China Factory Reasonable Price HF Vacuum Hard Wood Drying Machines

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Company Information China Factory Reasonable Price HF Vacuum Hard Wood Drying Machines China haibo international co.,ltd/shijaizhuang daxin electronic scince and technology co.,lit is a industry and trade integration company which mainly works on development and manufacture of set of high frequency vacuum drying equipment. Product Description 1.Technolog parameter

Note : The oscillation power is theoretic , actually it needn't so big power . For example 3cbm and4cbm the power are 10KW but actual application of power max need 5kw per hr usually use 4 kw and 3kw per hr for 3cbm and 4cbm . The machine don't work 24 hours for a drying process for per day.

As my machine work principle is when the temperature arrived the temperature's opper limit it will keep constant temperature to standby state.Always like this circulation untill arrived final moisture.

So if drying process for the soft wood total need 3day but have 1.5 days need electricity power another 1.5day is keep constant temperature state . 2. Working flow Our machinei is working in customer's factory !

Our machinei is working in customer's factory !

3.Main component of vacuum oven drying process (1)High strength structure oven body This makes the whole machine stronger and more leak-proof of vacuum.

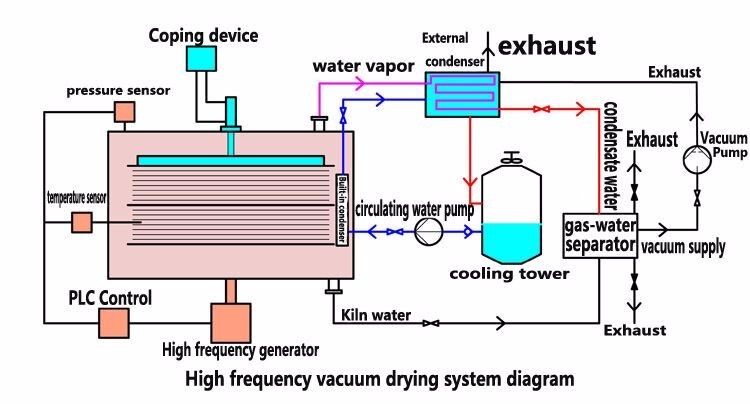

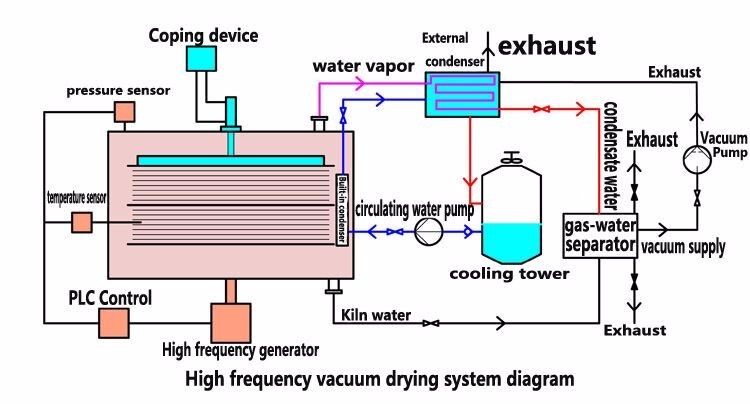

3.Main component of vacuum oven drying process (1)High strength structure oven body This makes the whole machine stronger and more leak-proof of vacuum.  (2) High frequency generator This is the core of this machine, all procedures and main technology are inside, Including PLC,electric valve etc.

(2) High frequency generator This is the core of this machine, all procedures and main technology are inside, Including PLC,electric valve etc.

(3)Cooling tower This part is mainly used in hot weather, the main usage is to cool the internal temperature, guarantee the drying speed and quality.

(3)Cooling tower This part is mainly used in hot weather, the main usage is to cool the internal temperature, guarantee the drying speed and quality.  (4)Timber cart We have both full-auto feeding mode and manual feeding model, but the full-auto is only used on 8/10/12/15cbm models, because the smaller doesn’t need this, the loading quantity is enough to be push into the oven by workers.

