DX-12.0III-DX 12.48CBM HF type vacuum chamber drying timber from China

- Delivery Time:

- 25 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

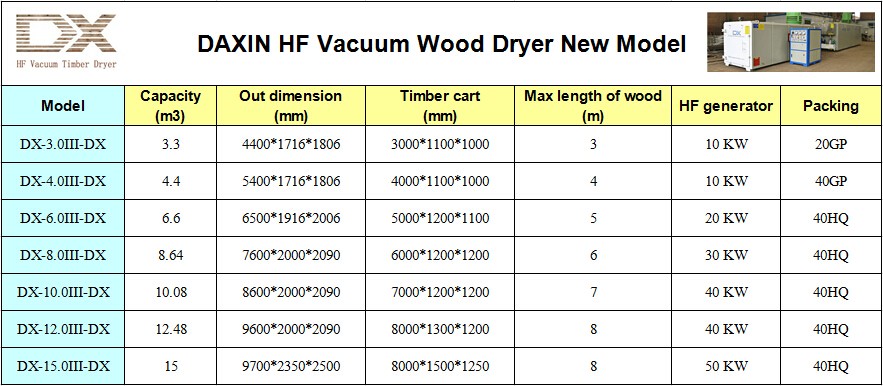

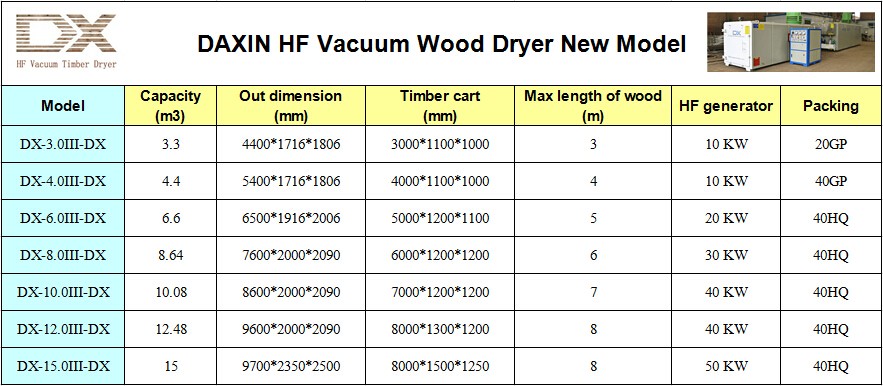

DX-12.0III-DX 12.48CBM HF type vacuum chamber drying timber from China Product Description Daxin Electronic Science And Technology Co., Ltd. is one of the leading manufacture factory of high frequency vacuum wood drying equipment and high frequency generator in Hebei Province,China. In this industry more than 20 years.we have the patent certification and CE certification . It is the newest drying technology in woodworking machinery industry. We can supply capacity 3cbm, 4cbm, 6cbm, 8cbm, 10cbm, 15cbm, 20cbm. It sold in Japan, Thailand, Vietnam, USA, UK, Canada, Uganda, New Zealand, Bulgaria, Iran, Indonesia, Tanzania, Austria etc. Now very popular drying technology in China. Three main parts of HF vacuum wood dryer machine: High strength steel structural vacuum square oven High frequency generator Cooling tower

