5'' inch (127mm) G105 Oil Drilling Pipe

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

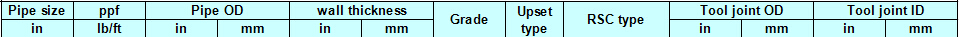

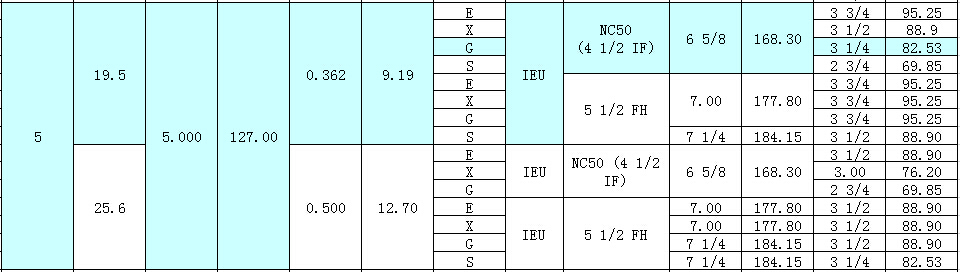

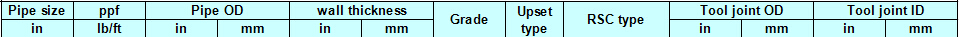

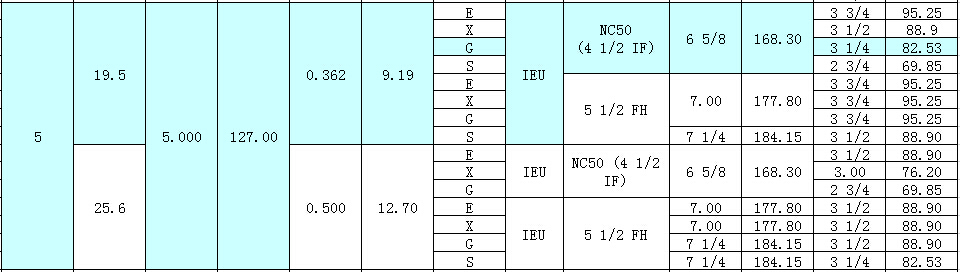

5" G105 Oil Drill pipe # ALIBABA Hot Selling From Longway

More information:

More information:  1. Strictly according to API 5DP standard

1. Strictly according to API 5DP standard

2. Yield strength: Min 724Mpa

3. Tensile strength: Min 793Mpa

4. Pipe body material: High quality alloy seamless pipe of G105

5. Tool joint: 4137H

6. Thread treatment: Phosphorization or copper plating

7. Suitable for gas well, oil well

8. Safe drilling depth: Within 3,000 meters

Certification:

1. ISO 9001: 2008

2. API 5DP-0011 3. GOST No.: 1739641

Packing detail: 1. The drill pipes will be packed into bundles as 3x3, 3x4, 4x4 etc. and loading into containers after black painting and thread protectors installation. 2. For 20’ container, the max loading weight is 21 metric tons 3. For 40’ container, the max loading weight is 27 metric tons 4. Usual loading port is Xingang port in Tianjin, main port in north of China Drill pipe quality control: a) Before order to be confirmed, the raw material of pipe body and tool joint should be booked from famous big steel enterprises in China b) Raw material’s size, quantity, length, mechanical property are checked by our QC staff and factory own laboratory c) Every drill pipe has nondestructive inspection , cleaned and thread oil before packing. d) Before delivery clients could send one QC or point the third party to check the quality such SGS, BV or others Drill pipe usage notes: 1. New drill pipe should be pasted thread oil before connection 2. Make up and break at least 3 times before drilling 3. Hard bending and plastic coating can be processed according to clients’ special requirements Our workshop:

Our workshop:

Most advanced production line all over the world

1.USA MTI friction welding machine

2.Whole pipe heat treatment equipment

3.Forging process tool joint line

4.100% nondestructive inspection by ultrasonic flaw and magnetic Service for oilfield worldwide: Today,our products not only sold to domestic oilfield in North China,Daqing,Jilin,Changchun and so on, but also exported to France,Canada,India,Kazakhstan,Turky,Chile,Argentina,Egypt,Sudan,Iran,UAE,South Korea, Ukraine,Russia,Uzbekistan,Singapore,Australia and so on.

