Welding Rod Raw Material e7018 And Welding Electrode Supplier

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

SHIJIAZHUANG SHUANGLU MACHINERYCO.,LTD. Welding Rod Raw Material e7018 And Welding Electrode Supplier Description 1. We are professional and qualified manufacture for carbon steel welding electrodes: E7018. 2. Size: 2.0mm, 2.5mm, 3.2mm, 4.0mm, 5.0mm. 3. Packing: 2.5kg/box, 5kg/box, 20kg/carton. 4. High titanium type welding electrodes used for welding in all positions. 5. Factory supply directly. Our own brand for welding electrodes is SUNLU BRAND, we can do OEM package as clients required if you need. 6. Stable quality and sweet after sale service guarantee. Product Description Welding Electrodes E7018 AWS E7018 is a kind of carbon steel electrode with iron powder low-hydrogen potassium type coating. AC/DC. The deposition efficiency can be improved due to the iron powder in the coating. It has stable arc, fewer spatters, good slag detachability and excellent welding performance. The deposited metal has excellent mechanical properties. All-position welding. Uses Used for welding carbon steel and low-alloy steel structures, such as 16Mn, etc. Notes on Usage

SHIJIAZHUANG SHUANGLU MACHINERYCO.,LTD. Welding Rod Raw Material e7018 And Welding Electrode Supplier Description 1. We are professional and qualified manufacture for carbon steel welding electrodes: E7018. 2. Size: 2.0mm, 2.5mm, 3.2mm, 4.0mm, 5.0mm. 3. Packing: 2.5kg/box, 5kg/box, 20kg/carton. 4. High titanium type welding electrodes used for welding in all positions. 5. Factory supply directly. Our own brand for welding electrodes is SUNLU BRAND, we can do OEM package as clients required if you need. 6. Stable quality and sweet after sale service guarantee. Product Description Welding Electrodes E7018 AWS E7018 is a kind of carbon steel electrode with iron powder low-hydrogen potassium type coating. AC/DC. The deposition efficiency can be improved due to the iron powder in the coating. It has stable arc, fewer spatters, good slag detachability and excellent welding performance. The deposited metal has excellent mechanical properties. All-position welding. Uses Used for welding carbon steel and low-alloy steel structures, such as 16Mn, etc. Notes on Usage | 1. The electrodes must be baked under 300~350°C for an hour before welding and used as soon as baking is completed. 2. The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away before welding. 3. When welding, short arc must be used and stringer bead is suitable. |

Chemical Composition | C | Mn | Si | S | P | Ni | Mo | Cr | V |

Guarantee Value | ≤0.12 | ≤1.60 | ≤0.75 | ≤0.035 | ≤0.040 | ≤0.30 | ≤0.30 | ≤0.20 | ≤0.08 |

Test Item | Rm(MPa) | ReL(Mpa) | A(%) | KV2(J) |

Guarantee Value | ≥490 | ≥400 | ≥22 | ≥27(-30°C) |

Electrode Diameter(mm) | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

Length(mm) | 300 | 350 | 400 | 400 |

Welding Current (A) | 60~100 | 80~140 | 110~210 | 160~230 |

Packaging & Shipping Packaging:2.5mm: 2.5kg / box / shrink wrapped, 20kg (4boxes) / carton, 1,000kg (50cartons) / pallet . 3.2mm: 5kg / box / shrink wrapped, 20kg (4boxes) / carton, 1,000kg (50cartons) / pallet. our own packing is SUNLU brand,we also can do OEM packing for you.

Packaging & Shipping Packaging:2.5mm: 2.5kg / box / shrink wrapped, 20kg (4boxes) / carton, 1,000kg (50cartons) / pallet . 3.2mm: 5kg / box / shrink wrapped, 20kg (4boxes) / carton, 1,000kg (50cartons) / pallet. our own packing is SUNLU brand,we also can do OEM packing for you.

Shipping:15 days after we receiving the advance payment.

Shipping:15 days after we receiving the advance payment.

Our Services We will give our customers best services for welding electrodes ,raw materials and welding electrodes production line. Quality control All the raw materials will be do strict inspection before use. Our products meet international standards, and have strict internal control standards. Good operating performance ---- small splash ,no smoking,,forming good. Certificates and honors We has passed the certification of ISO9001:2008 Quality Management System in 2005 we get a lot of honor and the quality of the welding electrodes also won customers' affirmation .

Our Services We will give our customers best services for welding electrodes ,raw materials and welding electrodes production line. Quality control All the raw materials will be do strict inspection before use. Our products meet international standards, and have strict internal control standards. Good operating performance ---- small splash ,no smoking,,forming good. Certificates and honors We has passed the certification of ISO9001:2008 Quality Management System in 2005 we get a lot of honor and the quality of the welding electrodes also won customers' affirmation .

Company Information Shijiazhuang Shuanglu Machinery Co., Ltd.(“Shuanglu” for short), as a member of China Welding Association (CWA) and one of the appointed manufacturers of China National Electric Equipment Corporation (CNEEC), produces complete welding electrode production line. With rich experience, delicate equipment, advancing process, stable quality and strong technical force, Shuanglu has grown into a comprehensive mechanical Industry company integrating R&D, design, manufacture, sales and service.

Company Information Shijiazhuang Shuanglu Machinery Co., Ltd.(“Shuanglu” for short), as a member of China Welding Association (CWA) and one of the appointed manufacturers of China National Electric Equipment Corporation (CNEEC), produces complete welding electrode production line. With rich experience, delicate equipment, advancing process, stable quality and strong technical force, Shuanglu has grown into a comprehensive mechanical Industry company integrating R&D, design, manufacture, sales and service.  Our Company Exhibition SUNLU had been attended exhibition in Dubai.

Our Company Exhibition SUNLU had been attended exhibition in Dubai.

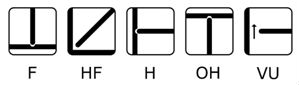

FAQ ELECTRIC SHOCK can kill. Do not permit electrically live parts or electrodes to contact skin, clothing or gloves if they are wet. Insulate yourself from work and ground. FUMES AND GASES can be dangerous to your health. Keep fumes and gases away from your breathing zone and general area. Keep your head out of fumes... Use enough ventilation or exhaust at the arc or both ARC RAYS can injure eyes and barn skin. Wear correct eye, ear.And body protection. Welding position

FAQ ELECTRIC SHOCK can kill. Do not permit electrically live parts or electrodes to contact skin, clothing or gloves if they are wet. Insulate yourself from work and ground. FUMES AND GASES can be dangerous to your health. Keep fumes and gases away from your breathing zone and general area. Keep your head out of fumes... Use enough ventilation or exhaust at the arc or both ARC RAYS can injure eyes and barn skin. Wear correct eye, ear.And body protection. Welding position

Related Keywords

Related Keywords

You May Also Like

You May Also Like