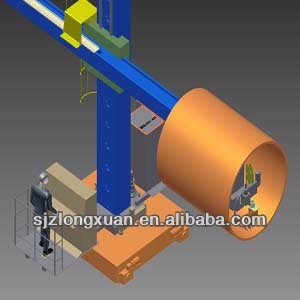

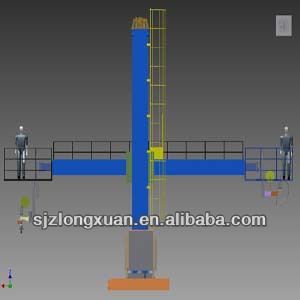

Small Cylinder Welding manipulators with TV Monitor

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

1.Automatic system

2.Easily operate

3.Competitive price

4.Good quality

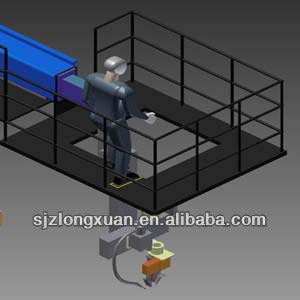

Small Cylinder Welding manipulators with TV Monitor Scope of application The automatic welding center is widely used in pressure vessel,refrigeration plant,power plant,wind tower generatingequipment,aviation,metallurgy industry,engineering plant,watercraft manufacture, roller resurfacing welding,petrochemical industry and so on. Standard configuration The standard collocation includes main frame-fixed type,manual cross-saddle,spuspended welding head, remote-control pendant and standard electrical control system which can control the boom up &down, boom stretching,welding start &stop and linkage of turning rolls and positioner.Adopting trangle guide rail;Inverter control system Selectable Configuration Manual or electric rotation mechanism,manual or pneumatic rotating lock mechanism,manual or electric travelling trolley,outside PLCcontroller,manual or electric cross-saddle,welding seam tracking system,TIG wire feeding device,ALC arc length control unit,submerged arc welding head and controller Product features *The welding center can integrate seam tracking system,video monitoring system,waving system,arc length control system to realize mechanization,atomization,high efficiency,low cost,high quality production. *Both column and boomadopt outstanding steel and section bar by bending and welding processing.The rail metarial is 45# steel by aging,shaping and grinding process to prevent deformation,improve precision andincrease using life. Technology Parameter ( For reference only. ) Main technology parameter of column

Effective lifting range (m) | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

Max. Boom height,A(using trolley & rotary table)(mm) | 3150 | 4150 | 5150 | 6150 | 7150 | 8150 | 9150 |

Min. Boom height (using trolley & rotary table)(mm) | 1150 | 1150 | 1150 | 1150 | 1150 | 1150 | 1150 |

Max. Boom height,B(using trolley & rotary table)((mm) | 2700 | 3700 | 4700 | 5700 | 6700 | 7700 | 8700 |

Min. Boom height (using trolley & rotary table)(mm) | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

Max. Boom height,C(using stationary foot plate)(mm) | 2550 | 3550 | 4550 | 5550 | 6550 | 7550 | 8550 |

Min. Boom height,(using stationary foot plate)(mm) | 550 | 550 | 550 | 550 | 550 | 550 | 550 |

Total height,D(using trolley &rotary table)(mm) | 4600 | 5600 | 6600 | 7600 | 8600 | 9600 | 10600 |

Total height,E(using rotary table)(mm) | 4150 | 5150 | 6150 | 7150 | 8150 | 9150 | 10150 |

Total height,F(using stationary foot plate)(mm) | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 |

Lifting speed(m/min) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

Effective extension range (m) | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

Max. Extension length,G(mm) | 2650 | 3650 | 4650 | 5650 | 6650 | 7650 | 8650 |

Min.Extension length(mm) | 650 | 650 | 650 | 650 | 650 | 650 | 650 |

Max. permissible loads(kg) | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

One end loads(kg) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

Distance from one end ti cross-section,N(mm) | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Cross-sectional diameter,S(mm) | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

Extension speed (m/min) | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 | 0.15-2.5 |

Related Keywords