electric motor large capacity submersible sand pump

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

electric motor large capacity submersible sand pump Pump Application  Applications of large capacity submersible pump The rugged BP,BPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

Applications of large capacity submersible pump The rugged BP,BPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

• Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel and almost every other tank, pit or hole-in-the-ground slurry handling situation.

The BP/BPR design with either hard metal (BP) or elastomer covered (BPR) components makes it ideal for:

• Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Continuous or “snore” operation

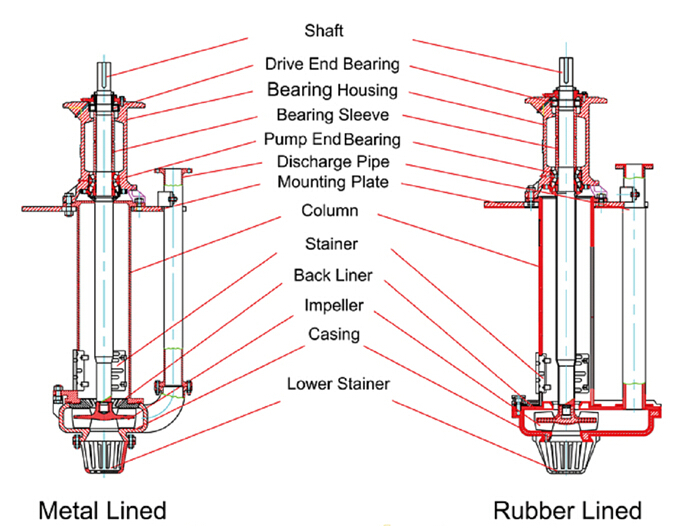

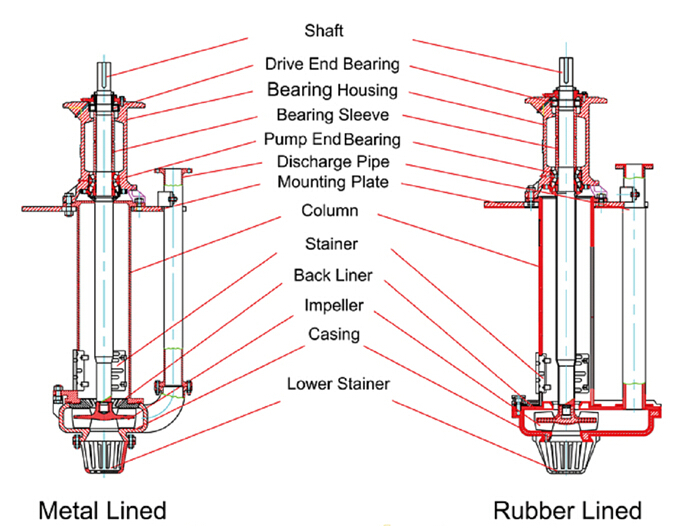

• Heavy duties demanding cantilever shafts Pump Description Feature of large capacity submersible pump Wetted components are available in a wide range of alloys and elastomers, from which An Pump Machinery selects the optimum combination of materials for maximum resistance to wear in virtually any industrial application, including those demanding both abrasion and corrosion resistance and where larger particles or high density slurries are encountered. • Abrasion resistant high Cr alloy.

• Abrasion/corrosion-resistant alloy.

• Corrosion-resistant stainless steels. • Natural and synthetic elastomers. No submerged bearing failures The robust cantilever shaft avoids the need for lower submerged bearings - which are often the source of premature bearing failure. • Heavy duty roller bearings, above mountingplate. • No submerged bearings.

No submerged bearing failures The robust cantilever shaft avoids the need for lower submerged bearings - which are often the source of premature bearing failure. • Heavy duty roller bearings, above mountingplate. • No submerged bearings.

• Labyrinth/flinger bearing protection.

• Rigid, large diameter shaft. No shaft sealing problems The vertical cantilever design requires no shaft seal. No priming required The top and bottom inlet design is ideally suited for “snore” conditions. Less risk of blocking The screened inlets and large impeller passages reduce the risk of blockages. Zero ancillary water costs The vertical cantilever design with no gland or submerged bearings avoids the need for expensive gland or bearing flushing water. Pump Performance Specifications of large capacity submersible pump

