Filter tube mesh welding machine

- Delivery Time:

- 90 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

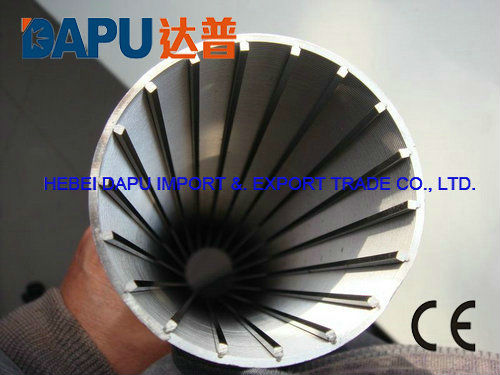

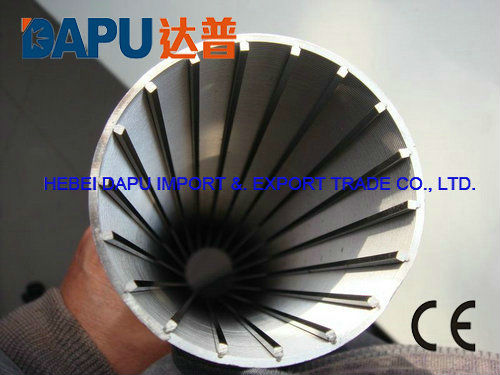

Specifications Filter tube mesh welding machine

Wire diameter:2-5mm

Tube diameter:30-1200mm

Tube length:6m

iso9001:2000;CE

Filter tube mesh welding machine Filter tube mesh welding machine Function Characteristics:

Filter tube mesh welding machine Function Characteristics:

1. Our wedged wire screen mesh welding machine have the strongpoint of low noise, low energy consumption and stable function.

2. The electrical control system is researched and developed by ourselves; main axis and feeding axis are both adopt Panasonic Brand AC power servo motor and drivers.

3. Slot size adopt NC servo motor to drive ball-screws. Ball-screws drive the drawing support rods plate sliding on linear guideway according to the instructions, slot size could be adjusted randomly.

4. Machine parameters display visually and conveniently, simple and easy to do. Ball-screws and linear guideway both adopt import famous brand products.

5. The machine are combined by CD61100 lathe, welding control cabinet, transformer and wire press unit, it has strongpoint of welding hole distance. Usage: Welding wire wrapped screen pipe, mineral filtrating mesh, coal washing mesh, water filtrating mesh, water well screen etc. Main parameters:

Main parameters:

Automatic mode-input correct variable value then the machine can work automatic cycle.

Adjustable mode-every parts of movement of machine could be adjustable, like a manual mode

Accessorial Parts:

V-shaped wire machine; wire rolling machine; straightening&cutting machine; electric control cabinet; flatter mesh machine; cutting mesh machine

Note: Two motors, one for drawing mesh 2kw, one for rolling the mould 3kw After-sale service:

1.We can offer installation and train the workers for the customers.

2.Guarantee time:one year since the machine was installed at buyer's factory but within 18 months against B/L date.

3. We can help design the layout of the machine placed in the factory.

Wire diameter:2-5mm

Tube diameter:30-1200mm

Tube length:6m

iso9001:2000;CE

Filter tube mesh welding machine

1. Our wedged wire screen mesh welding machine have the strongpoint of low noise, low energy consumption and stable function.

2. The electrical control system is researched and developed by ourselves; main axis and feeding axis are both adopt Panasonic Brand AC power servo motor and drivers.

3. Slot size adopt NC servo motor to drive ball-screws. Ball-screws drive the drawing support rods plate sliding on linear guideway according to the instructions, slot size could be adjusted randomly.

4. Machine parameters display visually and conveniently, simple and easy to do. Ball-screws and linear guideway both adopt import famous brand products.

5. The machine are combined by CD61100 lathe, welding control cabinet, transformer and wire press unit, it has strongpoint of welding hole distance. Usage: Welding wire wrapped screen pipe, mineral filtrating mesh, coal washing mesh, water filtrating mesh, water well screen etc.

Main parameters:

Main parameters:Automatic mode-input correct variable value then the machine can work automatic cycle.

Adjustable mode-every parts of movement of machine could be adjustable, like a manual mode

Model | 50—200mm | 100—600mm | 600—1200mm |

Power | 3Phase 380V 50Hz | 3Phase 380V 50Hz | 3Phase 380V 50Hz |

Rated capacity | 100KVA | 100KVA | 100KVA |

Slot distance | ≥0.1mm | ≥0.2mm | ≥0.25mm |

Canister length | Max 6000mm | Max 6000mm | Max 4000mm |

Weld material | Stainless steel wire & Low carbon steel wire | ||

V-wire size | 1.8—5.0mm | 1.8—5.0mm | 1.8—5.0mm |

Support rod size | 1.8—5.0mm | 1.8—5.0mm | 1.8—5.0mm |

Overall dimension | 13000*1500*3300mm | 13000*1600*3400mm | 11000*2100*3800mm |

Weight | 10000KG | 11000KG | 13000KG |

V-shaped wire machine; wire rolling machine; straightening&cutting machine; electric control cabinet; flatter mesh machine; cutting mesh machine

Note: Two motors, one for drawing mesh 2kw, one for rolling the mould 3kw After-sale service:

1.We can offer installation and train the workers for the customers.

2.Guarantee time:one year since the machine was installed at buyer's factory but within 18 months against B/L date.

3. We can help design the layout of the machine placed in the factory.

Related Keywords

Related Keywords