2014 Year streamlined biomass briquette machine

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

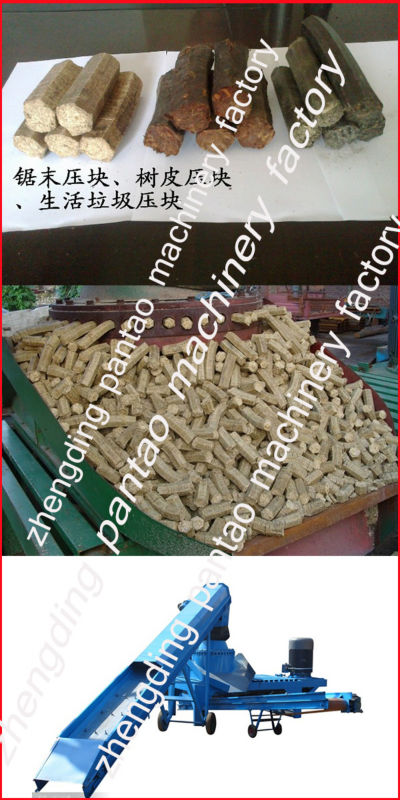

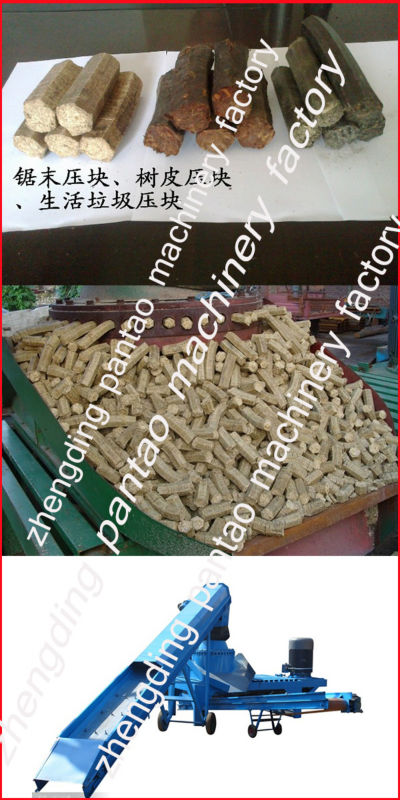

Specifications Electric wood sawdust briquette machine

1.energy saving

2.easy to operate

3.less smoke

4.no addictives

2014 Year biomass biomass briquette machine Zhengding pantao machinery factory after more than eight years on the market researchaccording to the existing equipment and material of different features and in-depth, research and development of new type ring die equipment, biomass briquetting of wear-resistingsleeve design, solve the equipment before compression ratio on t he market changes the complex difficult problem, so as to make the finished product density in domestic at presen t belongs to the first, the device to solve the problem of the boring machine equipment delay production, also grea tly reduce the failure rate! Pantao machinery factory to break the original square hole on the market company module disassembling complex patterns, 120-120 screw need only 22 all screws can be fixed, tear open outfit on ly need to change wear-resisting set of wear-resisting layer, and the press pulley without screw, disassembling time saving to one over ten of the past, to save time and effort! Wear-resisting set can design circle six ling and other specifications according to customer's need! The reasonable design of assembling the square avoids the pressure before the wheel wear and material for the motherboard, truly achieve the goal of easy to drag down the lowest co st parts. Pantao machinery factoryovercome the majority of block making machine on the market before will not be able tocompress the rice husk of wood shavings and other shortcomings, completely got the control of the above several difficult to machining materials of compression technology, production 1-2 tons, the production is very stable. Main USES: can be widely used in all kinds of grass straw, rice straw, straw briquette, wheat straw, corn stalks, peanut straw briquette, haulm, bark, and cotton seed hull roughage and cotton straw, shrub and forest products scraps from the biomass density curing processing briquetting equipment. It is the production of dense curing feed, biomass density curing fuel ideal straw briquetting equipment.

1.energy saving

2.easy to operate

3.less smoke

4.no addictives

2014 Year biomass biomass briquette machine Zhengding pantao machinery factory after more than eight years on the market researchaccording to the existing equipment and material of different features and in-depth, research and development of new type ring die equipment, biomass briquetting of wear-resistingsleeve design, solve the equipment before compression ratio on t he market changes the complex difficult problem, so as to make the finished product density in domestic at presen t belongs to the first, the device to solve the problem of the boring machine equipment delay production, also grea tly reduce the failure rate! Pantao machinery factory to break the original square hole on the market company module disassembling complex patterns, 120-120 screw need only 22 all screws can be fixed, tear open outfit on ly need to change wear-resisting set of wear-resisting layer, and the press pulley without screw, disassembling time saving to one over ten of the past, to save time and effort! Wear-resisting set can design circle six ling and other specifications according to customer's need! The reasonable design of assembling the square avoids the pressure before the wheel wear and material for the motherboard, truly achieve the goal of easy to drag down the lowest co st parts. Pantao machinery factoryovercome the majority of block making machine on the market before will not be able tocompress the rice husk of wood shavings and other shortcomings, completely got the control of the above several difficult to machining materials of compression technology, production 1-2 tons, the production is very stable. Main USES: can be widely used in all kinds of grass straw, rice straw, straw briquette, wheat straw, corn stalks, peanut straw briquette, haulm, bark, and cotton seed hull roughage and cotton straw, shrub and forest products scraps from the biomass density curing processing briquetting equipment. It is the production of dense curing feed, biomass density curing fuel ideal straw briquetting equipment.

Related Keywords

Related Keywords