China Professional Manufacturer HF Vacuum Hard Lumber Drying Machine For Drying Wood Fast

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Product Description HF Vacuum Hardwood Drying Machinery For Drying Various Wood Fast Factory

The HF vacuum wood drying machine is result of design combining high frequency medium heating technology and vacuum cryogenic dehydration technology,greatly reduced drying time and avoid high temperature damage of wood. It apply to all the kinds wood, such as oak ,verawood ,rose wood , the moisture can be reduced from 60% to 8% even 6%, only need to 3- 7 days each batch.

Main Features 1) Fast speed and high efficiency When HF starts,the molecules in the dielectric material will be polarized in very short time and heated.HF power only heat polar molecules.It will not heat dielectric material.HF heating is 3-5 times faster than hot steam.So it can save the power and improve the efficiency.

Main Features 1) Fast speed and high efficiency When HF starts,the molecules in the dielectric material will be polarized in very short time and heated.HF power only heat polar molecules.It will not heat dielectric material.HF heating is 3-5 times faster than hot steam.So it can save the power and improve the efficiency.

2) Uniform heating High frequency heating is dielectric heating.It forms electric filed with positive and negative pole.HF power can penetrate material deeply.The waster or glue molecules in the material will get heated themselves by friction among molecules.In this way,they get heated from the core material,much more uniformly.

3) Good applicability High frequency heating can heat kinds of thickness material,such as 2-3mm venner surface lamination,1000mm thick engineered wood gluing.And different frquency can meet different material requirement.13.56MHZ is suitable for PVC heating and gluing 27.12MHZ is good for line production . 4) Strong controllability High frequency heating is easy control and suitable for automatic production.Take HF edge gluer for example,HF can equip well with hydraulic system,electrical system can finish the whole process together.It can also well cooperate with last procedure.

5) No damage of wood In the vacuum environment, moisture can evaporate at lower temperatures ,so vacuum cryogenic dehydration technology avoid high temperature to damage wood .

6)Envirnoment friendly HF heating doesn't need boiler.There is no dust,no fog,no pollution.DAXIN's products accord with national standard of radiation.