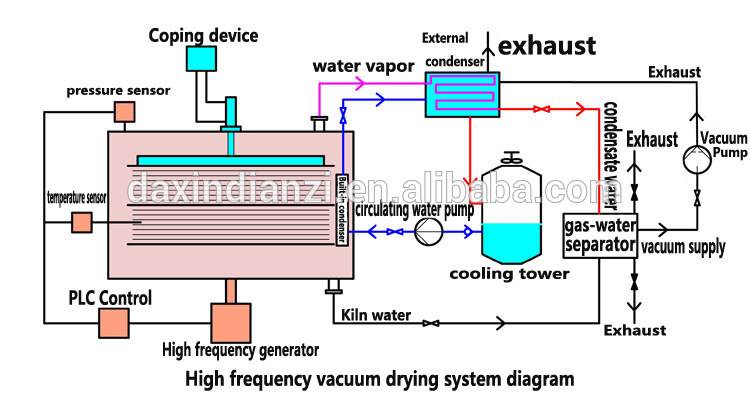

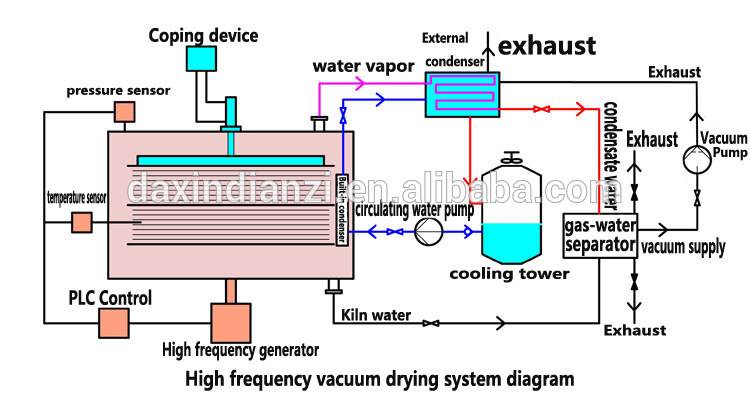

HF Timber dryer adopts high frequency drying, inside and outside of wood timber is heated at same time, uniform heating, high speed drying, short time and good quality, which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard precious wood, wet wood. Drying eucalyptus timbers from wet of saw to a final mositure content of about 8-12%. HF generator is the core of dielectric heating equipment. It applies three phase alternating current to form frequency oscillation electric field .Under this high frequency electric field, the molecules like water .glue or PVC will be polarized and form two poles. The electric field will change pole rapidly meanwhile all the molecules will also move in very high speed. The friction and impact among molecules can make material get heated in short time. Then the water will be vaporized, glue becomes solid and PVC gets softened rapidly.

HF Timber dryer adopts high frequency drying, inside and outside of wood timber is heated at same time, uniform heating, high speed drying, short time and good quality, which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard precious wood, wet wood. Drying eucalyptus timbers from wet of saw to a final mositure content of about 8-12%. HF generator is the core of dielectric heating equipment. It applies three phase alternating current to form frequency oscillation electric field .Under this high frequency electric field, the molecules like water .glue or PVC will be polarized and form two poles. The electric field will change pole rapidly meanwhile all the molecules will also move in very high speed. The friction and impact among molecules can make material get heated in short time. Then the water will be vaporized, glue becomes solid and PVC gets softened rapidly.  Product and User Show Using steps (Full-auto working system)

Product and User Show Using steps (Full-auto working system)  After-drying quality(Mahogany from 50% to 10% with good effect)

After-drying quality(Mahogany from 50% to 10% with good effect)  Other wood drying (Teak, Beech, Black walnut...)

Other wood drying (Teak, Beech, Black walnut...)

Packaging & Shipping This is one of our HF Vacuum Wood Drying Mchine Exported to the Indonesia, Loaded by 40HQ.

Packaging & Shipping This is one of our HF Vacuum Wood Drying Mchine Exported to the Indonesia, Loaded by 40HQ.

Certificates (ISO/NATIONAL PATENT/CE APPROVAL)

Certificates (ISO/NATIONAL PATENT/CE APPROVAL)  FAQ Why we choose HIGH FREQUENCY VACUUM? 1)Heating fast and uniformly, fast drying;(more than10 times faster than conventional steam dryer); 2)Saving labor, cost and drying time; 3)Full-automatic, easy to control and operate; flexible and simple; 4)High outturn percentage, no crack, no deformation; 5)Environmental protection; 6)New square design tank increase the availability of the inner space; 7)Bacteria and worm killing, high outturn percentage ; 8)Drying apply for all kinds of wood Thank you for visiting our website, pls contact with us freely!

