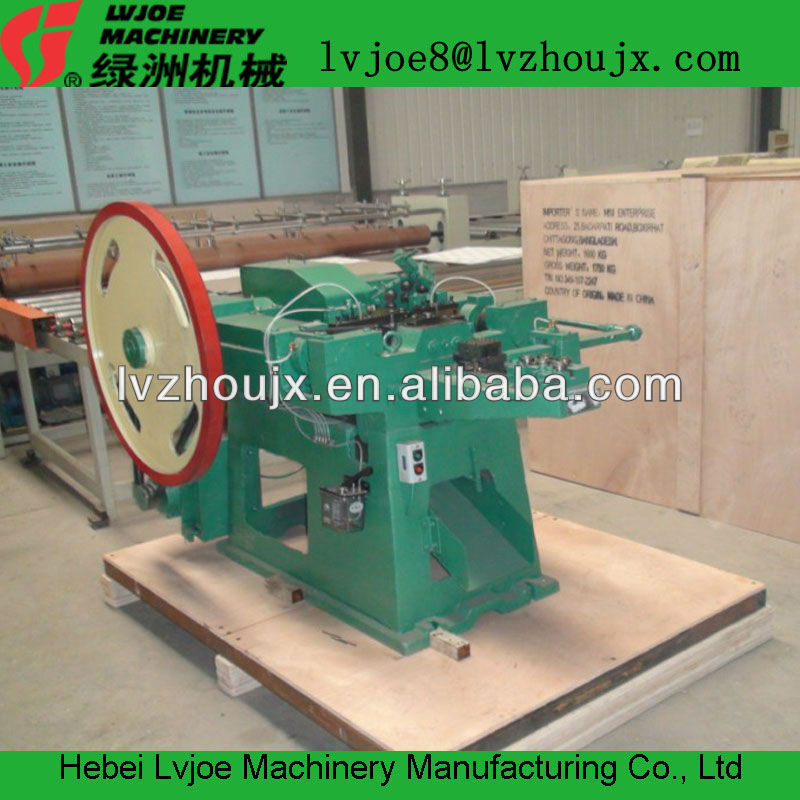

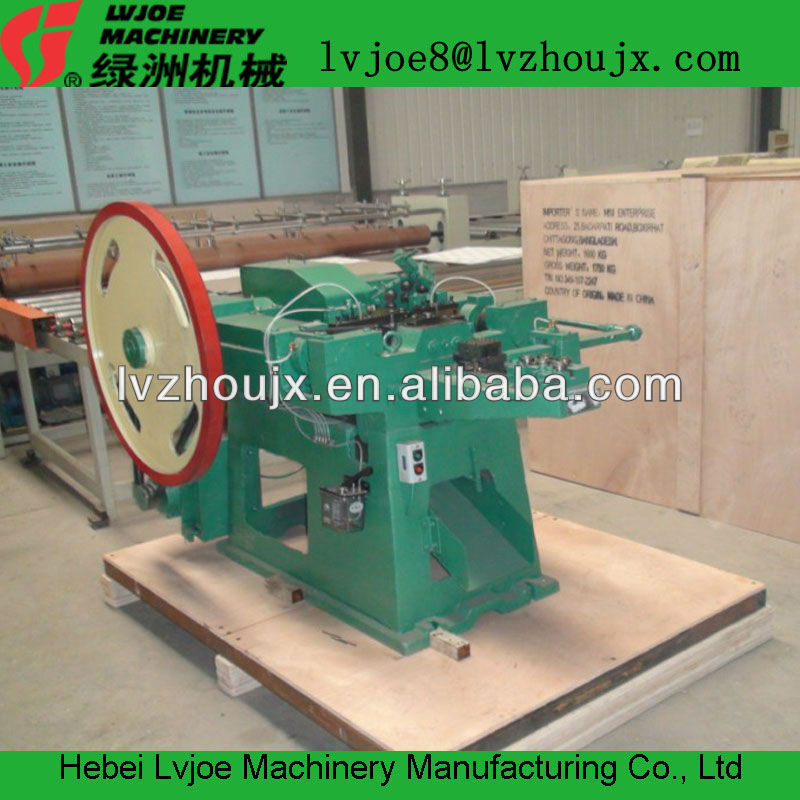

automatic Z-94C nail making machine China manufacturer

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Specifications wire nail making machine can produce different kinds of nails

