30 years boiler manufacturer professional boiler manufacturer national patent boiler manufacturer

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

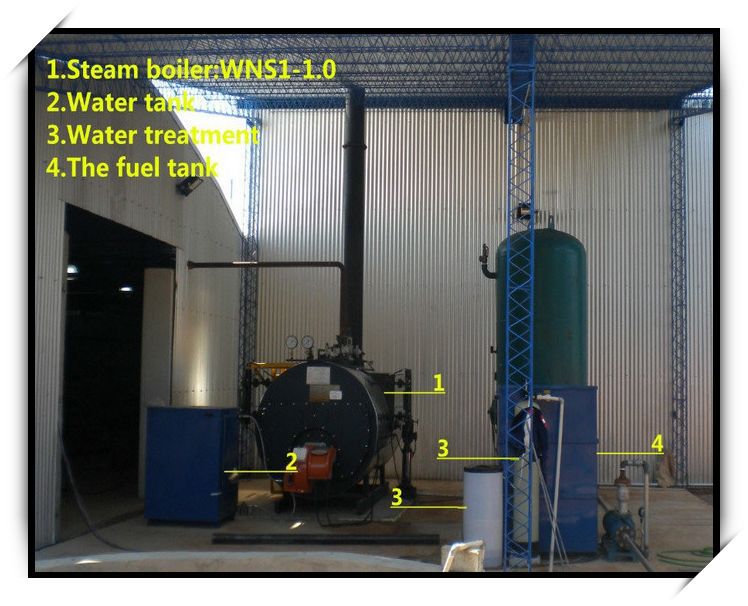

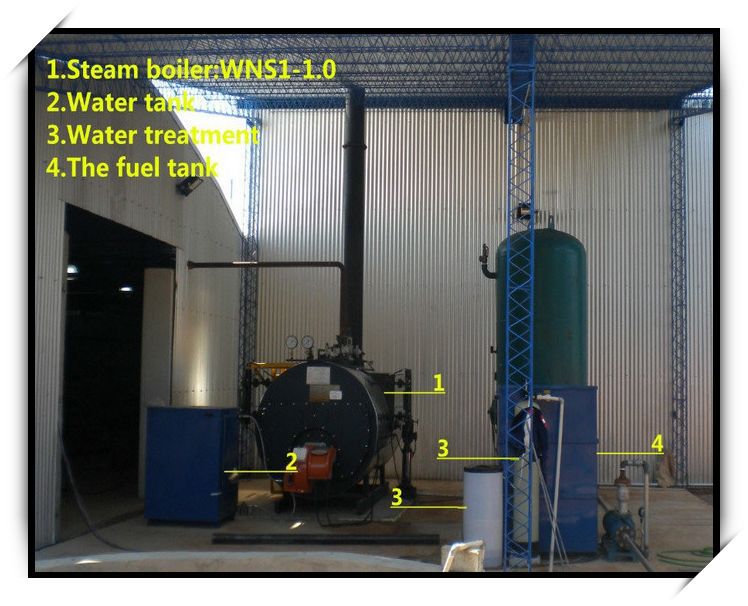

30 years boiler manufacturer professional boiler manufacturer national patent boiler manufacturer WNS steam boiler  General features of WNS series steam boiler: 1. horizontal , gas & oil fired , water tube, industrial and low pressure; 2. wetback and three-backhaulstructure design; 3. With high efficiency economizer, the thermal efficiency can reach more than 90%. 4. The spring-loaded type explosion door ensures the boiler safety 5. The removable smoke boxfacilitates the maintenance 6. Internal micro positive pressure combustionreduces the low temperature corrosion. 7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.

