Industrial steam boiler price

- Delivery Time:

- 35 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

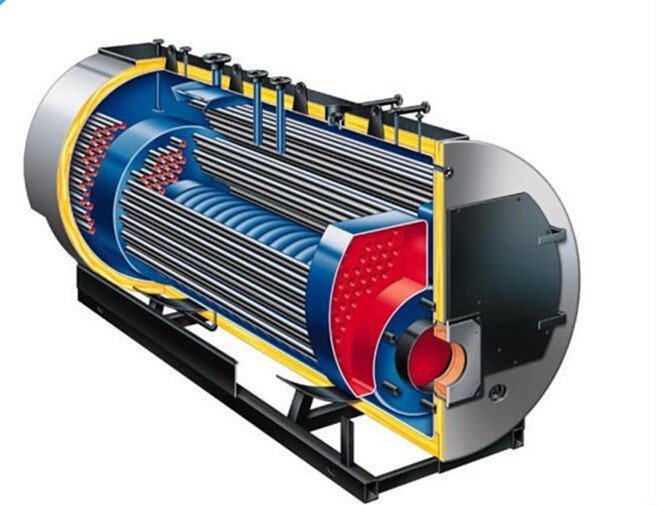

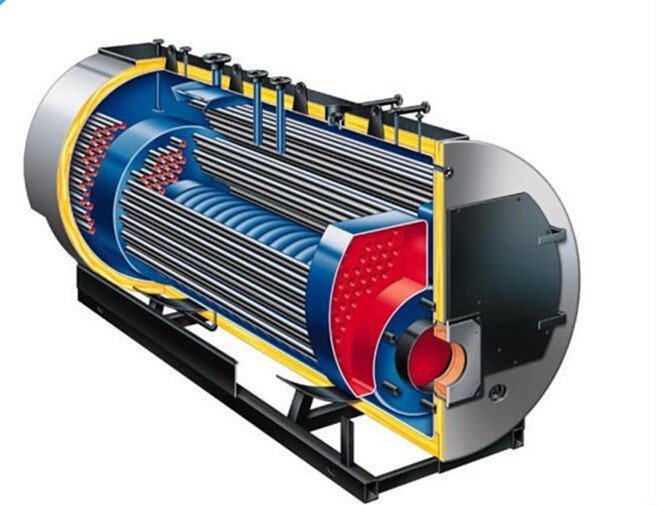

Industrial steam boiler price product description Product introduction of WNS Series gas oil boiler This series boiler is three-return fire tube steam boiler. It equipped with a bias furnace tube structure, and high temperature gas into the atmosphere through three-return smoke tube, smoke chamber. It equipped with good performance burner and advanced techniques. The burning control, water feed, programs run, etc, is full automatic. This fantasy boiler is safe and reliable, and also has the advantage of compact structure, simple operation, easy installation, high efficiency, less pollution and noise, etc.

Structure Features: 1. The design performance of boiler is advanced. The boiler body is the overall structure. The burner was assembled in the first smoke cover. The body arranges heating surface and combustion chamber with a reasonable, compact structure .so the structure has a low consumption in steel. Packaging shape is rectangular, and makes the boiler performance, weight, structure, size, appearance more advanced and beautiful than domestic products. The boiler feed water equipment is integrated with the body, so it do not need another foundation. 2. The water cycle is simple, and water quality can be guaranteed.

Structure Features: 1. The design performance of boiler is advanced. The boiler body is the overall structure. The burner was assembled in the first smoke cover. The body arranges heating surface and combustion chamber with a reasonable, compact structure .so the structure has a low consumption in steel. Packaging shape is rectangular, and makes the boiler performance, weight, structure, size, appearance more advanced and beautiful than domestic products. The boiler feed water equipment is integrated with the body, so it do not need another foundation. 2. The water cycle is simple, and water quality can be guaranteed.  Technical parameters of natural gas or diesel fired steam boilers

Technical parameters of natural gas or diesel fired steam boilers

Advantages 1. The use of waveform furnace can not only enhance the heat transfer effect, and also promote oil combustion in the furnace. 2. Sweeping function can improve working conditions and extend its service life. 3. The unique design of the large burning chamber can increase the radiation of hearth heating area and reduce the volume of the boiler and NOX emissions. 4. Smoke pipes box around boiler uses multi-level sealing approaches. 5. Horizontal structure has area ample heated and adequate heat transfer. 6. It is equipped with advanced touch screen controller. 7. A variety of alarm interlock devices to ensure efficient, safe, reliable operation of the boiler. Application field 1. Industrial user: pharmaceutical, paper, tobacco, printing and dyeing, garment and other industries; 2. Civil: catering , laundry, ( hospital ) disinfection, sauna , etc ; 3. By steam - water heat exchange for heating systems ( air conditioning , radiators , floor heating , etc. ) of hot water ; 4. Provide power for the lithium bromide absorption chiller. Installation notices 1. The boiler is provided with blast doors, the explosion door location should be conducive to venting. 2. Installation of boiler and auxiliary equipment, water treatment equipment, etc. shall comply with the technical requirements of equipment manufacturers. 3. Equipment installation, you should avoid equipment, installation materials focus stacking on the floor.  production courses

production courses  Company Showing

Company Showing  Company Introduction 1, Spirit: Supply Reliable & High Efficient Heating System. 2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer. 3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification. 4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China. 5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection. 6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,. We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide! Certifications

