polypropylene honeycomb panel

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

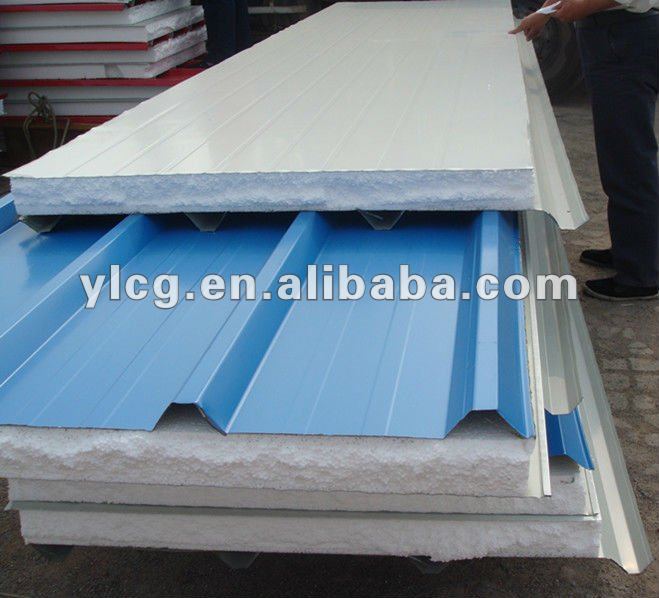

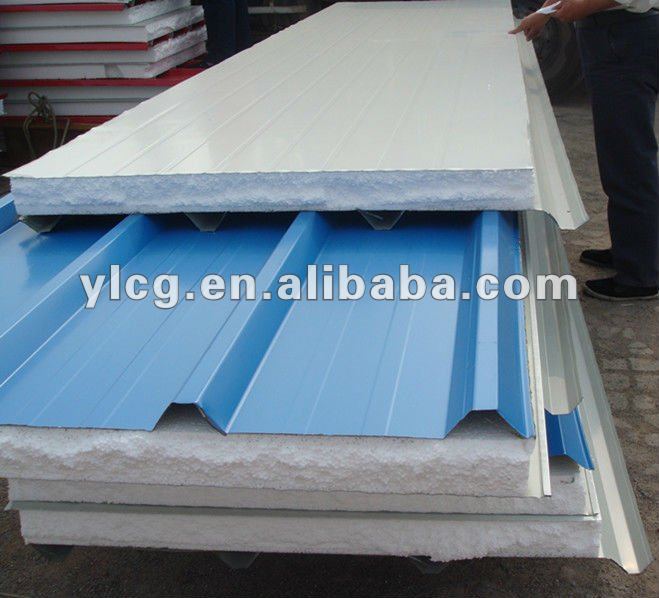

polypropylene honeycomb panel Specifications (1)Good quality ,low cost

(2)Rock wool sandwich panel

(3)Best services

(4)Thermal Insulation,Sound insulation Feature: (1)Our rock wool sandwich panel is fireproof, waterproof and airproof, sound insulation, heat preservation, convenient construction, attractive facade, environment-friendly (2)All panels shall be packed according to various length and width indicted in packing list. Perlite wool shall be put under and above tips of panels. Whose reel perlite shall be adopted if necessary to avoid scratch. The foam above each panel pr each bundle of panels shall be marked with length. (3)Our Vertical slab closing side has special N-couplers,it is waterproof and airproof and easy to installate. (4)Rock wool sandwich panel involve many fields in railway-aviation industry, automotive industry, electronic industry, power plants, chemical industry, cosmetics industry, pharmaceutical industry, food industry, logistics, real estate, sports stadiums, convention centers and other industrial, civil construction. (5)Freedom to choose External steel and rock wool ,we meet costemers’s any requires

waterproof heatinsulation colorfast reliable quality durable in use reliable reputation finely processed sophisticated technolog Typical applications are industrial and commercial buildings, sports facilities, warehouses and power plants. The panel is also suitable for use in construction for

the food industry and for demanding clean room applications.

(2)Rock wool sandwich panel

(3)Best services

(4)Thermal Insulation,Sound insulation Feature: (1)Our rock wool sandwich panel is fireproof, waterproof and airproof, sound insulation, heat preservation, convenient construction, attractive facade, environment-friendly (2)All panels shall be packed according to various length and width indicted in packing list. Perlite wool shall be put under and above tips of panels. Whose reel perlite shall be adopted if necessary to avoid scratch. The foam above each panel pr each bundle of panels shall be marked with length. (3)Our Vertical slab closing side has special N-couplers,it is waterproof and airproof and easy to installate. (4)Rock wool sandwich panel involve many fields in railway-aviation industry, automotive industry, electronic industry, power plants, chemical industry, cosmetics industry, pharmaceutical industry, food industry, logistics, real estate, sports stadiums, convention centers and other industrial, civil construction. (5)Freedom to choose External steel and rock wool ,we meet costemers’s any requires

| Effective width | Wall panel: 950mm 1150mm 1200mm |

| Length | According to customer's request |

| Materials | Polystyrene foam board(EPS), Color steel sheet |

| Structure | Upper and lower layer: Color steel sheet Middle: polystyrene foam board or polyurethane foam board |

| Thickness | Color steel sheet: 0.3-0.6mm Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm |

| The polystyrene density | 8-20kg/m3 |

| Conventional color | Ocean blue, tephrosious, or as customer required |

| character | Light in weight, heat insulation, water resistant, green and environmental |

| Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

the food industry and for demanding clean room applications.

Related Keywords

Related Keywords