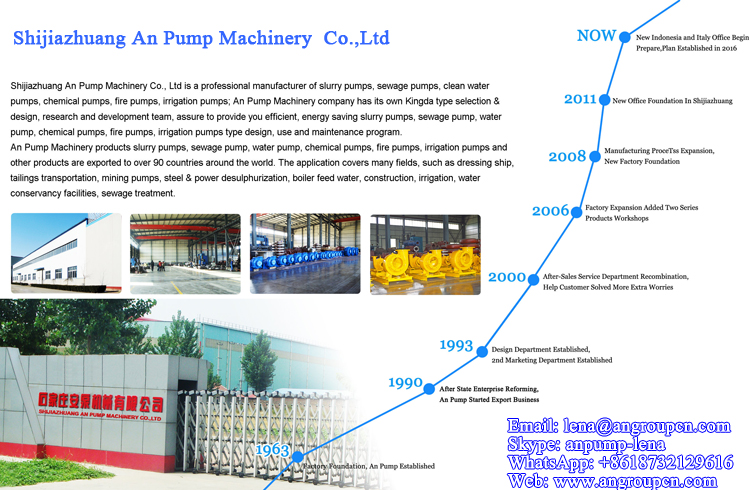

Company Information

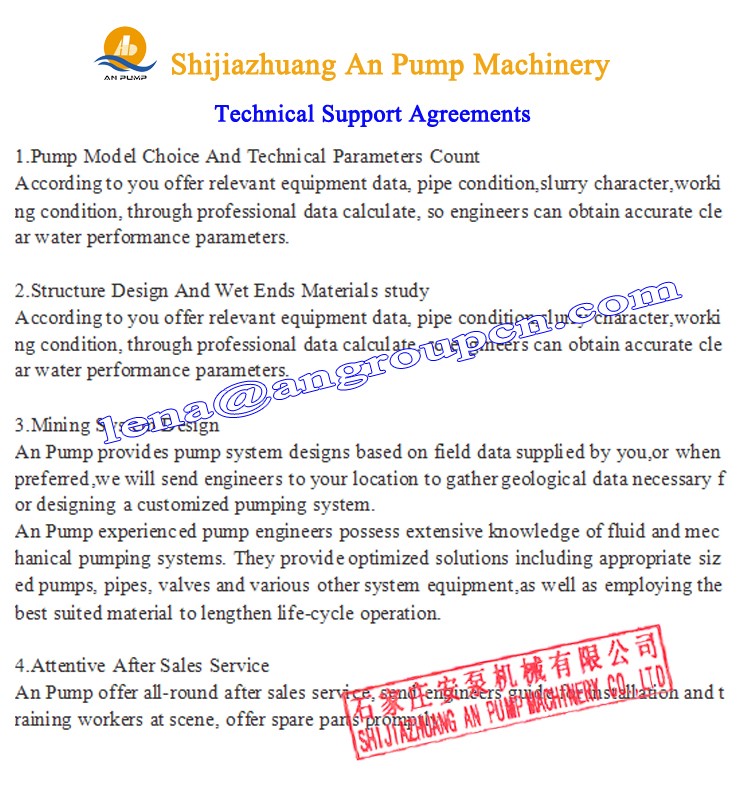

Our Services

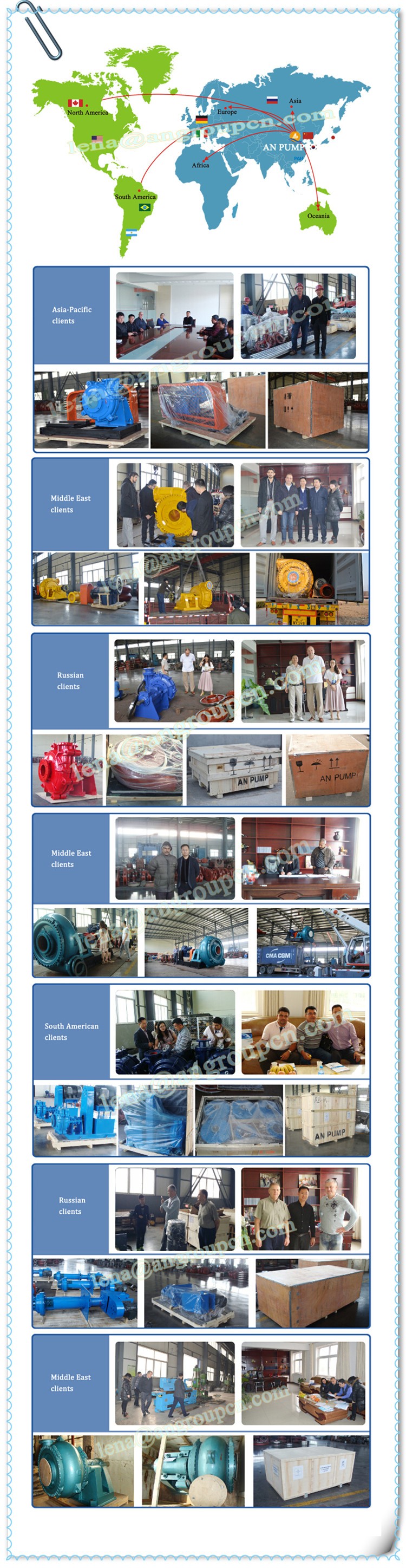

Our Services  Our Advantages You will obtain products and service advantages *About 30 years Design, produce and service experience. *Price is suitable. We are directly factory, own finished foundry model, cost only including original materials fee, machinery fee, worker fee. *Quality, our materials used high chrome, reached above 27%, 28%, wear resistant and corrosion resistant , pump use life longer. High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate *After sale service, we can offer 2 years quality guarantee, also have a very strong technical support department and special after sale service department. When you have any need future, we can sent you professional technical man to Russian help you. We also have one of group high quality technicians who can help you solve any question during the process *When received your order, we have very professional manufacture process and supervision process. For you, i also will to plant supervise manufacture and take photo for you per day in person. So can keep you do not worry. *After finish manufacture, we will test each pump. take a video and make a testing report for you. If available, you also can to our factory to supervise testing in person. *Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon *Rich export Experience. we had export USA, Germany,Canada , Australian and so on developed country and South Africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high reputation at home and abroad. Certificate - Heavy duty metal liner Sump Pump Vertical Slurry Pump

