Cryogel Z Aerogels used for refineries

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT

- Min. Order:

- 50 Square Meter

- Min. Order:

- 50 Square Meter

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Huangpu, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500000 m3 per month |

| Supply Ability: | 500000 m3 per month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT |

| Certificate: | ASTM 1728 |

| HS Code: | 7019909000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Huangpu,Shenzhen |

Cryogel Z Aerogels used for refineries

For gas processing plants to choose the Cryogel Z Aerogels used for refineries

After 2 years of use, the Thermal Insulation Material effect of traditional insulation materials will begin to decline year by year. The local temperature of the main combustion zone in the furnace will reach 80-120°C. The surface temperature of the convection heat exchanger will reach 40°C or more, and the energy loss will be exceeded. Increase and cause security risks.

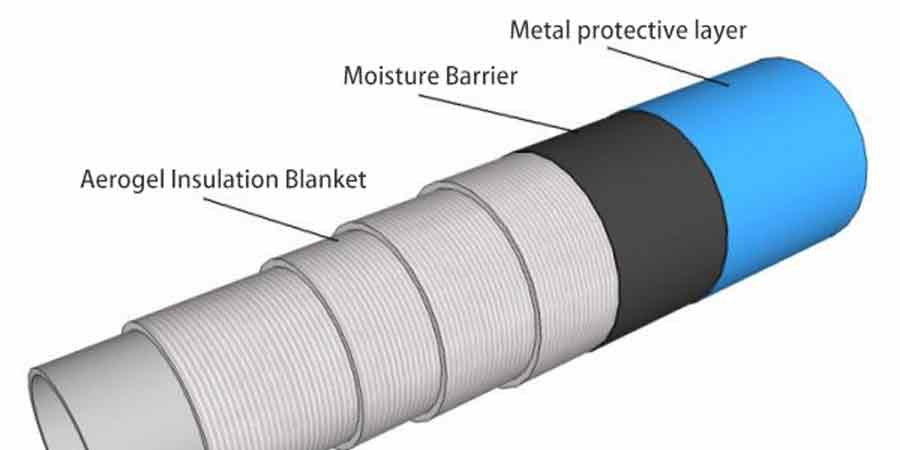

Cryogel Aerogel Blankets Description

Superior Thermal Performance

Up to five times better high-thermal performance than competing insulation products"

Reduced Thickness and Profile of Silica Aerogel

Equal thermal resistance at a fraction of the thickness. Maximize process infrastructure and resolve mechanical clashes

Less Time and Labor to Install, Aerogel Insulation Blanket is easily cut and conformed to complex shapes, tight curvatures, and spaces with restricted access. Silica Aerogel Insulation Blanket supports more insulation coverage per man hour than traditional forms of insulation.

Pyrogel Thermal Insulation Material Specification

|

Specification |

|

HT650-3 |

HT650-5 |

HT650-6 |

HT650-10 |

||

|

Thickness |

3mm |

5mm |

6mm |

10mm |

|||

|

Length |

57m |

42m |

38m |

25m |

|||

|

Width |

1.5m |

||||||

|

Color |

White |

||||||

|

Suggested Working Temperature : |

-50 ~650℃ |

||||||

|

Notes: Sizes could be on customers` request |

|||||||

|

Technical Data |

|

Vaule |

Test Method |

||||

|

Size Stability |

1% |

GB/T 8811 |

|||||

|

Shrinkage Temperature under pressure |

800℃ |

GB/T 11835 |

|||||

|

Compressive Property |

@10% 60Kpa @20% 120Kpa |

GB/T 13480 |

|||||

|

Fire Rating |

A1 |

GB/T 8624 |

|||||

|

Tensile Strength |

1400 KPa |

GB/T 17911 |

|||||

|

Thermal Conductivity Average Temp |

25℃ |

0.018 |

GB/T 10295 |

||||

|

200℃ |

0.024 |

||||||

|

300℃ |

0.032 |

||||||

|

400℃ |

0.042 |

||||||

|

500℃ |

0.051 |

||||||

|

650℃ |

0.062 |

||||||

|

Function |

For 300℃~650℃ pipes and equipment insulation |

||||||

|

Application |

Super pressure vapor pipes and equipment insulation, industrial furnace insulation |

||||||

Pyrogel HPSAerogels used for gas processing plants Advantages

Reusable - Lower Lifetime Costs,Pyrogel Aerogels is easily removed for inspection and maintenance and can be reused in original service, reducing downtime and eliminating the need to purchase replacement insulation at regular maintenance cycles

Physically Robust and Impact Resistant

Soft and flexible but with excellent spring back,Pyrogel recovers its thermal performance even after compression events as high as 100 psi, protecting critical assets from compromise due to tool strikes, footfalls, lifting, and transportation

Logistics Savings - Time and Money

Reduced material volume, high packing density, and low scrap rates can reduce shipping volumes by a factor of five or more compared to rigid, pre-formed high-temperature insulation

Pyrogel HPSAerogels used for gas processing plants Application

(1)Pipe insulation

(2) Equipment insulation

(3) Tank thermal insulation

(4) Vehicle insulation

(5) High-end building, roof and floor heating insulation

(6) Chemical, biological pharmaceuticals pipeline insulation

Pyrogel HPSAerogels used for gas processing plants

It has the thermal insulation performance and surface hydrophobicity and excellent flame retardant properties.

Our service:

Your inquiry regard to our product will be replied within 24hours

Well-trained & experienced staff are to answer all your inquiries in English of course

Working time:8:30am-6:00pm, Monday to Friday

OEM&ODM projects are highly welcomed. We have strong R&D team here to help

Your business relationship with us will be confidential to any third party

Good after-sales service offered, please get back if you got any questions

Related Keywords