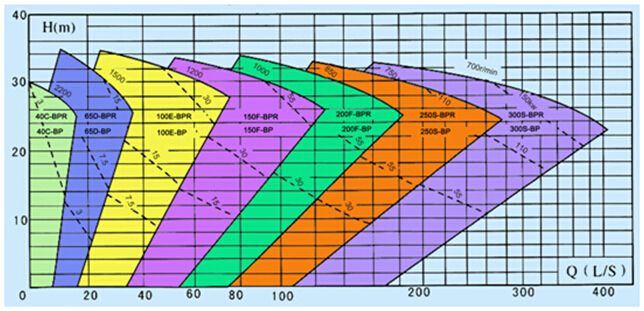

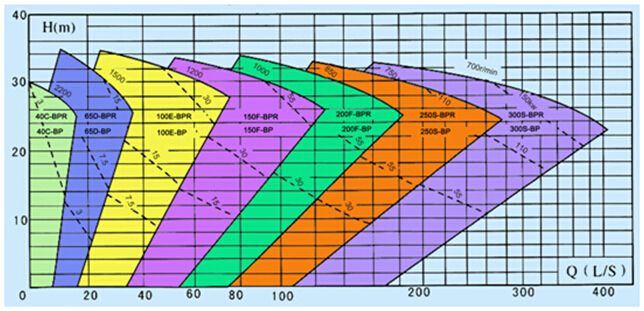

Pump Performance Specifications of large capacity submersible pump

Performance curve of large capacity submersible pump  FAQ 1. Q: Are you a trading company or manufacture? A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory. 2. Q: What's your factory workshops ? A: My factoryproduce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc. Warmly welcome to visit & test my factory any time. 3. Q: How about your vertical slurry pump price? A: We are sure our price is factory price, and insist high quality for our long term cooperation.

FAQ 1. Q: Are you a trading company or manufacture? A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory. 2. Q: What's your factory workshops ? A: My factoryproduce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc. Warmly welcome to visit & test my factory any time. 3. Q: How about your vertical slurry pump price? A: We are sure our price is factory price, and insist high quality for our long term cooperation.

4. Q: What is your vertical slurry pump material ?

A: For BP series vertical slurry pump, we produce high Cr Mo Ni alloy, rubber liner, cast iron, stainless steel, etc. Produce as your requirements is ok.

5. Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~30 QC.

6. Q: Is it easy for customers to change the parts by myself ?

A: yes, the structure is simple,customers can change it very easily. We will also supply you maintenance tools for free.

7. Q: How to do if the pump or parts have operation problem within your warranty?

A: Tell me details timely, and show me pictures, we will send you solution at once without any hesistation.

8. Q: Can you install the motor or diesel engine with the pump for us ?

A: yes, we can, it's no problem, we are experienced in this . 9: Q: .We don't know which pump model we need ,can you help us ?

A: yes, please tell me your detail requirements, include liquid, flow rate, head etc, my engineers team wiil calculate & select most suitable pump model for you, offer pump solution for you.

10. Q:How long can you reply us if we send an inquiry ?

A: Generall with in 2 hours, we will send you official quotation sheet, with price, technology data, performance curve, dimension etc. Our Services An Pump Machinery Company to Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock. Packaging & Shipping Submersible sump pump packing and shipping

Packaging & Shipping Submersible sump pump packing and shipping  Company Information Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.

Company Information Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.

![]() An pump machinery’s main products includes: slurry pump, desulfurization pump, gravel pump, mud pump, sewage pump, submersible pump, submersible sewage pump, impurity pump, large capacity split casing pump, high head multistage water pump,end suction pump, self priming pump, pump parts and ancillary equipment. which can satisfy different kinds of demands. Contact An Pump 24x7 service for your electric motor large capacity submersible sand pump:

An pump machinery’s main products includes: slurry pump, desulfurization pump, gravel pump, mud pump, sewage pump, submersible pump, submersible sewage pump, impurity pump, large capacity split casing pump, high head multistage water pump,end suction pump, self priming pump, pump parts and ancillary equipment. which can satisfy different kinds of demands. Contact An Pump 24x7 service for your electric motor large capacity submersible sand pump:  Roger Chen P: +86 311 899 40549 F: +86 311 862 71170 Office C: +86 150 3285 7866 Personal C: +86 137 805 12387 Wechat /whatsapp: +86 137 805 12387 Skype: chenroger1215 Web: www.angroupcn.com Email: roger at angroupcn.com Email: pump at angroupcn.com (Please put "@" to "at" when you send the email)

Roger Chen P: +86 311 899 40549 F: +86 311 862 71170 Office C: +86 150 3285 7866 Personal C: +86 137 805 12387 Wechat /whatsapp: +86 137 805 12387 Skype: chenroger1215 Web: www.angroupcn.com Email: roger at angroupcn.com Email: pump at angroupcn.com (Please put "@" to "at" when you send the email)

Applications of large capacity submersible pump The rugged BP,BPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

Applications of large capacity submersible pump The rugged BP,BPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in: • Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel and almost every other tank, pit or hole-in-the-ground slurry handling situation.

The BP/BPR design with either hard metal (BP) or elastomer covered (BPR) components makes it ideal for:

• Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Continuous or “snore” operation

• Heavy duties demanding cantilever shafts Pump Description Feature of large capacity submersible pump Wetted components are available in a wide range of alloys and elastomers, from which An Pump Machinery selects the optimum combination of materials for maximum resistance to wear in virtually any industrial application, including those demanding both abrasion and corrosion resistance and where larger particles or high density slurries are encountered. • Abrasion resistant high Cr alloy.