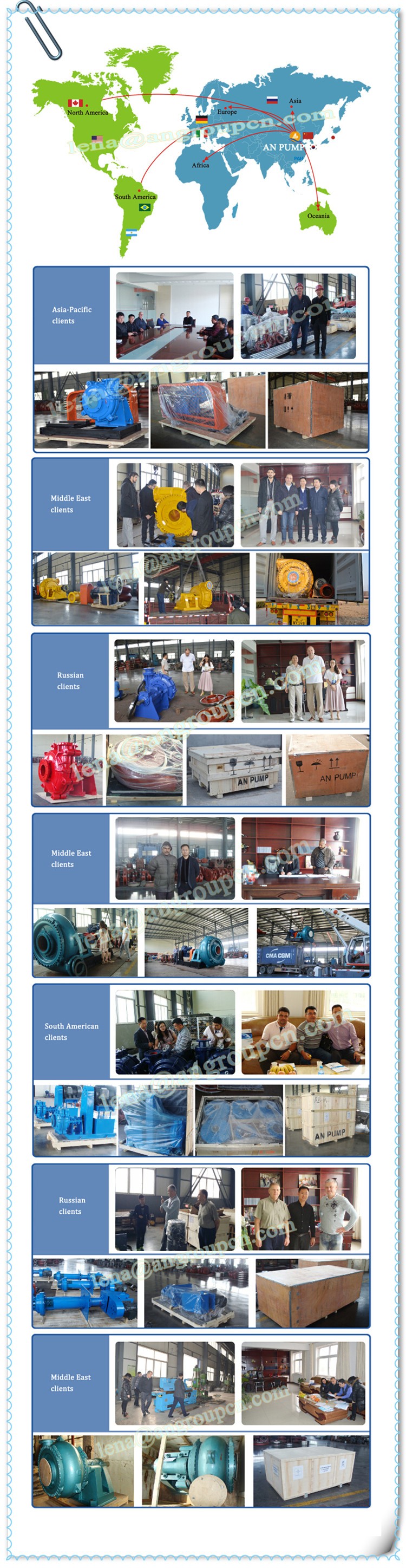

Our Advantages You will obtain products and service advantages *About 30 years Design, produce and service experience. *Price is suitable. We are directly factory, own finished foundry model, cost only including original materials fee, machinery fee, worker fee. *Quality, our materials used high chrome, reached above 27%, 28%, wear resistant and corrosion resistant , pump use life longer. High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate *After sale service, we can offer 2 years quality guarantee, also have a very strong technical support department and special after sale service department. When you have any need future, we can sent you professional technical man to Russian help you. We also have one of group high quality technicians who can help you solve any question during the process *When received your order, we have very professional manufacture process and supervision process. For you, i also will to plant supervise manufacture and take photo for you per day in person. So can keep you do not worry. *After finish manufacture, we will test each pump. take a video and make a testing report for you. If available, you also can to our factory to supervise testing in person. *Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon *Rich export Experience. we had export USA, Germany,Canada , Australian and so on developed country and South Africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high reputation at home and abroad. Certificate - Heavy duty metal liner Sump Pump Vertical Slurry Pump  Reliable Experience

