Hebei Best Stainless Steel Welding Electrodes E308L-16

- Min. Order:

- 1 kilogram

- Min. Order:

- 1 kilogram

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 6000 Ton/Tons per Year |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

We are factory!

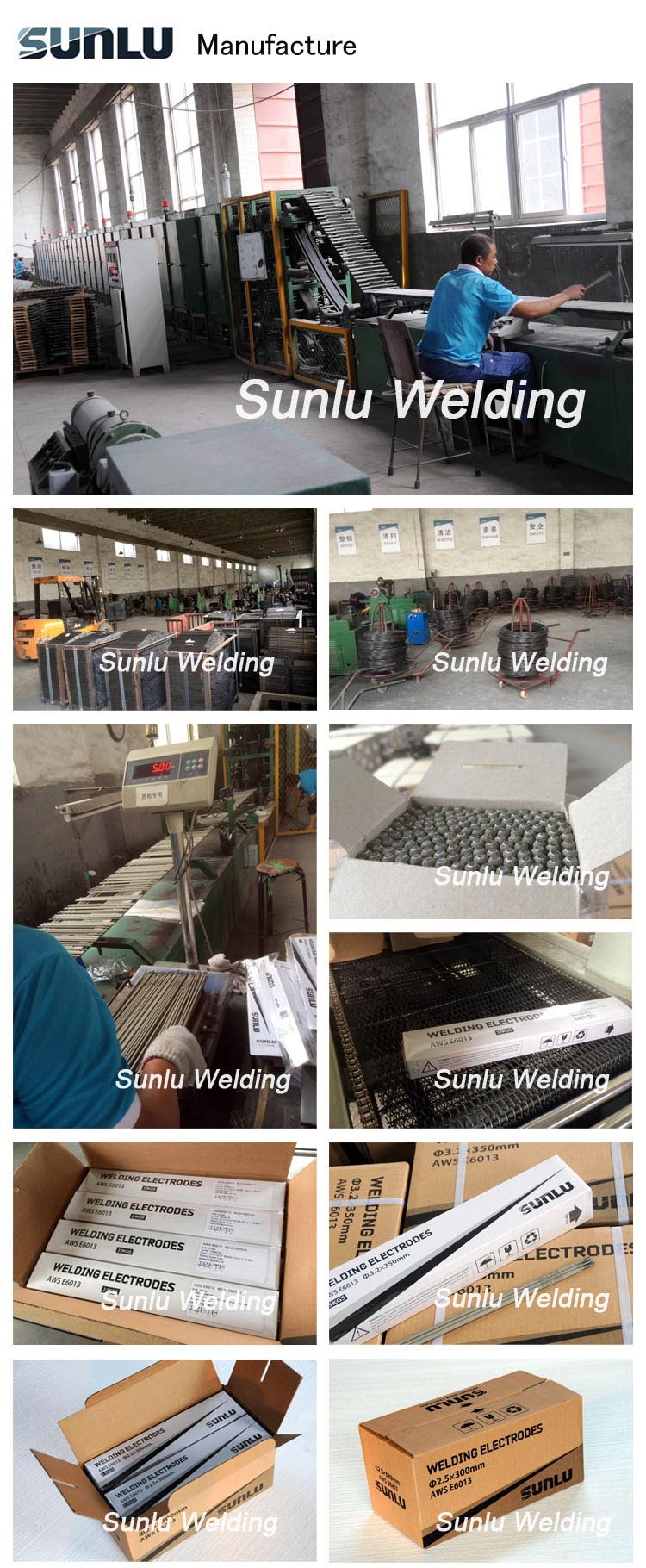

Shijiazhuang Shuanglu Machinery Co., Ltd.("Shuanglu" and "SUNLU" for short), as a member of China Welding Association (CWA) and one of the appointed manufacturers of China National Electric Equipment Corporation (CNEEC), manufactures complete welding electrode product.

Introduction:

E308L-16 is a kind of ultra-low-carbon Cr18Ni12Mo2 stainless steel electrode with lime-titania type coating. The carbon content of the deposited metal is lower than or equal to 0.04%. It has excellent heat-resistance, corrosion-resistance, crack-resistance, blowhole-resistance and welding performance. The coating has red-resistance and high strength. AC/DC.

Uses:

Used for welding equipment of urea, synthetic fiber, etc. and stainless steel structures of the same types, and also used for Cr stainless steel which does not need heat treatment after welding, composite steel, dissimilar steel, etc.

Chemical Composition of Deposited Metal (%)

| |||||||||||||||||||

| |||||||||||||||||||

| |||||||||||||||||||

| |||||||||||||||||||

More detailed and photos, please check our website:

WWW.SUNLUWELDING.COM

Related Keywords