(4)Timber cart We have both full-auto feeding mode and manual feeding model, but the full-auto is only used on 8/10/12/15cbm models, because the smaller doesn’t need this, the loading quantity is enough to be push into the oven by workers.  (5)Stainless condenser This parts are also to reduce the internal temperature when drying, it will let the steam change into water droplet, to guarantee the drying speed and quality.

(5)Stainless condenser This parts are also to reduce the internal temperature when drying, it will let the steam change into water droplet, to guarantee the drying speed and quality.  (6)Pressure system We have both hydraulic and pneumatic, that means common oil pressure system and air pressure system, they are to prevent the wood becoming bend and crack.

(6)Pressure system We have both hydraulic and pneumatic, that means common oil pressure system and air pressure system, they are to prevent the wood becoming bend and crack.  (7)Perforated aluminum plate and wooden bar These two parts are to separate wood to dissipating heat quickly, guarantee the drying speed.

(7)Perforated aluminum plate and wooden bar These two parts are to separate wood to dissipating heat quickly, guarantee the drying speed.  (8)Final moisture

(8)Final moisture  Our Services Warranty: 1 year for the whole machine. After-sale service: Engineers available to service machinery overseas. If there were some parts broken by itself, we can supply the parts freely within 1 year. Our customers come from different countries,we warmly welcome you to visit our factory !

Our Services Warranty: 1 year for the whole machine. After-sale service: Engineers available to service machinery overseas. If there were some parts broken by itself, we can supply the parts freely within 1 year. Our customers come from different countries,we warmly welcome you to visit our factory !  Packaging & Shipping As usually we adpot standard export packing, plastic and foam, fixed by wood pallet, shipped in container by sea! we can also packing the machine according to your requirements .

Packaging & Shipping As usually we adpot standard export packing, plastic and foam, fixed by wood pallet, shipped in container by sea! we can also packing the machine according to your requirements .  Certifications

Certifications  If you have any other questions , please feel free to contact with me in any time ! Ellen Liu

If you have any other questions , please feel free to contact with me in any time ! Ellen Liu

China Haibo International Co.,Ltd

SKYPE:vhaibo9

MOB/whatsapp:86-13722980382

TEL:+86-0311-89836929 FAX:+86-0311-86682328

WEB:![]() www.hfwoodmachine.com

www.hfwoodmachine.com

| Model | DX-3.0lll-DX | DX-4.0lll-DX | DX-6.0lll-DX | DX-8.0lll-DX | DX-10.0lll-DX | DX-12.0lll-DX |

| Capacity(CBM) | 3.3 | 4.4 | 6.6 | 8.64 | 10.08 | 14.04 |

| Out Dimension (mm) | 4400*1716*1806 | 5400*1716*1806 | 6500*1916*2006 | 7600*2000*2090 | 8600*2000*2090 | 9600*2000* 2090 |

| Inside Dimension(mm) | 3600*1500*1500 | 4600*1500*1500 | 5700*1700*1700 | 6800*1750*1750 | 7800*1750*1750 | 8800*1750* 1750 |

| Timer cart (mm) | 3000*1100*1000 | 4000*1100*1000 | 5000*1200*1100 | 6000*1200*1200 | 7000*1200*1200 | 8000*1300* 1200 |

| Max Length of Wood | 3m | 4m | 5m | 6m | 7m | 8m |

| High frequency | 6.78MHz | |||||

| Input Power | 15KVA | 15KVA | 30KVA | 40KVA | 50KVA | 50KVA |

| Oscillation Power | 10KW | 10KW | 20KW | 30KW | 40KW | 40KW |

| Vacuum pressure | -0.093MPa | |||||

| Weight | 4000kg | 5000kg | 7000kg | 9000kg | 11000kg | 13000kg |

| Packing | 20GP | 40GP | 40HQ | 40HQ | 40HQ | 40HQ |

| Vacuum oven Temp | Vacuum oven drying temperature not more 90℃ | |||||

| Moisture | From 90%to 6%, can be setting according to your requirements . | |||||

| Drying time | 2-7 days | |||||

| Application | Apply for all the hardwood piecise | |||||

As my machine work principle is when the temperature arrived the temperature's opper limit it will keep constant temperature to standby state.Always like this circulation untill arrived final moisture.

