ISO standard Coal fired oil heat boiler for coal chemical industry

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

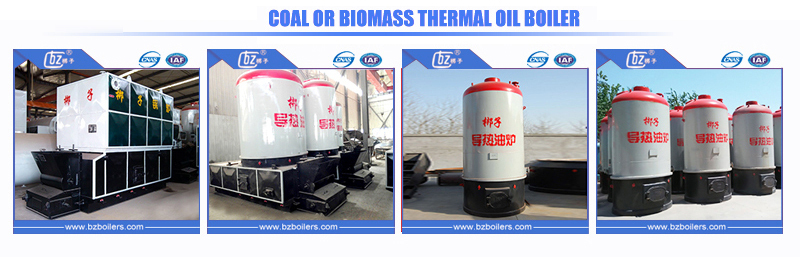

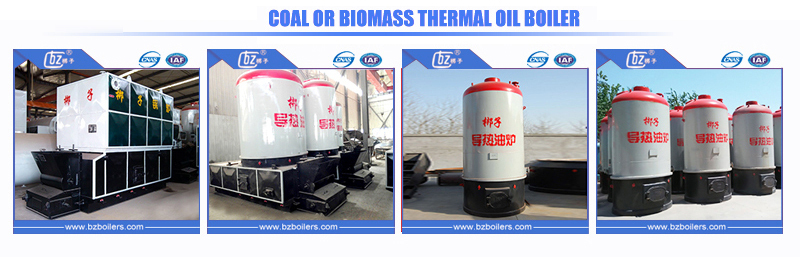

ISO standard Coal fired oil heat boiler for coal chemical industry  ISO standard Coal fired oil heat boiler for coal chemical industry : 1.The heating surface adopts the closely-arranged coils so as to lay out enough heating area,reducr the thermal load on the coil syrface and ensure the safer usage of the heat transfer oils. 2.The ceiling coil on the top of the radiant heating surface can protect the fyrnace top better and prevent it from being burned out. 3.The exhaust gas outlet is positioned right abpve the boiler,which casn balance the heating surface and rationalize the structure. 4.With the rational medium procedure,the heat conducting oil boiler from the low position and flows out of it from the high position.In this way,the gas produced during the operation can be discharged out of boiler smoothly. 5.It is very convenient to install the boil because we only need to pot the upper boday and the below combustor together.So the installation period is very short. Technical parameters of oil heat boiler

ISO standard Coal fired oil heat boiler for coal chemical industry : 1.The heating surface adopts the closely-arranged coils so as to lay out enough heating area,reducr the thermal load on the coil syrface and ensure the safer usage of the heat transfer oils. 2.The ceiling coil on the top of the radiant heating surface can protect the fyrnace top better and prevent it from being burned out. 3.The exhaust gas outlet is positioned right abpve the boiler,which casn balance the heating surface and rationalize the structure. 4.With the rational medium procedure,the heat conducting oil boiler from the low position and flows out of it from the high position.In this way,the gas produced during the operation can be discharged out of boiler smoothly. 5.It is very convenient to install the boil because we only need to pot the upper boday and the below combustor together.So the installation period is very short. Technical parameters of oil heat boiler

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.  Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.  Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.

Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.  FAQ Q1: How to install a boiler? A1: Bangzi Boiler provides completed installation drawing and manual, or send engineer abroad for installation guidance Q2:How many years is the boiler’s life span A2: The boiler is designed for 10years life span, but under good maintenance, usually the boiler can use at least 16years, Bangzi Boiler provide full life after-sales service to each sold boiler Q3: How to choose a boiler model? A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, BangziBoiler will suggest a suitable model based on your usage. Q4: How is the warranty term? A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client’s side, the Seller will help supply the spare part at lowest cost. Contact

FAQ Q1: How to install a boiler? A1: Bangzi Boiler provides completed installation drawing and manual, or send engineer abroad for installation guidance Q2:How many years is the boiler’s life span A2: The boiler is designed for 10years life span, but under good maintenance, usually the boiler can use at least 16years, Bangzi Boiler provide full life after-sales service to each sold boiler Q3: How to choose a boiler model? A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, BangziBoiler will suggest a suitable model based on your usage. Q4: How is the warranty term? A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client’s side, the Seller will help supply the spare part at lowest cost. Contact

ISO standard Coal fired oil heat boiler for coal chemical industry : 1.The heating surface adopts the closely-arranged coils so as to lay out enough heating area,reducr the thermal load on the coil syrface and ensure the safer usage of the heat transfer oils. 2.The ceiling coil on the top of the radiant heating surface can protect the fyrnace top better and prevent it from being burned out. 3.The exhaust gas outlet is positioned right abpve the boiler,which casn balance the heating surface and rationalize the structure. 4.With the rational medium procedure,the heat conducting oil boiler from the low position and flows out of it from the high position.In this way,the gas produced during the operation can be discharged out of boiler smoothly. 5.It is very convenient to install the boil because we only need to pot the upper boday and the below combustor together.So the installation period is very short. Technical parameters of oil heat boiler