wire nail making machine Usage:This machine adopts plunger type structure so as to ensure the features such as high speed, low noise and less impact.Especially,it can make the high quality of oil rivet nail and other shaped nails used for high speed welding nailer and nail gun. Features :

(1) The machine has attractive appearance, rational structure and high efficiency. It's also v durable in use, easy to maintenance with adequate durability.

(2) All the main components are made of quality steel, such as shaft, cams and gear.

(3) Use control handle at the inlet place in order to control incoming line at any time during operating.

(4) A friction gear is installed between crankshaft and flywheel. It plays a protective role of safety when the machine breaks down or overloaded.

(5) The machine makes use of full automatic production procedure. Once start, it could make nails continuously. Specifications

Process flows:

Steel wire - wire drawing - nail making nail washing - finished nail Finished product

Nail making machine

Nail making machine

welcome to visit our factory Ms quinna skype: lanquinna1989 cellphone number: 008613315978260

welcome to visit our factory Ms quinna skype: lanquinna1989 cellphone number: 008613315978260

wire nail making machine Usage:This machine adopts plunger type structure so as to ensure the features such as high speed, low noise and less impact.Especially,it can make the high quality of oil rivet nail and other shaped nails used for high speed welding nailer and nail gun. Features :

(1) The machine has attractive appearance, rational structure and high efficiency. It's also v durable in use, easy to maintenance with adequate durability.

(2) All the main components are made of quality steel, such as shaft, cams and gear.

(3) Use control handle at the inlet place in order to control incoming line at any time during operating.

(4) A friction gear is installed between crankshaft and flywheel. It plays a protective role of safety when the machine breaks down or overloaded.

(5) The machine makes use of full automatic production procedure. Once start, it could make nails continuously. Specifications

Type | 1C | 2C | 3C | 4C | 5C | 6C |

Max nail length (mm) | 10-20 | 20-50 | 30-75 | 50-100 | 100-150 | 150-210 |

Max nail dia (mm) | 0.9-1.2 (standard) 0.9-1.6 (non standard) | 1.6-2.5 (standard) 1.2-2.8 (non standard) | 1.8-3.2 (standard) 1.8-3.4 (non standard) | 2.8-4.0 (standard) 2.8-4.5 (non standard) | 3.7-5.0 (standard) 3.7-5.5 (non standard) | 5.0-7.0 (standard) 5.0-7.0 (standard) |

Nail making speed (pcs/min) | 450 | 300 | 280 | 250 | 250 | 180 |

Capacity | 78kg/8 hrs | 500 kg/8hrs | 880 kg/8hrs | 2230 kg/8hrs | 4900 kg/8hrs | 5000 kg/8hrs |

Motor power (kw) | 1.5 | 2.2 | 3 | 4 | 5.5 | 11 |

Power consumption | 1.5 kw/h | 2.2 kw/h | 3 kw/h | 4 kw/h | 5.5 kw/h | 11 kw/h |

Weight (kg) | 900 | 1350 | 1600 | 1900 | 2500 | 5500 |

Overall dimension (mm) | 1350*950*1000 | 1650*1150*1100 | 1990*1200*1250 | 2280*1420*1330 | 2300*1450*1500 | 3510*1940*2015 |

Steel wire - wire drawing - nail making nail washing - finished nail Finished product

Nail making machine

Nail making machine

welcome to visit our factory Ms quinna skype: lanquinna1989 cellphone number: 008613315978260

welcome to visit our factory Ms quinna skype: lanquinna1989 cellphone number: 008613315978260 Related Keywords

Related Keywords