So if drying process for the soft wood total need 3day but have 1.5 days need electricity power another 1.5day is keep constant temperature state . 2. Working flow

Our machinei is working in customer's factory !

Our machinei is working in customer's factory !

3.Main component of vacuum oven drying process (1)High strength structure oven body This makes the whole machine stronger and more leak-proof of vacuum.

3.Main component of vacuum oven drying process (1)High strength structure oven body This makes the whole machine stronger and more leak-proof of vacuum.  (2) High frequency generator This is the core of this machine, all procedures and main technology are inside, Including PLC,electric valve etc.

(2) High frequency generator This is the core of this machine, all procedures and main technology are inside, Including PLC,electric valve etc.

(3)Cooling tower This part is mainly used in hot weather, the main usage is to cool the internal temperature, guarantee the drying speed and quality.

(3)Cooling tower This part is mainly used in hot weather, the main usage is to cool the internal temperature, guarantee the drying speed and quality.  (4)Timber cart We have both full-auto feeding mode and manual feeding model, but the full-auto is only used on 8/10/12/15cbm models, because the smaller doesn’t need this, the loading quantity is enough to be push into the oven by workers.

(4)Timber cart We have both full-auto feeding mode and manual feeding model, but the full-auto is only used on 8/10/12/15cbm models, because the smaller doesn’t need this, the loading quantity is enough to be push into the oven by workers.  (5)Stainless condenser This parts are also to reduce the internal temperature when drying, it will let the steam change into water droplet, to guarantee the drying speed and quality.

(5)Stainless condenser This parts are also to reduce the internal temperature when drying, it will let the steam change into water droplet, to guarantee the drying speed and quality.  (6)Pressure system We have both hydraulic and pneumatic, that means common oil pressure system and air pressure system, they are to prevent the wood becoming bend and crack.

(6)Pressure system We have both hydraulic and pneumatic, that means common oil pressure system and air pressure system, they are to prevent the wood becoming bend and crack.  (7)Perforated aluminum plate and wooden bar These two parts are to separate wood to dissipating heat quickly, guarantee the drying speed.

(7)Perforated aluminum plate and wooden bar These two parts are to separate wood to dissipating heat quickly, guarantee the drying speed.  (8)Final moisture

(8)Final moisture  Our Services Warranty: 1 year for the whole machine. After-sale service: Engineers available to service machinery overseas. If there were some parts broken by itself, we can supply the parts freely within 1 year. Our customers come from different countries,we warmly welcome you to visit our factory !

Our Services Warranty: 1 year for the whole machine. After-sale service: Engineers available to service machinery overseas. If there were some parts broken by itself, we can supply the parts freely within 1 year. Our customers come from different countries,we warmly welcome you to visit our factory !  Packaging & Shipping As usually we adpot standard export packing, plastic and foam, fixed by wood pallet, shipped in container by sea! we can also packing the machine according to your requirements .

Packaging & Shipping As usually we adpot standard export packing, plastic and foam, fixed by wood pallet, shipped in container by sea! we can also packing the machine according to your requirements .  Certifications

Certifications  If you have any other questions , please feel free to contact with me in any time ! Ellen Liu

If you have any other questions , please feel free to contact with me in any time ! Ellen Liu China Haibo International Co.,Ltd

SKYPE:vhaibo9

MOB/whatsapp:86-13722980382

TEL:+86-0311-89836929 FAX:+86-0311-86682328

WEB:

Related Keywords

Related Keywords

You May Also Like

You May Also Like