ISO standard Coal fired oil heat boiler for coal chemical industry : 1.The heating surface adopts the closely-arranged coils so as to lay out enough heating area,reducr the thermal load on the coil syrface and ensure the safer usage of the heat transfer oils. 2.The ceiling coil on the top of the radiant heating surface can protect the fyrnace top better and prevent it from being burned out. 3.The exhaust gas outlet is positioned right abpve the boiler,which casn balance the heating surface and rationalize the structure. 4.With the rational medium procedure,the heat conducting oil boiler from the low position and flows out of it from the high position.In this way,the gas produced during the operation can be discharged out of boiler smoothly. 5.It is very convenient to install the boil because we only need to pot the upper boday and the below combustor together.So the installation period is very short. Technical parameters of oil heat boiler | projects | units | YLW-700 | YLW-1000 | YLW-1200 | YLW-1400 | YLW-2000 | YLW-2400 | YLW-2900 | YLW-3500 | YLW-4700 | YLW-6000 | YLW-7000 | YLW-10000 | YLW-18000 |

| rated thermal power | kw | 700 | 1000 | 1200 | 1400 | 2000 | 2400 | 2900 | 3500 | 4700 | 6000 | 7000 | 10000 | 18000 |

| rated working pressure | MPa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| highest working temperature | ℃ | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| oil volumn in the boiler | cube meters | 0.52 | 0.66 | 0.85 | 1.09 | 1.33 | 1.6 | 2.2 | 2.6 | 3.8 | 4.7 | 5.24 | 6.3 | 12.3 |

| cycle oil volumn | cube meters/h | 60 | 60 | 80 | 100 | 160 | 160 | 180 | 200 | 300 | 360 | 400 | 400 | 1000 |

| pipe diameter | DN | 100 | 125 | 125 | 125 | 150 | 150 | 150 | 200 | 200 | 250 | 250 | 300 | 350 |

| applicable fuel | Coal, biomass, biomass pellets, pellets, wood chips, wood pellets, wood, sawdust, solid fuel... | |||||||||||||

| thermal efficiency | % | more than 76% | more than 78% | more than 79% | more than 80% | |||||||||

| coal consumption | kg/h | 145 | 180 | 220 | 265 | 390 | 465 | 560 | 650 | 890 | 1120 | 1380 | 2200 | 3320 |

| No. | industry | usage |

| 1 | Chemical industry | polymerization industry,oil industry,reaction tank,distillation,enrichment, oil chemical industry, industry, polymerization reaction cans, distillation, concentration |

| 2 | Plastic industry | plastic foam and squeeze to finalize the design, |

| 3 | Textile industry | resin stenters,dyeing machine and the dry room,high temperature machine,roller |

| 4 | Rubber industry | cooking,dry,vegetable oil refining |

| 5 | Wood industry | heating to finalize the design of chipboard,sandwich plate,wamu board,fiber |

| 6 | Paper industry | multi-layer cardboard of packed carton box,dying and desiccation |

| 7 | Others | heating of metal electroplating slot,coating condensation,drying,distillation of pharmaceutical industry,reduction,concentration,dehydration,air conditioning industry,etc |

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.  Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.

Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.  FAQ Q1: How to install a boiler? A1: Bangzi Boiler provides completed installation drawing and manual, or send engineer abroad for installation guidance Q2:How many years is the boiler’s life span A2: The boiler is designed for 10years life span, but under good maintenance, usually the boiler can use at least 16years, Bangzi Boiler provide full life after-sales service to each sold boiler Q3: How to choose a boiler model? A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, BangziBoiler will suggest a suitable model based on your usage. Q4: How is the warranty term? A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client’s side, the Seller will help supply the spare part at lowest cost. Contact

FAQ Q1: How to install a boiler? A1: Bangzi Boiler provides completed installation drawing and manual, or send engineer abroad for installation guidance Q2:How many years is the boiler’s life span A2: The boiler is designed for 10years life span, but under good maintenance, usually the boiler can use at least 16years, Bangzi Boiler provide full life after-sales service to each sold boiler Q3: How to choose a boiler model? A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, BangziBoiler will suggest a suitable model based on your usage. Q4: How is the warranty term? A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client’s side, the Seller will help supply the spare part at lowest cost. Contact

You May Also Like

You May Also Like