ASME B16.20 Spiral Wound Gasket for Flanges

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

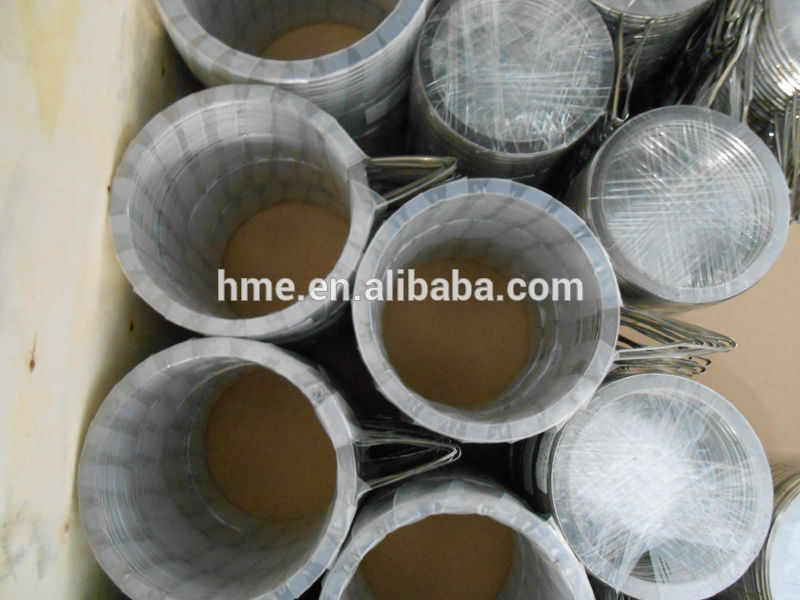

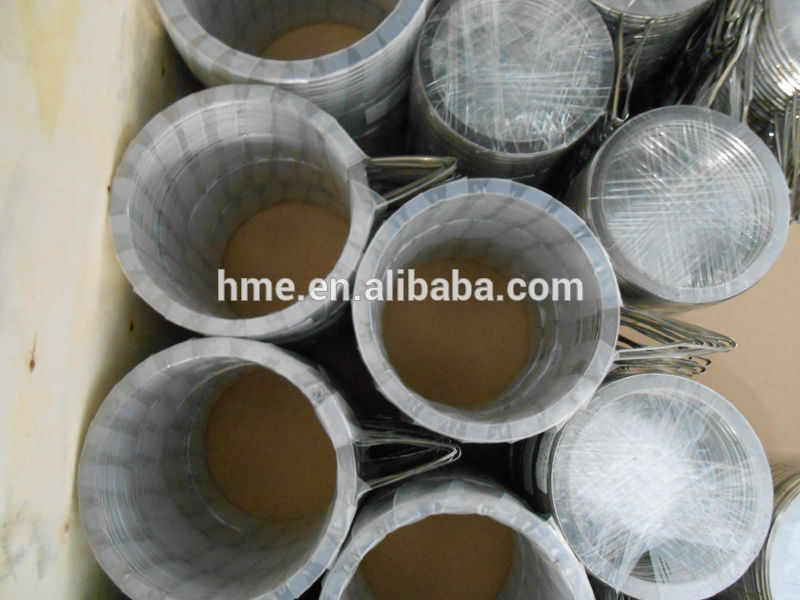

Specifications ASME B16.20 Spiral Wound Gasket for Flanges

1.Have stock, fast delivery time

2.Lowest price with best quality

ASME B16.20 Spiral Wound Gasket for Flanges Spiral Wound Gasket Type:

Product Overview: There are four types of sprial wound gasket: the basic type, the inner ring, the outer ring, and the inner&outer ring. Its widely used in electric power plant, chemical industry, chemical fertilizer plant, Polycrystalline silicon plant, Petrochemical plant, valve, flange, vessel and so on. The sprial wound gasket are good at high temperture, high pressure and erosion resistance. Products Features: 1. The material of Sprial Wound Gaskethas two parts, the metal part and the non-metal part.

2. The metal part: Carton Steel, 304, 304L, 316, 316L, Ti, Monel, Ni, Hastelloy alloy, Inconel

3. The non-metal part: Graphite, PTFE, Non-Asbestos, Asbestos 4.Make gaskets suitable for high pipeline pressure on flat or raised flange faces.

5.Temperatures from cryogenic up to 1000 °C

Spiral wound gaskets Typical Applications:

1. Pipe, valve, pump, thermal exchange, condensing tower, plain hole and man hole of flange, etc.

2. Petrochemical, chemical, mechanical manufacturer, power station, metallurgy, shipbuilding, medical and pharmaceutical unclear power station and navigation, etc.

If you interested in spiral wound gasket, pls contact us freely

If you interested in spiral wound gasket, pls contact us freely

1.Have stock, fast delivery time

2.Lowest price with best quality

ASME B16.20 Spiral Wound Gasket for Flanges Spiral Wound Gasket Type:

Style | Construction | Flange | Hoop material | Filler Material | Inner & Outer Material | Size (mm) | Thickness MM | |

1 | Basic type | Tongue and Groove | Ocr13 304 304L 316 316L 321 TI Mon400 Inconel Etc. | Graphite PTFE Asbestos Non-asbestos Ceramics

| Carbon steel 304 321 304L 316 316L T1~T3 Monel Incoloy 600-800 Hastelloy C276\C4 | 15-3000 | 2.5 to 7.2 | |

2 | With outer ring | Raised face and Flat face | ||||||

3 | With inner ring | Male and Female | ||||||

4 | With inner and outer ring | Raised face and Flat face | ||||||

5 | For heat exchanger | Heat exchanger | ||||||

2. The metal part: Carton Steel, 304, 304L, 316, 316L, Ti, Monel, Ni, Hastelloy alloy, Inconel

3. The non-metal part: Graphite, PTFE, Non-Asbestos, Asbestos 4.Make gaskets suitable for high pipeline pressure on flat or raised flange faces.

5.Temperatures from cryogenic up to 1000 °C

Filler Material | Temperature | Pressure |

Graphite | -240°c+550 °cin oxidizing media | 300 bar in hot water, oil, etc |

|---|---|---|

-240°+800°c in non-oxidizing media | 200 bar in vapor oil, gases, etc | |

Asbestos | -150°c-+450°c | 150 bar |

PTFE | -200°c-+250°c | 150 bar |

1. Pipe, valve, pump, thermal exchange, condensing tower, plain hole and man hole of flange, etc.

2. Petrochemical, chemical, mechanical manufacturer, power station, metallurgy, shipbuilding, medical and pharmaceutical unclear power station and navigation, etc.

If you interested in spiral wound gasket, pls contact us freely

If you interested in spiral wound gasket, pls contact us freely Related Keywords

Related Keywords