General features of WNS series steam boiler: 1. horizontal , gas & oil fired , water tube, industrial and low pressure; 2. wetback and three-backhaulstructure design; 3. With high efficiency economizer, the thermal efficiency can reach more than 90%. 4. The spring-loaded type explosion door ensures the boiler safety 5. The removable smoke boxfacilitates the maintenance 6. Internal micro positive pressure combustionreduces the low temperature corrosion. 7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.  The product advantage: 1. Subulate furnace and corrugated furnace combination Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction 2. Smooth tube and spirally corrugated tube combination The smooth tube Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ; The spirally corrugated tube Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself. 3. The furnace sits in line with the combustion Function: (1) Make the structure more compact; (2) prolong its service life; Mark: The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

The product advantage: 1. Subulate furnace and corrugated furnace combination Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction 2. Smooth tube and spirally corrugated tube combination The smooth tube Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ; The spirally corrugated tube Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself. 3. The furnace sits in line with the combustion Function: (1) Make the structure more compact; (2) prolong its service life; Mark: The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

The measures of quality assurance as follow: 1. Strength calculation report with applied materials information; 2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; 3. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler; 4. Hydraulic test report: ensure the standard working pressure and safety;

The measures of quality assurance as follow: 1. Strength calculation report with applied materials information; 2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; 3. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler; 4. Hydraulic test report: ensure the standard working pressure and safety;

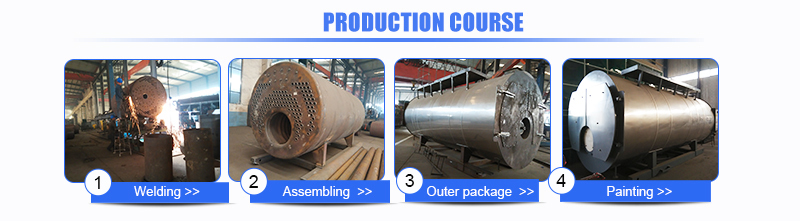

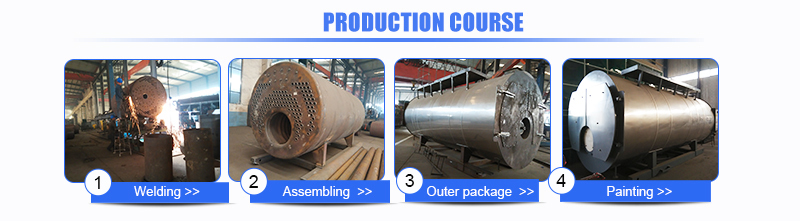

production courses 1 YLW

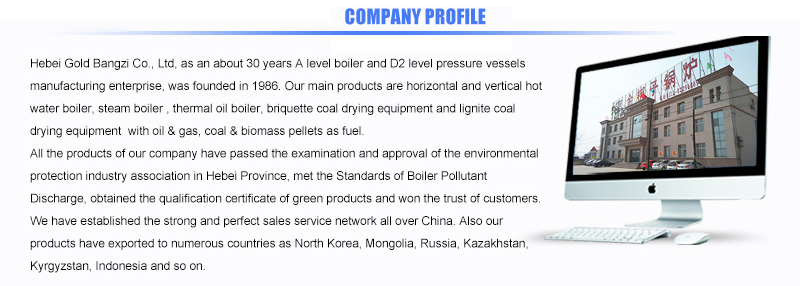

Company Information

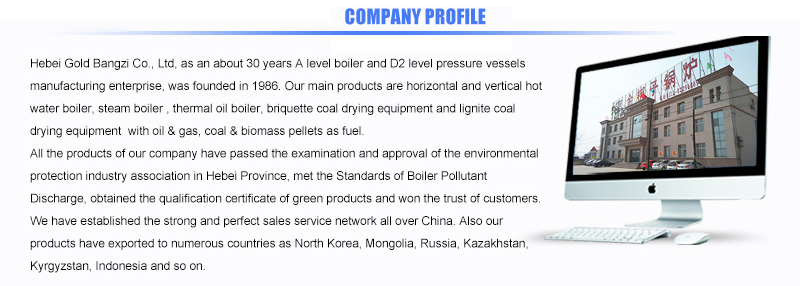

Company Information  Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.  Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.

Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.  Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.  Contact Leeson Zhou Tel/Fax: +86 311 83893700 Cell/Whatsapp/Wechat: +86 13833185003 Website: www.bzboilers.com

Contact Leeson Zhou Tel/Fax: +86 311 83893700 Cell/Whatsapp/Wechat: +86 13833185003 Website: www.bzboilers.com

General features of WNS series steam boiler: 1. horizontal , gas & oil fired , water tube, industrial and low pressure; 2. wetback and three-backhaulstructure design; 3. With high efficiency economizer, the thermal efficiency can reach more than 90%. 4. The spring-loaded type explosion door ensures the boiler safety 5. The removable smoke boxfacilitates the maintenance 6. Internal micro positive pressure combustionreduces the low temperature corrosion. 7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.

General features of WNS series steam boiler: 1. horizontal , gas & oil fired , water tube, industrial and low pressure; 2. wetback and three-backhaulstructure design; 3. With high efficiency economizer, the thermal efficiency can reach more than 90%. 4. The spring-loaded type explosion door ensures the boiler safety 5. The removable smoke boxfacilitates the maintenance 6. Internal micro positive pressure combustionreduces the low temperature corrosion. 7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.  The product advantage: 1. Subulate furnace and corrugated furnace combination Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction 2. Smooth tube and spirally corrugated tube combination The smooth tube Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ; The spirally corrugated tube Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself. 3. The furnace sits in line with the combustion Function: (1) Make the structure more compact; (2) prolong its service life; Mark: The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

The product advantage: 1. Subulate furnace and corrugated furnace combination Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction 2. Smooth tube and spirally corrugated tube combination The smooth tube Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ; The spirally corrugated tube Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself. 3. The furnace sits in line with the combustion Function: (1) Make the structure more compact; (2) prolong its service life; Mark: The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

The measures of quality assurance as follow: 1. Strength calculation report with applied materials information; 2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; 3. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler; 4. Hydraulic test report: ensure the standard working pressure and safety;

The measures of quality assurance as follow: 1. Strength calculation report with applied materials information; 2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; 3. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler; 4. Hydraulic test report: ensure the standard working pressure and safety; | Projects | unit | WNS1 | WNS2 | WNS4 | WNS6 | WNS10 | WNS15 | WNS20 | |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 | 20 | |

| Nominal steam pressure | Mpa | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Nominal steam temperature | °c | 194 | |||||||

| Rated inlet water temperature | °c | 20 | |||||||

| body heating surface | m² | 25.5 | 60 | 111 | 160 | 260 | 380 | 482 | |

| Economizer heating surface | m² | 5 | 10 | 16 | 25 | 30 | 46 | 62 | |

| Design thermal efficiency | % | 91.8 | |||||||

| Design environment temprature | °c | 20 | |||||||

| Design blowdown rate | % | 4 | |||||||

| Net weight of boiler | t | 6.5 | 9.8 | 14.8 | 20.7 | 30.4 | 43.3 | 50.4 | |

| operational water volume | t | 3 | 5 | 7.5 | 10.7 | 16.7 | 25 | 31.5 | |

| full water volume | t | 4 | 6.8 | 10 | 14.6 | 22.3 | 31.1 | 36.6 | |

| Fuel consumption | Natural gas | Nm3/h | 75.4 | 149 | 298 | 447 | 743.6 | 1084.4 | 1444.3 |

| Diesel | kg/h | 64 | 132 | 265 | 382 | 636 | 951 | 1267.6 | |

Company Information

Company Information  Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.  Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.

Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.  Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.  Contact Leeson Zhou Tel/Fax: +86 311 83893700 Cell/Whatsapp/Wechat: +86 13833185003 Website: www.bzboilers.com

Contact Leeson Zhou Tel/Fax: +86 311 83893700 Cell/Whatsapp/Wechat: +86 13833185003 Website: www.bzboilers.com You May Also Like

You May Also Like