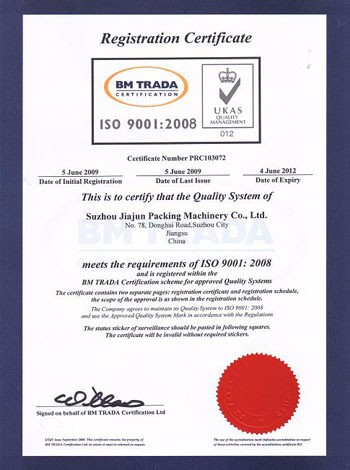

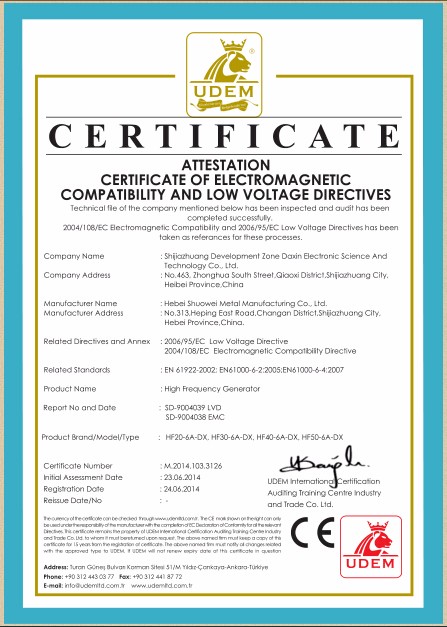

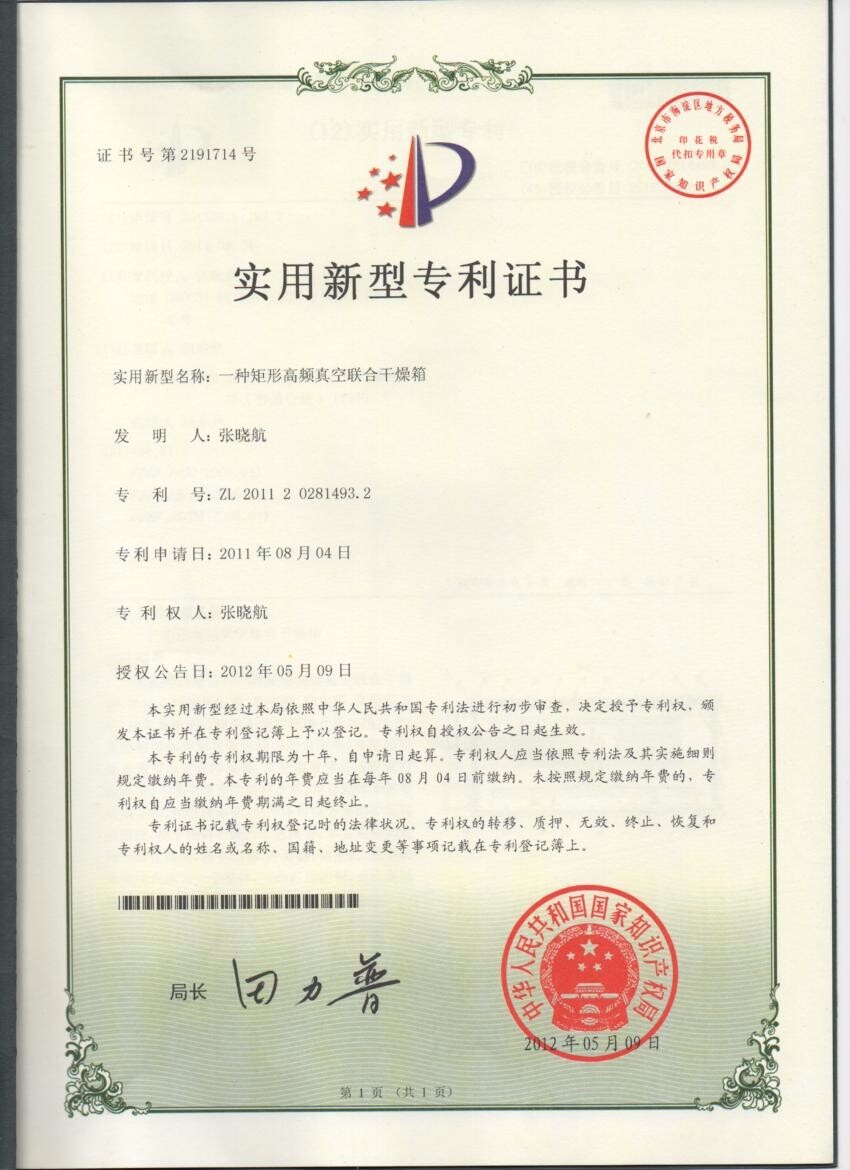

Certifications

Details show

Details show  1.High strength steel structural oven body.

1.High strength steel structural oven body.

This makes the whole machine stronger and more

leak-proof of vacuum.

2.High frequency generator

This is the core of this machine, all procedures and main technology are inside,including PLC,electric valve etc.

3.Cooling tower This part is mainly used in hot weather, the main usage is to cool the internal temperature, guarantee the drying speed and quality.

3.Cooling tower This part is mainly used in hot weather, the main usage is to cool the internal temperature, guarantee the drying speed and quality.

4.Timber cart We have both full-auto feeding mode and manual feeding model, but the full-auto is only used on 8/10/12/15cbm models, because the smaller doesn’t need this, the

4.Timber cart We have both full-auto feeding mode and manual feeding model, but the full-auto is only used on 8/10/12/15cbm models, because the smaller doesn’t need this, the

loading quantity is enough to be push into the oven by workers.

5.Stainless condenser

This parts are also to reduce the internal temperature when drying, it will let the steam change into water droplet, to guarantee the drying speed and quality.

6.Pressure system

6.Pressure system

We have both hydraulic and pneumatic, that means common oil pressure system and air pressure system, they are to prevent the wood becoming bend and crack.

7.Perforated aluminum plate ,copper strip and wooden bar. Aluminum plade and copper form electric field, to speed up the electronic movement and enhance the heating rate.