Reliable Experience  Our Team

Our Team  Welcome Contact Us Lena Hao

Welcome Contact Us Lena Hao

Internation Trade Manager WhasApp:+8618732129616

Skype:anpump-lena

Email:lena(at)angroupcn.com

Web:www.angroupcn.com

Product Description Description - Heavy Duty Metal Liner Sump Pump For Mineral Processing

Product Description Description - Heavy Duty Metal Liner Sump Pump For Mineral Processing BP and BPR pumps are vertical, centrifugal slurry pumps submerged in sump to work. They are designed for delivering abrasive, large particle and high density slurry. These pumps have no need of any shaft seal and sealing water. They can also be operated normally for insufficient suction duties.

Application- Heavy Duty Metal Liner Sump Pump For Mineral Processing The rugged BP,BPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in: • Minerals processing

Application- Heavy Duty Metal Liner Sump Pump For Mineral Processing The rugged BP,BPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in: • Minerals processing• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel and almost every other tank, pit or hole-in-the-ground slurry handling situation. The BP/BPR design with either hard metal (BP) or elastomer covered (BPR) components makes it ideal for: • Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Continuous or “snore” operation

• Heavy duties demanding cantilever shafts

Performance Chart- Heavy Duty Metal Liner Sump Pump For Mineral Processing

Performance Chart- Heavy Duty Metal Liner Sump Pump For Mineral Processing

Performance curve - Heavy duty metal liner Sump Pump Vertical Slurry Pump

Structure - Heavy Duty Metal Liner Sump Pump For Mineral Processing

Structure - Heavy Duty Metal Liner Sump Pump For Mineral Processing  Packing - Heavy Duty Metal Liner Sump Pump For Mineral Processing

Packing - Heavy Duty Metal Liner Sump Pump For Mineral Processing  Materials- Heavy Duty Metal Liner Sump Pump For Mineral Processing

Materials- Heavy Duty Metal Liner Sump Pump For Mineral Processing

Company Information

Our Services

Our Services  Our Advantages You will obtain products and service advantages *About 30 years Design, produce and service experience. *Price is suitable. We are directly factory, own finished foundry model, cost only including original materials fee, machinery fee, worker fee. *Quality, our materials used high chrome, reached above 27%, 28%, wear resistant and corrosion resistant , pump use life longer. High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate *After sale service, we can offer 2 years quality guarantee, also have a very strong technical support department and special after sale service department. When you have any need future, we can sent you professional technical man to Russian help you. We also have one of group high quality technicians who can help you solve any question during the process *When received your order, we have very professional manufacture process and supervision process. For you, i also will to plant supervise manufacture and take photo for you per day in person. So can keep you do not worry. *After finish manufacture, we will test each pump. take a video and make a testing report for you. If available, you also can to our factory to supervise testing in person. *Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon *Rich export Experience. we had export USA, Germany,Canada , Australian and so on developed country and South Africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high reputation at home and abroad. Certificate - Heavy duty metal liner Sump Pump Vertical Slurry Pump

Our Advantages You will obtain products and service advantages *About 30 years Design, produce and service experience. *Price is suitable. We are directly factory, own finished foundry model, cost only including original materials fee, machinery fee, worker fee. *Quality, our materials used high chrome, reached above 27%, 28%, wear resistant and corrosion resistant , pump use life longer. High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate *After sale service, we can offer 2 years quality guarantee, also have a very strong technical support department and special after sale service department. When you have any need future, we can sent you professional technical man to Russian help you. We also have one of group high quality technicians who can help you solve any question during the process *When received your order, we have very professional manufacture process and supervision process. For you, i also will to plant supervise manufacture and take photo for you per day in person. So can keep you do not worry. *After finish manufacture, we will test each pump. take a video and make a testing report for you. If available, you also can to our factory to supervise testing in person. *Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon *Rich export Experience. we had export USA, Germany,Canada , Australian and so on developed country and South Africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high reputation at home and abroad. Certificate - Heavy duty metal liner Sump Pump Vertical Slurry Pump  Reliable Experience

Reliable Experience  Our Team

Our Team  Welcome Contact Us Lena Hao

Welcome Contact Us Lena HaoInternation Trade Manager WhasApp:+8618732129616

Skype:anpump-lena

Email:lena(at)angroupcn.com

Web:www.angroupcn.com

Related Keywords

Related Keywords