3000 PCS/H 4 Surface Egg Tray Machine

- Delivery Time:

- 25 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Thank you for having a visit on Zhengding Pantao Machinery Factory!  About us: It is a long history for our company producing Egg Tray Machine since 1990s. We have experience and professional technology in the field where to produce the egg tray forming machine. Besides, our engineers will service machinery overseas until the clients get how to operate it. Not only does our factory produce type of 1000 pcs/h, 2000 pcs /h, 2500 pcs/h, 3000 pcs/h, 3500pcs/h, 4000pcs/h, but also makes any type machines to clients orders.

About us: It is a long history for our company producing Egg Tray Machine since 1990s. We have experience and professional technology in the field where to produce the egg tray forming machine. Besides, our engineers will service machinery overseas until the clients get how to operate it. Not only does our factory produce type of 1000 pcs/h, 2000 pcs /h, 2500 pcs/h, 3000 pcs/h, 3500pcs/h, 4000pcs/h, but also makes any type machines to clients orders.

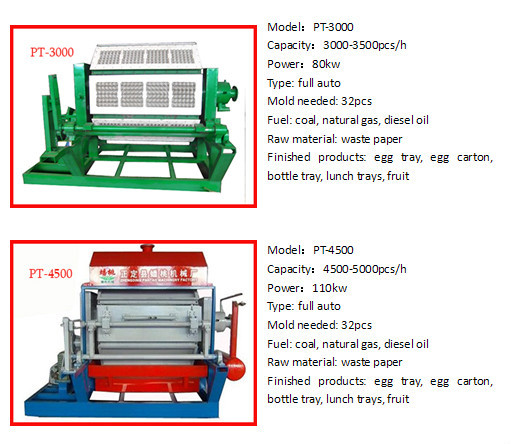

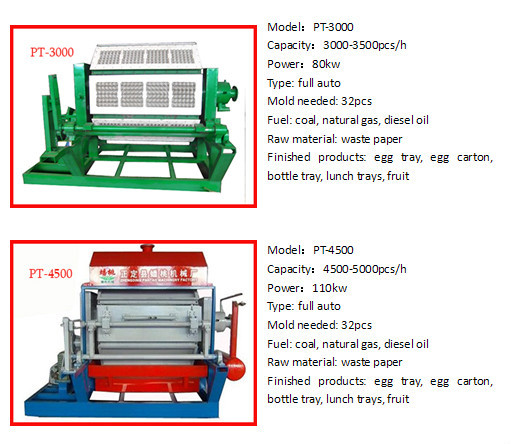

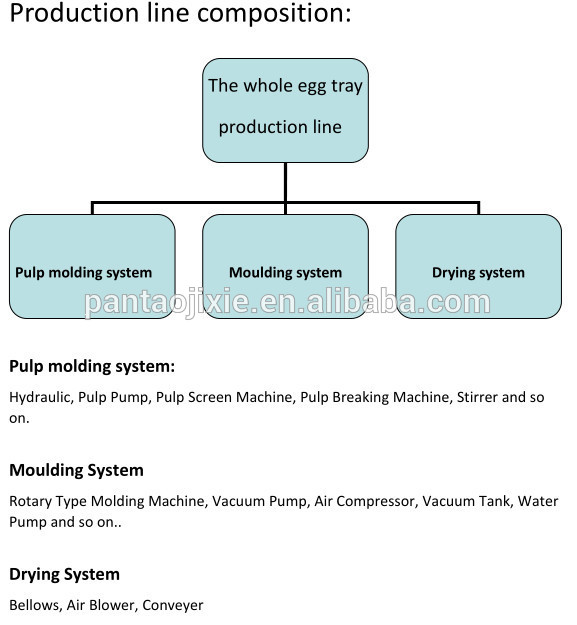

Product Description: 3000 PCS/H egg tray machine Oprating principle: The waste paper recycling egg tray forming machine makes trays by rotary. And 4 pieces once,3500 pieces per hour. And it can make egg trays, egg boxes, apple trays, meat portion trays, vegetable portion trays, fruit portion trays, wine packs, can trays, seed pots, seed cubes, shoe stretcher etc.

Product Description: 3000 PCS/H egg tray machine Oprating principle: The waste paper recycling egg tray forming machine makes trays by rotary. And 4 pieces once,3500 pieces per hour. And it can make egg trays, egg boxes, apple trays, meat portion trays, vegetable portion trays, fruit portion trays, wine packs, can trays, seed pots, seed cubes, shoe stretcher etc.  Product Process: Put raw materials into the pulper, add water and stir the pulp. The forming machine makes egg trays. Transmit the finished egg trays from forming machine to the dry hole by a conveyor. And dry them. Put in order and package egg trays.

Product Process: Put raw materials into the pulper, add water and stir the pulp. The forming machine makes egg trays. Transmit the finished egg trays from forming machine to the dry hole by a conveyor. And dry them. Put in order and package egg trays. Introductions: 1. Raw materials: (for step 1) A. Pulp Board Different pulp made by bulrush, straw, bagasse, bamboo, wood etc. B. Waste Paper Such as paper board, carton, newspaper, magazine, waste pulp. C. Plant Fiber Palm fiber, straw fiber, sugarcane fiber etc.