• Abrasion/corrosion-resistant alloy.

• Corrosion-resistant stainless steels. • Natural and synthetic elastomers.

No submerged bearing failures The robust cantilever shaft avoids the need for lower submerged bearings - which are often the source of premature bearing failure. • Heavy duty roller bearings, above mountingplate. • No submerged bearings.

No submerged bearing failures The robust cantilever shaft avoids the need for lower submerged bearings - which are often the source of premature bearing failure. • Heavy duty roller bearings, above mountingplate. • No submerged bearings.• Labyrinth/flinger bearing protection.

• Rigid, large diameter shaft. No shaft sealing problems The vertical cantilever design requires no shaft seal. No priming required The top and bottom inlet design is ideally suited for “snore” conditions. Less risk of blocking The screened inlets and large impeller passages reduce the risk of blockages. Zero ancillary water costs The vertical cantilever design with no gland or submerged bearings avoids the need for expensive gland or bearing flushing water.

Pump Performance Specifications of large capacity submersible pump

Pump Performance Specifications of large capacity submersible pump Type | Material | Flow | Head (m) | Max Power (kw) | Speed (rpm) |

40C-BP/R | Metal/Rubber | 7.2-39.6 | 3.9-27.4 | 15 | 1000-2200 |

65D-BP/R | Metal/Rubber | 19.08-102.6 | 5-31.1 | 30 | 700-1500 |

100E-BP/R | Metal/Rubber | 41.5-259.2 | 5.1-37.2 | 70 | 500-1200 |

150F-BP/R | Metal/Rubber | 115.2-576 | 6.7-35.7 | 110 | 500-1000 |

200F-BP/R | Metal/Rubber | 180-734.4 | 7.1-28.2 | 110 | 400-850 |

250S-BP/R | Metal/Rubber | 363-1188 | 7-36 | 200 | 400-750 |

300S-BP/R | Metal/Rubber | 385-1492 | 7.8-55 | 250 | 400-700 |

FAQ 1. Q: Are you a trading company or manufacture? A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory. 2. Q: What's your factory workshops ? A: My factoryproduce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc. Warmly welcome to visit & test my factory any time. 3. Q: How about your vertical slurry pump price? A: We are sure our price is factory price, and insist high quality for our long term cooperation.

FAQ 1. Q: Are you a trading company or manufacture? A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory. 2. Q: What's your factory workshops ? A: My factoryproduce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc. Warmly welcome to visit & test my factory any time. 3. Q: How about your vertical slurry pump price? A: We are sure our price is factory price, and insist high quality for our long term cooperation. 4. Q: What is your vertical slurry pump material ?

A: For BP series vertical slurry pump, we produce high Cr Mo Ni alloy, rubber liner, cast iron, stainless steel, etc. Produce as your requirements is ok.

5. Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~30 QC.

6. Q: Is it easy for customers to change the parts by myself ?

A: yes, the structure is simple,customers can change it very easily. We will also supply you maintenance tools for free.

7. Q: How to do if the pump or parts have operation problem within your warranty?

A: Tell me details timely, and show me pictures, we will send you solution at once without any hesistation.

8. Q: Can you install the motor or diesel engine with the pump for us ?

A: yes, we can, it's no problem, we are experienced in this . 9: Q: .We don't know which pump model we need ,can you help us ?

A: yes, please tell me your detail requirements, include liquid, flow rate, head etc, my engineers team wiil calculate & select most suitable pump model for you, offer pump solution for you.

10. Q:How long can you reply us if we send an inquiry ?

A: Generall with in 2 hours, we will send you official quotation sheet, with price, technology data, performance curve, dimension etc. Our Services An Pump Machinery Company to Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock.

Packaging & Shipping Submersible sump pump packing and shipping

Packaging & Shipping Submersible sump pump packing and shipping  Company Information Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.

Company Information Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.

Roger Chen P: +86 311 899 40549 F: +86 311 862 71170 Office C: +86 150 3285 7866 Personal C: +86 137 805 12387 Wechat /whatsapp: +86 137 805 12387 Skype: chenroger1215 Web: www.angroupcn.com Email: roger at angroupcn.com Email: pump at angroupcn.com (Please put "@" to "at" when you send the email)

Roger Chen P: +86 311 899 40549 F: +86 311 862 71170 Office C: +86 150 3285 7866 Personal C: +86 137 805 12387 Wechat /whatsapp: +86 137 805 12387 Skype: chenroger1215 Web: www.angroupcn.com Email: roger at angroupcn.com Email: pump at angroupcn.com (Please put "@" to "at" when you send the email) Related Keywords

Related Keywords