China coal boiler manufacturers thermal fluid boiler

- Delivery Time:

- 35 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

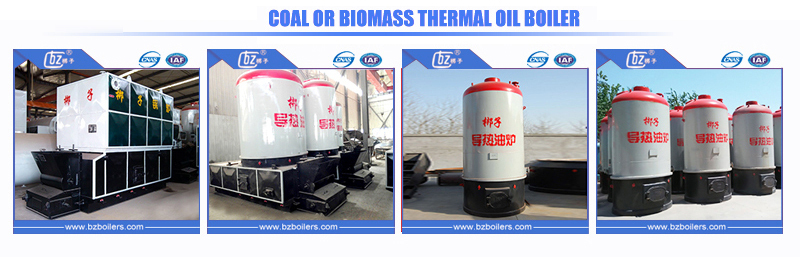

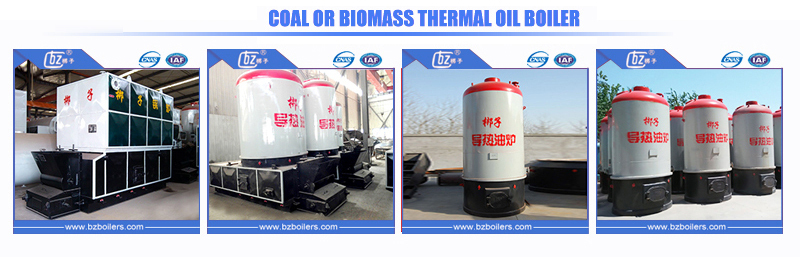

China coal boiler manufacturers thermal fluid boiler Product Description China coal boiler manufacturers supply coal thermal oil boiler well. The coal therml oil boiler is horizontal, industrial use, automatic chain grate ( travelling grate ) stoker,water tube compositional and forced circulation boiler. It takes coal, biomass pellet, wood pellet, sawdust, wood chips as fuel. The front radiant heating area consists of monolayer closely-arranged round coil. And the back convection heating area consists of snakelike coils.The boiler comprises the upper body and the below combustor. The fuel burns in the below combustor and the coils in the upper body absorb the energy and then transfer the heat to the medium.  The features: 1 Take monolayer (double-layer) closely aligned round coils as radiant heating area The sufficient heating area reduces not only the medium resistance inside the furnace, but also the thermal load on the coil surface so as to ensure the safer usage of the thermal oil. 2 The ceiling coil The ceiling coil on the top of the radiant heating surface can protect the furnace top from being burned out. 3 Waste heat boiler or air preheater The waste heat boiler (air preheater) is mounted to recover the energy in the exhaust gas so as to improve the efficiency. 4 Rational medium procedure The medium enters from the low position and flows out from the high position. In this way, the exhaust gas can be discharged out of the boiler smoothly. 5 Special furnace arch and fire grate design With the special design, the boiler can achieve the independent regulation on air volume, which makes the sufficient and full combustion. 6 Convenient installation The installation is very convenient and flexible, just need to place the boiler on the foundation. Technical parameters from coal boiler manufacturer

The features: 1 Take monolayer (double-layer) closely aligned round coils as radiant heating area The sufficient heating area reduces not only the medium resistance inside the furnace, but also the thermal load on the coil surface so as to ensure the safer usage of the thermal oil. 2 The ceiling coil The ceiling coil on the top of the radiant heating surface can protect the furnace top from being burned out. 3 Waste heat boiler or air preheater The waste heat boiler (air preheater) is mounted to recover the energy in the exhaust gas so as to improve the efficiency. 4 Rational medium procedure The medium enters from the low position and flows out from the high position. In this way, the exhaust gas can be discharged out of the boiler smoothly. 5 Special furnace arch and fire grate design With the special design, the boiler can achieve the independent regulation on air volume, which makes the sufficient and full combustion. 6 Convenient installation The installation is very convenient and flexible, just need to place the boiler on the foundation. Technical parameters from coal boiler manufacturer

production courses Company Information

Company Information  Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.  Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.

Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.  Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.  Contact

Contact

The features: 1 Take monolayer (double-layer) closely aligned round coils as radiant heating area The sufficient heating area reduces not only the medium resistance inside the furnace, but also the thermal load on the coil surface so as to ensure the safer usage of the thermal oil. 2 The ceiling coil The ceiling coil on the top of the radiant heating surface can protect the furnace top from being burned out. 3 Waste heat boiler or air preheater The waste heat boiler (air preheater) is mounted to recover the energy in the exhaust gas so as to improve the efficiency. 4 Rational medium procedure The medium enters from the low position and flows out from the high position. In this way, the exhaust gas can be discharged out of the boiler smoothly. 5 Special furnace arch and fire grate design With the special design, the boiler can achieve the independent regulation on air volume, which makes the sufficient and full combustion. 6 Convenient installation The installation is very convenient and flexible, just need to place the boiler on the foundation. Technical parameters from coal boiler manufacturer

The features: 1 Take monolayer (double-layer) closely aligned round coils as radiant heating area The sufficient heating area reduces not only the medium resistance inside the furnace, but also the thermal load on the coil surface so as to ensure the safer usage of the thermal oil. 2 The ceiling coil The ceiling coil on the top of the radiant heating surface can protect the furnace top from being burned out. 3 Waste heat boiler or air preheater The waste heat boiler (air preheater) is mounted to recover the energy in the exhaust gas so as to improve the efficiency. 4 Rational medium procedure The medium enters from the low position and flows out from the high position. In this way, the exhaust gas can be discharged out of the boiler smoothly. 5 Special furnace arch and fire grate design With the special design, the boiler can achieve the independent regulation on air volume, which makes the sufficient and full combustion. 6 Convenient installation The installation is very convenient and flexible, just need to place the boiler on the foundation. Technical parameters from coal boiler manufacturer | projects | units | YLW-700 | YLW-1000 | YLW-1200 | YLW-1400 | YLW-2000 | YLW-2400 | YLW-2900 | YLW-3500 | YLW-4700 | YLW-6000 | YLW-7000 | YLW-10000 | YLW-18000 |

| rated thermal power | kw | 700 | 1000 | 1200 | 1400 | 2000 | 2400 | 2900 | 3500 | 4700 | 6000 | 7000 | 10000 | 18000 |

| rated working pressure | MPa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| highest working temperature | ℃ | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| oil volumn in the boiler | cube meters | 0.52 | 0.66 | 0.85 | 1.09 | 1.33 | 1.6 | 2.2 | 2.6 | 3.8 | 4.7 | 5.24 | 6.3 | 12.3 |

| cycle oil volumn | cube meters/h | 60 | 60 | 80 | 100 | 160 | 160 | 180 | 200 | 300 | 360 | 400 | 400 | 1000 |

| pipe diameter | DN | 100 | 125 | 125 | 125 | 150 | 150 | 150 | 200 | 200 | 250 | 250 | 300 | 350 |

| applicable fuel | Coal, biomass, biomass pellets, pellets, wood chips, wood pellets, wood, sawdust, solid fuel... | |||||||||||||

| thermal efficiency | % | more than 76% | more than 78% | more than 79% | more than 80% | |||||||||

| coal consumption | kg/h | 145 | 180 | 220 | 265 | 390 | 465 | 560 | 650 | 890 | 1120 | 1380 | 2200 | 3320 |

production courses

Company Information

Company Information  Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.  Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.

Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.  Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.  Contact

Contact

You May Also Like

You May Also Like