FAQ Why we choose HIGH FREQUENCY VACUUM? 1)Heating fast and uniformly, fast drying;(more than10 times faster than conventional steam dryer); 2)Saving labor, cost and drying time; 3)Full-automatic, easy to control and operate; flexible and simple; 4)High outturn percentage, no crack, no deformation; 5)Environmental protection; 6)New square design tank increase the availability of the inner space; 7)Bacteria and worm killing, high outturn percentage ; 8)Drying apply for all kinds of wood Thank you for visiting our website, pls contact with us freely!

HF Timber dryer adopts high frequency drying, inside and outside of wood timber is heated at same time, uniform heating, high speed drying, short time and good quality, which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard precious wood, wet wood. Drying eucalyptus timbers from wet of saw to a final mositure content of about 8-12%. HF generator is the core of dielectric heating equipment. It applies three phase alternating current to form frequency oscillation electric field .Under this high frequency electric field, the molecules like water .glue or PVC will be polarized and form two poles. The electric field will change pole rapidly meanwhile all the molecules will also move in very high speed. The friction and impact among molecules can make material get heated in short time. Then the water will be vaporized, glue becomes solid and PVC gets softened rapidly.

HF Timber dryer adopts high frequency drying, inside and outside of wood timber is heated at same time, uniform heating, high speed drying, short time and good quality, which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard precious wood, wet wood. Drying eucalyptus timbers from wet of saw to a final mositure content of about 8-12%. HF generator is the core of dielectric heating equipment. It applies three phase alternating current to form frequency oscillation electric field .Under this high frequency electric field, the molecules like water .glue or PVC will be polarized and form two poles. The electric field will change pole rapidly meanwhile all the molecules will also move in very high speed. The friction and impact among molecules can make material get heated in short time. Then the water will be vaporized, glue becomes solid and PVC gets softened rapidly.  Product and User Show Using steps (Full-auto working system)

Product and User Show Using steps (Full-auto working system)  After-drying quality(Mahogany from 50% to 10% with good effect)

After-drying quality(Mahogany from 50% to 10% with good effect)  Other wood drying (Teak, Beech, Black walnut...)

Other wood drying (Teak, Beech, Black walnut...)

Packaging & Shipping This is one of our HF Vacuum Wood Drying Mchine Exported to the Indonesia, Loaded by 40HQ.

Packaging & Shipping This is one of our HF Vacuum Wood Drying Mchine Exported to the Indonesia, Loaded by 40HQ.

Certificates (ISO/NATIONAL PATENT/CE APPROVAL)

Certificates (ISO/NATIONAL PATENT/CE APPROVAL)  FAQ Why we choose HIGH FREQUENCY VACUUM? 1)Heating fast and uniformly, fast drying;(more than10 times faster than conventional steam dryer); 2)Saving labor, cost and drying time; 3)Full-automatic, easy to control and operate; flexible and simple; 4)High outturn percentage, no crack, no deformation; 5)Environmental protection; 6)New square design tank increase the availability of the inner space; 7)Bacteria and worm killing, high outturn percentage ; 8)Drying apply for all kinds of wood Thank you for visiting our website, pls contact with us freely!

FAQ Why we choose HIGH FREQUENCY VACUUM? 1)Heating fast and uniformly, fast drying;(more than10 times faster than conventional steam dryer); 2)Saving labor, cost and drying time; 3)Full-automatic, easy to control and operate; flexible and simple; 4)High outturn percentage, no crack, no deformation; 5)Environmental protection; 6)New square design tank increase the availability of the inner space; 7)Bacteria and worm killing, high outturn percentage ; 8)Drying apply for all kinds of wood Thank you for visiting our website, pls contact with us freely!

Related Keywords

Related Keywords

You May Also Like

You May Also Like