Service for oilfield worldwide: Today,our products not only sold to domestic oilfield in North China,Daqing,Jilin,Changchun and so on, but also exported to France,Canada,India,Kazakhstan,Turky,Chile,Argentina,Egypt,Sudan,Iran,UAE,South Korea, Ukraine,Russia,Uzbekistan,Singapore,Australia and so on.  *Longway is professional production of drilling tools, if you want to know more about our products, pls feel free to contact us. *Betty at your service in 24 hours Skype:lwdrillsales6 Mobile: +86-18633912255 QQ:2483698627 ------------------------------------------------------------------------ Longway's best quality drill pipe of API standard

*Longway is professional production of drilling tools, if you want to know more about our products, pls feel free to contact us. *Betty at your service in 24 hours Skype:lwdrillsales6 Mobile: +86-18633912255 QQ:2483698627 ------------------------------------------------------------------------ Longway's best quality drill pipe of API standard

More information:

More information:  1. Strictly according to API 5DP standard

1. Strictly according to API 5DP standard 2. Yield strength: Min 724Mpa

3. Tensile strength: Min 793Mpa

4. Pipe body material: High quality alloy seamless pipe of G105

5. Tool joint: 4137H

6. Thread treatment: Phosphorization or copper plating

7. Suitable for gas well, oil well

8. Safe drilling depth: Within 3,000 meters

Certification:

1. ISO 9001: 2008

2. API 5DP-0011 3. GOST No.: 1739641

Packing detail: 1. The drill pipes will be packed into bundles as 3x3, 3x4, 4x4 etc. and loading into containers after black painting and thread protectors installation. 2. For 20’ container, the max loading weight is 21 metric tons 3. For 40’ container, the max loading weight is 27 metric tons 4. Usual loading port is Xingang port in Tianjin, main port in north of China Drill pipe quality control: a) Before order to be confirmed, the raw material of pipe body and tool joint should be booked from famous big steel enterprises in China b) Raw material’s size, quantity, length, mechanical property are checked by our QC staff and factory own laboratory c) Every drill pipe has nondestructive inspection , cleaned and thread oil before packing. d) Before delivery clients could send one QC or point the third party to check the quality such SGS, BV or others Drill pipe usage notes: 1. New drill pipe should be pasted thread oil before connection 2. Make up and break at least 3 times before drilling 3. Hard bending and plastic coating can be processed according to clients’ special requirements

Our workshop:

Our workshop:Most advanced production line all over the world

1.USA MTI friction welding machine

2.Whole pipe heat treatment equipment

3.Forging process tool joint line

4.100% nondestructive inspection by ultrasonic flaw and magnetic

Service for oilfield worldwide: Today,our products not only sold to domestic oilfield in North China,Daqing,Jilin,Changchun and so on, but also exported to France,Canada,India,Kazakhstan,Turky,Chile,Argentina,Egypt,Sudan,Iran,UAE,South Korea, Ukraine,Russia,Uzbekistan,Singapore,Australia and so on.

Service for oilfield worldwide: Today,our products not only sold to domestic oilfield in North China,Daqing,Jilin,Changchun and so on, but also exported to France,Canada,India,Kazakhstan,Turky,Chile,Argentina,Egypt,Sudan,Iran,UAE,South Korea, Ukraine,Russia,Uzbekistan,Singapore,Australia and so on.  *Longway is professional production of drilling tools, if you want to know more about our products, pls feel free to contact us. *Betty at your service in 24 hours Skype:lwdrillsales6 Mobile: +86-18633912255 QQ:2483698627 ------------------------------------------------------------------------ Longway's best quality drill pipe of API standard

*Longway is professional production of drilling tools, if you want to know more about our products, pls feel free to contact us. *Betty at your service in 24 hours Skype:lwdrillsales6 Mobile: +86-18633912255 QQ:2483698627 ------------------------------------------------------------------------ Longway's best quality drill pipe of API standard Related Keywords

Related Keywords