China automatic gabion mesh making machine factory

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

China automatic gabion mesh making machine factory  Product Description Gabion mesh machine is professional equipment to produce hexagonal wire mesh. The “Dapu” heavy-duty hexagonal wire mesh machine, produced by this company is a special braiding machine to fabricate hexagonal mesh work, which is a new developed market-suitable product integrating the merits of domestic and oversea products. Technical Parameter

Product Description Gabion mesh machine is professional equipment to produce hexagonal wire mesh. The “Dapu” heavy-duty hexagonal wire mesh machine, produced by this company is a special braiding machine to fabricate hexagonal mesh work, which is a new developed market-suitable product integrating the merits of domestic and oversea products. Technical Parameter

Specification 1. It has advanced design and compact conformation. 2. It has attractive appearance. 3. It is easy and safe to operate. Photo of main device  Auxiliary equipment Wire tension device

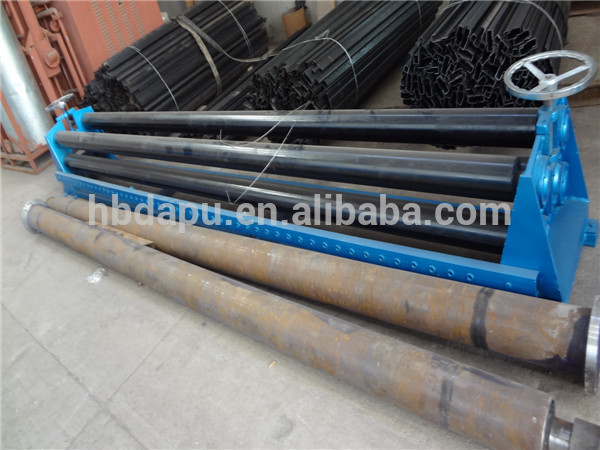

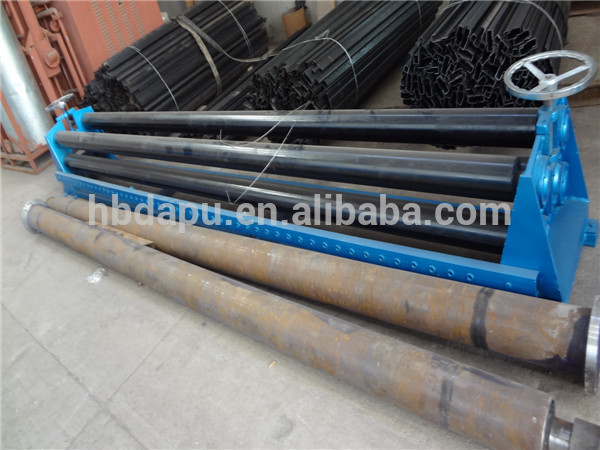

Auxiliary equipment Wire tension device  Mesh roller

Mesh roller

Quality Control We always pay more attention to the quality of our machine, Standard quality control system and team are responsible to insure the high quality in every process. We are devoted to producing a more efficiency and safer machines. Company Culture Our company is engaged in designing and exporting metal & wire mesh processing machinery, different kinds of wire mesh weaving machines and wire mesh welding machines. Our company is located in Shijiazhuang, Hebei, China. Our company has own factory - Hebei Jiake Welding Equipment Co., Ltd., which is located in the Industrial Zone of Anping, Hebei, China. Our company is a leading manufacturer of wire mesh machines in China and we always offer ADVANCED WIRE MESH TECHNOLOGY. Our Services 1. One year since the machine was installed at buyer's factory but within 18 months against B/L date. 2. 24 hour technical support by e-mail 3. We offer installation and train the workers for the customers. Contact me Welcome to our factory! Hebei Dapu Import & Export Trade Co., Ltd. Hebei Jiake Welding Equipment Co., Ltd.

Quality Control We always pay more attention to the quality of our machine, Standard quality control system and team are responsible to insure the high quality in every process. We are devoted to producing a more efficiency and safer machines. Company Culture Our company is engaged in designing and exporting metal & wire mesh processing machinery, different kinds of wire mesh weaving machines and wire mesh welding machines. Our company is located in Shijiazhuang, Hebei, China. Our company has own factory - Hebei Jiake Welding Equipment Co., Ltd., which is located in the Industrial Zone of Anping, Hebei, China. Our company is a leading manufacturer of wire mesh machines in China and we always offer ADVANCED WIRE MESH TECHNOLOGY. Our Services 1. One year since the machine was installed at buyer's factory but within 18 months against B/L date. 2. 24 hour technical support by e-mail 3. We offer installation and train the workers for the customers. Contact me Welcome to our factory! Hebei Dapu Import & Export Trade Co., Ltd. Hebei Jiake Welding Equipment Co., Ltd.

