Automatic Welding Carriages in Arc welders

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Specifications Automatic Welding Carriages in Arc welders

Modular construction to make dismounting easily ,meeting the actual requirements

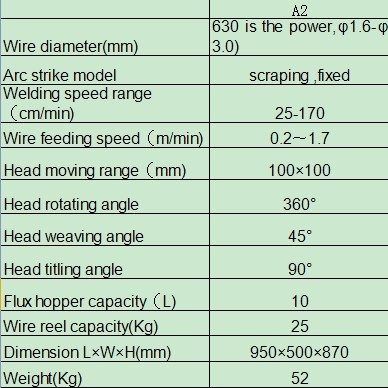

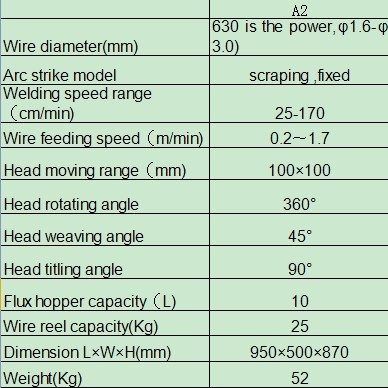

Automatic Welding Carriages in Arc welders Special design for thick wire SAW,suitable for 3-5 wire and applicable to power source MZ-1000/1250 Characteristics 1 Modular construction to make dismounting easily ,meeting the actual requirements from various customers. 2 With four-wheel driving to realized stable moving .Six degree of freedom regulation meets any position request. 3 Combined wire feeding wheel improves using life and production efficiency. 4 Be suitable for welding carbon steel, stainless steel,copper and copper alloy. 5 Wire feeding unit adopts planetary reducer to make large moment and high stability. 6 Wire straighting unit keep the wire in good state. 7 Welding torch conduction adopts eccentric design,which realizes a strong conductivity. About welding control box Control box:simple circuit and easy maintenance.SCR speed-adjusting circuit is available in motor. Power source:applicable to MZ series SAW power source. About cable From power source to welding head:15m(extending to 50m) From power source to welding head:4m(extending to 50m) Main Technical Parameter

For further relevant product images or details,please contact us:

For further relevant product images or details,please contact us:

Modular construction to make dismounting easily ,meeting the actual requirements

Automatic Welding Carriages in Arc welders Special design for thick wire SAW,suitable for 3-5 wire and applicable to power source MZ-1000/1250 Characteristics 1 Modular construction to make dismounting easily ,meeting the actual requirements from various customers. 2 With four-wheel driving to realized stable moving .Six degree of freedom regulation meets any position request. 3 Combined wire feeding wheel improves using life and production efficiency. 4 Be suitable for welding carbon steel, stainless steel,copper and copper alloy. 5 Wire feeding unit adopts planetary reducer to make large moment and high stability. 6 Wire straighting unit keep the wire in good state. 7 Welding torch conduction adopts eccentric design,which realizes a strong conductivity. About welding control box Control box:simple circuit and easy maintenance.SCR speed-adjusting circuit is available in motor. Power source:applicable to MZ series SAW power source. About cable From power source to welding head:15m(extending to 50m) From power source to welding head:4m(extending to 50m) Main Technical Parameter

For further relevant product images or details,please contact us:

For further relevant product images or details,please contact us:

Related Keywords

Related Keywords

You May Also Like

You May Also Like