Company Introduction 1, Spirit: Supply Reliable & High Efficient Heating System. 2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer. 3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification. 4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China. 5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection. 6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,. We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide! Certifications  customers

customers  Our Services 1. The boiler body guarantee is 2 years, Auxiliary machine part guarantee is 3 years. 2.During the warranty period,if the main body defective as the bad quality without any workers wrong operation ,Henan Province Xinxiang Hebei gold bangzi Boiler Co.,ltd should replace the parts for free or prepare the goods for free. 3. Bangzi should provide boiler technical service and operation guidance life long . 4.Regarding to the installation and training,the buyer bear all the correlative charge(accommodation and food ,return air ticket.) If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel/whatsapp: +86-18630196461 Email: linda at bangziboiler.com

Our Services 1. The boiler body guarantee is 2 years, Auxiliary machine part guarantee is 3 years. 2.During the warranty period,if the main body defective as the bad quality without any workers wrong operation ,Henan Province Xinxiang Hebei gold bangzi Boiler Co.,ltd should replace the parts for free or prepare the goods for free. 3. Bangzi should provide boiler technical service and operation guidance life long . 4.Regarding to the installation and training,the buyer bear all the correlative charge(accommodation and food ,return air ticket.) If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel/whatsapp: +86-18630196461 Email: linda at bangziboiler.com

Structure Features: 1. The design performance of boiler is advanced. The boiler body is the overall structure. The burner was assembled in the first smoke cover. The body arranges heating surface and combustion chamber with a reasonable, compact structure .so the structure has a low consumption in steel. Packaging shape is rectangular, and makes the boiler performance, weight, structure, size, appearance more advanced and beautiful than domestic products. The boiler feed water equipment is integrated with the body, so it do not need another foundation. 2. The water cycle is simple, and water quality can be guaranteed.

Structure Features: 1. The design performance of boiler is advanced. The boiler body is the overall structure. The burner was assembled in the first smoke cover. The body arranges heating surface and combustion chamber with a reasonable, compact structure .so the structure has a low consumption in steel. Packaging shape is rectangular, and makes the boiler performance, weight, structure, size, appearance more advanced and beautiful than domestic products. The boiler feed water equipment is integrated with the body, so it do not need another foundation. 2. The water cycle is simple, and water quality can be guaranteed.  Technical parameters of natural gas or diesel fired steam boilers

Technical parameters of natural gas or diesel fired steam boilers | Projects | unit | WNS1 | WNS2 | WNS4 | WNS6 | WNS10 | WNS15 | WNS20 | |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 | 20 | |

| Nominal steam pressure | Mpa | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Nominal steam temperature | °c | 194 | |||||||

| Rated inlet water temperature | °c | 20 | |||||||

| body heating surface | m² | 25.5 | 60 | 111 | 160 | 260 | 380 | 482 | |

| Economizer heating surface | m² | 5 | 10 | 16 | 25 | 30 | 46 | 62 | |

| Design thermal efficiency | % | 91.8 | |||||||

| Design environment temprature | °c | 20 | |||||||

| Design blowdown rate | % | 4 | |||||||

| Net weight of boiler | t | 6.5 | 9.8 | 14.8 | 20.7 | 30.4 | 43.3 | 50.4 | |

| operational water volume | t | 3 | 5 | 7.5 | 10.7 | 16.7 | 25 | 31.5 | |

| full water volume | t | 4 | 6.8 | 10 | 14.6 | 22.3 | 31.1 | 36.6 | |

| Fuel consumption | Natural gas | Nm3/h | 75.4 | 149 | 298 | 447 | 743.6 | 1084.4 | 1444.3 |

| Diesel | kg/h | 64 | 132 | 265 | 382 | 636 | 951 | 1267.6 | |

production courses

production courses  Company Showing

Company Showing  Company Introduction 1, Spirit: Supply Reliable & High Efficient Heating System. 2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer. 3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification. 4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China. 5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection. 6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,. We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide! Certifications

Company Introduction 1, Spirit: Supply Reliable & High Efficient Heating System. 2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer. 3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification. 4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China. 5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection. 6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,. We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide! Certifications  customers

customers  Our Services 1. The boiler body guarantee is 2 years, Auxiliary machine part guarantee is 3 years. 2.During the warranty period,if the main body defective as the bad quality without any workers wrong operation ,Henan Province Xinxiang Hebei gold bangzi Boiler Co.,ltd should replace the parts for free or prepare the goods for free. 3. Bangzi should provide boiler technical service and operation guidance life long . 4.Regarding to the installation and training,the buyer bear all the correlative charge(accommodation and food ,return air ticket.) If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel/whatsapp: +86-18630196461 Email: linda at bangziboiler.com

Our Services 1. The boiler body guarantee is 2 years, Auxiliary machine part guarantee is 3 years. 2.During the warranty period,if the main body defective as the bad quality without any workers wrong operation ,Henan Province Xinxiang Hebei gold bangzi Boiler Co.,ltd should replace the parts for free or prepare the goods for free. 3. Bangzi should provide boiler technical service and operation guidance life long . 4.Regarding to the installation and training,the buyer bear all the correlative charge(accommodation and food ,return air ticket.) If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel/whatsapp: +86-18630196461 Email: linda at bangziboiler.com You May Also Like

You May Also Like