These two parts are to separate wood to dissipating heat quickly, guarantee the drying speed.

Our Service

Our Service

Pre-Sales Service

Pre-Sales Service

* Inquiry and consulting support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training

how to use the machine.

* Engineers available to service machinery overseas. Professional team & Professional service .We have professional sale team and engineers , we can offer the professional , the best service according to our

experience. Packing & Delivery

Standard export packing, plastic and foam, fixed by wood pallet, shipped in container by sea .

Good results

Moisture measurement Moisture reduced to 6.6%.

Moisture measurement Moisture reduced to 6.6%.

Dehydration up to 243kg one day

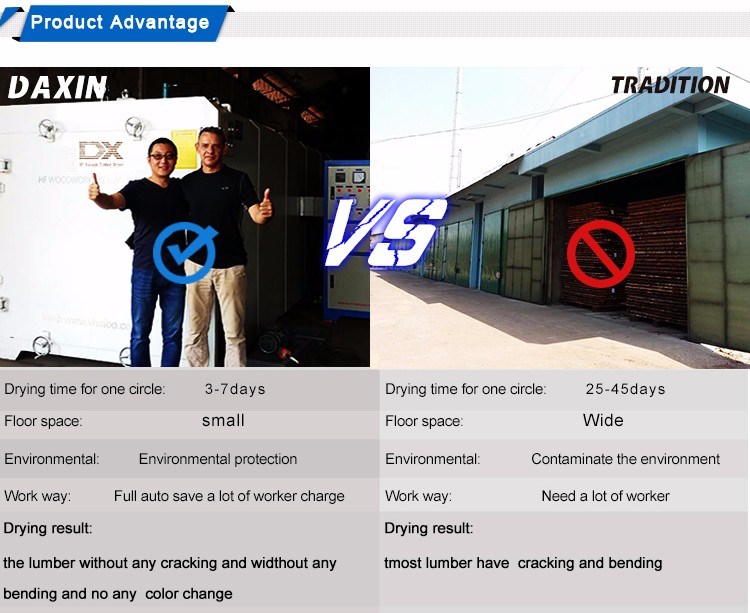

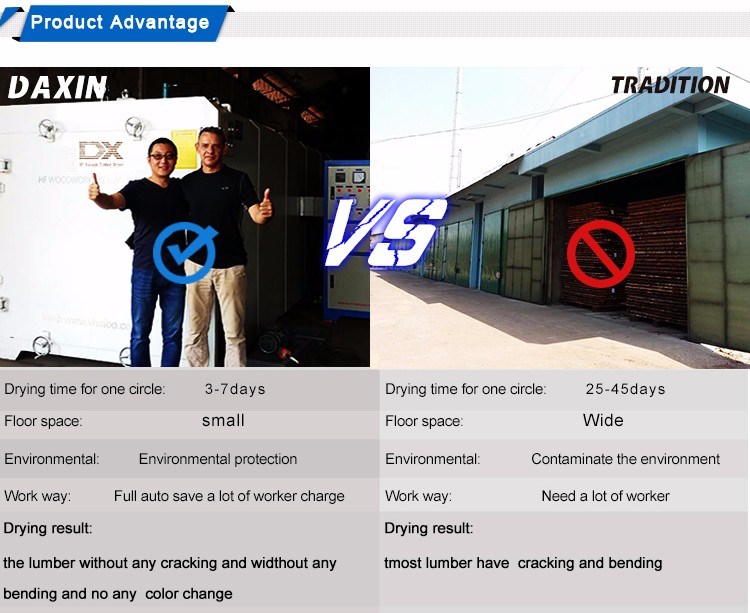

Comparative Contact me Miss.Ellen

Contact me Miss.Ellen

SKYPE: vhaibo9

MOB/Whatsapp: 0086-13722980382

TEL:+86-0311-89836929 FAX:+86-0311-86682328

China Haibo International Co.,Ltd

Web: www.hfwoodmachine.com

The HF vacuum wood drying machine is result of design combining high frequency medium heating technology and vacuum cryogenic dehydration technology,greatly reduced drying time and avoid high temperature damage of wood. It apply to all the kinds wood, such as oak ,verawood ,rose wood , the moisture can be reduced from 60% to 8% even 6%, only need to 3- 7 days each batch.