Product Description Gabion mesh machine is professional equipment to produce hexagonal wire mesh. The “Dapu” heavy-duty hexagonal wire mesh machine, produced by this company is a special braiding machine to fabricate hexagonal mesh work, which is a new developed market-suitable product integrating the merits of domestic and oversea products. Technical Parameter

Product Description Gabion mesh machine is professional equipment to produce hexagonal wire mesh. The “Dapu” heavy-duty hexagonal wire mesh machine, produced by this company is a special braiding machine to fabricate hexagonal mesh work, which is a new developed market-suitable product integrating the merits of domestic and oversea products. Technical Parameter | Model

| Mesh Size(mm) | Max. Width(mm) | Wire diameter(mm) | Twisting Number | Main Drive Shaft Speed(r/min) | Motor Capacity(KW) | Theoretical Speed(m/h) |

LNWL23-60-2 | 60*80 | 2300 | 1.6-3.0 | 3 | 25 | 11 | 165 |

LNWL23-80-2 | 80*100 | 1.6-3.0 | 195 | ||||

LNWL23-100-2 | 100*120 | 1.6-3.5 | 225 | ||||

LNWL23-1200-2 | 120*150 | 1.6-3.2 | 20 | 255 | |||

LNWL33-60-2 | 60*80 | 3300 | 1.6-2.8 | 25 | 15 | 165 | |

LNWL33-80-2 | 80*100 | 1.6-3.0 | 195 | ||||

LNWL33-100-2 | 100*120 | 1.6-3.2 | 225 | ||||

LNWL33-120-2 | 120*150 | 1.6-3.5 | 20 | 255 | |||

LNWL43-60-2 | 60*80 | 4300 | 1.6-2.8 | 25 | 22 | 165 | |

LNWL43-80-2 | 80*100 | 1.6-3.0 | 195 | ||||

LNWL43-100-2 | 100*120 | 1.6-3.0 | 225 | ||||

LNWL43-120-2 | 120*150 | 1.6-3.2 | 20 | 255 | |||

LNWL43-60-3 | 60*80 | 4300 | 1.6-2.8 | 5 | 25 | 2 | 165 |

LNWL43-80-3 | 80*100 | 1.6-3.0 | 195 | ||||

LNWL43-100-3 | 100*!20 | 1.6-3.0 | 225 | ||||

LNWL43-120-3 | 120*150 | 1.6-3.2 | 20 | 255 |

Auxiliary equipment Wire tension device

Auxiliary equipment Wire tension device  Mesh roller

Mesh roller

Quality Control We always pay more attention to the quality of our machine, Standard quality control system and team are responsible to insure the high quality in every process. We are devoted to producing a more efficiency and safer machines. Company Culture Our company is engaged in designing and exporting metal & wire mesh processing machinery, different kinds of wire mesh weaving machines and wire mesh welding machines. Our company is located in Shijiazhuang, Hebei, China. Our company has own factory - Hebei Jiake Welding Equipment Co., Ltd., which is located in the Industrial Zone of Anping, Hebei, China. Our company is a leading manufacturer of wire mesh machines in China and we always offer ADVANCED WIRE MESH TECHNOLOGY. Our Services 1. One year since the machine was installed at buyer's factory but within 18 months against B/L date. 2. 24 hour technical support by e-mail 3. We offer installation and train the workers for the customers. Contact me Welcome to our factory! Hebei Dapu Import & Export Trade Co., Ltd. Hebei Jiake Welding Equipment Co., Ltd.

Quality Control We always pay more attention to the quality of our machine, Standard quality control system and team are responsible to insure the high quality in every process. We are devoted to producing a more efficiency and safer machines. Company Culture Our company is engaged in designing and exporting metal & wire mesh processing machinery, different kinds of wire mesh weaving machines and wire mesh welding machines. Our company is located in Shijiazhuang, Hebei, China. Our company has own factory - Hebei Jiake Welding Equipment Co., Ltd., which is located in the Industrial Zone of Anping, Hebei, China. Our company is a leading manufacturer of wire mesh machines in China and we always offer ADVANCED WIRE MESH TECHNOLOGY. Our Services 1. One year since the machine was installed at buyer's factory but within 18 months against B/L date. 2. 24 hour technical support by e-mail 3. We offer installation and train the workers for the customers. Contact me Welcome to our factory! Hebei Dapu Import & Export Trade Co., Ltd. Hebei Jiake Welding Equipment Co., Ltd. Related Keywords

Related Keywords

You May Also Like

You May Also Like