Main Features 1) Fast speed and high efficiency When HF starts,the molecules in the dielectric material will be polarized in very short time and heated.HF power only heat polar molecules.It will not heat dielectric material.HF heating is 3-5 times faster than hot steam.So it can save the power and improve the efficiency.

Main Features 1) Fast speed and high efficiency When HF starts,the molecules in the dielectric material will be polarized in very short time and heated.HF power only heat polar molecules.It will not heat dielectric material.HF heating is 3-5 times faster than hot steam.So it can save the power and improve the efficiency.2) Uniform heating High frequency heating is dielectric heating.It forms electric filed with positive and negative pole.HF power can penetrate material deeply.The waster or glue molecules in the material will get heated themselves by friction among molecules.In this way,they get heated from the core material,much more uniformly.

3) Good applicability High frequency heating can heat kinds of thickness material,such as 2-3mm venner surface lamination,1000mm thick engineered wood gluing.And different frquency can meet different material requirement.13.56MHZ is suitable for PVC heating and gluing 27.12MHZ is good for line production . 4) Strong controllability High frequency heating is easy control and suitable for automatic production.Take HF edge gluer for example,HF can equip well with hydraulic system,electrical system can finish the whole process together.It can also well cooperate with last procedure.

5) No damage of wood In the vacuum environment, moisture can evaporate at lower temperatures ,so vacuum cryogenic dehydration technology avoid high temperature to damage wood .

6)Envirnoment friendly HF heating doesn't need boiler.There is no dust,no fog,no pollution.DAXIN's products accord with national standard of radiation.

Certifications

Details show

Details show  1.High strength steel structural oven body.

1.High strength steel structural oven body. This makes the whole machine stronger and more

leak-proof of vacuum.

2.High frequency generator

This is the core of this machine, all procedures and main technology are inside,including PLC,electric valve etc.

3.Cooling tower This part is mainly used in hot weather, the main usage is to cool the internal temperature, guarantee the drying speed and quality.

3.Cooling tower This part is mainly used in hot weather, the main usage is to cool the internal temperature, guarantee the drying speed and quality.  4.Timber cart We have both full-auto feeding mode and manual feeding model, but the full-auto is only used on 8/10/12/15cbm models, because the smaller doesn’t need this, the

4.Timber cart We have both full-auto feeding mode and manual feeding model, but the full-auto is only used on 8/10/12/15cbm models, because the smaller doesn’t need this, theloading quantity is enough to be push into the oven by workers.

5.Stainless condenser

This parts are also to reduce the internal temperature when drying, it will let the steam change into water droplet, to guarantee the drying speed and quality.

6.Pressure system

6.Pressure systemWe have both hydraulic and pneumatic, that means common oil pressure system and air pressure system, they are to prevent the wood becoming bend and crack.

7.Perforated aluminum plate ,copper strip and wooden bar. Aluminum plade and copper form electric field, to speed up the electronic movement and enhance the heating rate.

These two parts are to separate wood to dissipating heat quickly, guarantee the drying speed.

Our Service

Our Service

Pre-Sales Service

Pre-Sales Service* Inquiry and consulting support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training

how to use the machine.

* Engineers available to service machinery overseas. Professional team & Professional service .We have professional sale team and engineers , we can offer the professional , the best service according to our

experience. Packing & Delivery

Standard export packing, plastic and foam, fixed by wood pallet, shipped in container by sea .

Good results

Moisture measurement Moisture reduced to 6.6%.

Moisture measurement Moisture reduced to 6.6%. Dehydration up to 243kg one day

Comparative

Contact me Miss.Ellen

Contact me Miss.Ellen SKYPE: vhaibo9

MOB/Whatsapp: 0086-13722980382

TEL:+86-0311-89836929 FAX:+86-0311-86682328

China Haibo International Co.,Ltd

Web: www.hfwoodmachine.com

Related Keywords

Related Keywords

You May Also Like

You May Also Like