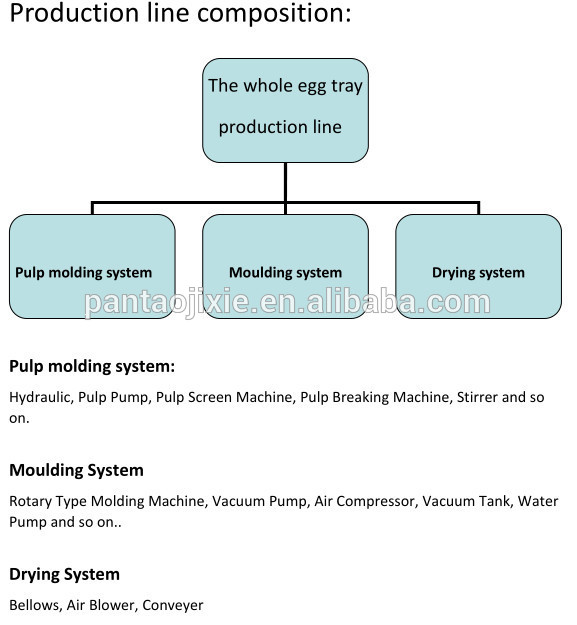

Introductions: 1. Raw materials: (for step 1) A. Pulp Board Different pulp made by bulrush, straw, bagasse, bamboo, wood etc. B. Waste Paper Such as paper board, carton, newspaper, magazine, waste pulp. C. Plant Fiber Palm fiber, straw fiber, sugarcane fiber etc.  2. Configures: For step 1: Hydrapulper, Pulp Pump, For step 2: Air Compressor, Agitator, Self Priming Pump, Pulping Machine. Egg tray Forming Machine, Vacuum Pump, High Pressure Washer, Pressure Tank, Mould, Transfer Mould, Baler,Low Vacuum Filling Machine. For step 3: Induced Draft Fan, Conveyor, Fan, Mesh Bag Actuator, Dry Iron Roller, Mesh Belt Slide, Mesh Belt Bag.

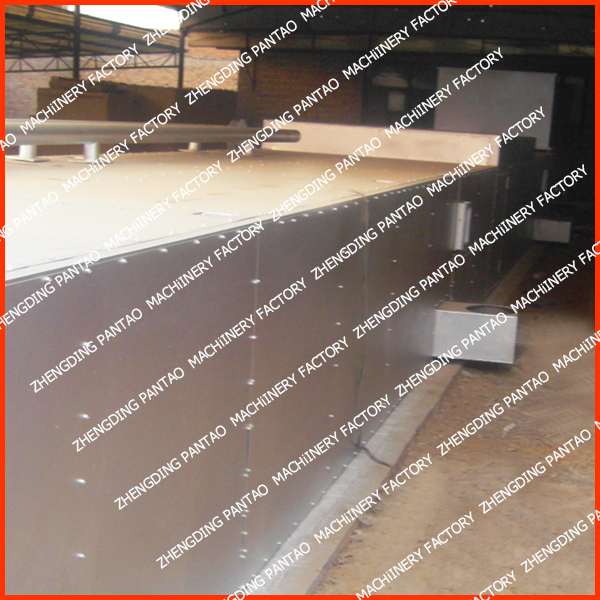

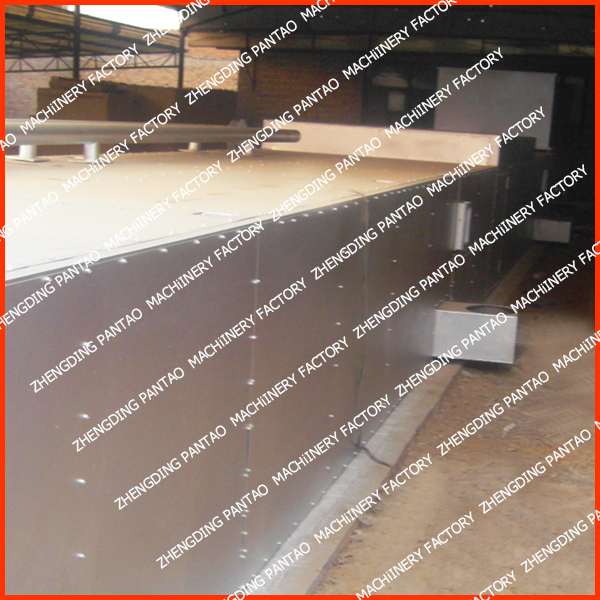

2. Configures: For step 1: Hydrapulper, Pulp Pump, For step 2: Air Compressor, Agitator, Self Priming Pump, Pulping Machine. Egg tray Forming Machine, Vacuum Pump, High Pressure Washer, Pressure Tank, Mould, Transfer Mould, Baler,Low Vacuum Filling Machine. For step 3: Induced Draft Fan, Conveyor, Fan, Mesh Bag Actuator, Dry Iron Roller, Mesh Belt Slide, Mesh Belt Bag.  3. Drying methods: (you can choose the best one which fits your order) A. Single Brick Drying Line. B. Single Metal Drying Line. C. Multi Metal Drying Line.

3. Drying methods: (you can choose the best one which fits your order) A. Single Brick Drying Line. B. Single Metal Drying Line. C. Multi Metal Drying Line.

4. The machine needs 5-7 labors to operate it. If you want to have a field visit, please contact us. Enjoy your time!

4. The machine needs 5-7 labors to operate it. If you want to have a field visit, please contact us. Enjoy your time!

About us: It is a long history for our company producing Egg Tray Machine since 1990s. We have experience and professional technology in the field where to produce the egg tray forming machine. Besides, our engineers will service machinery overseas until the clients get how to operate it. Not only does our factory produce type of 1000 pcs/h, 2000 pcs /h, 2500 pcs/h, 3000 pcs/h, 3500pcs/h, 4000pcs/h, but also makes any type machines to clients orders.

About us: It is a long history for our company producing Egg Tray Machine since 1990s. We have experience and professional technology in the field where to produce the egg tray forming machine. Besides, our engineers will service machinery overseas until the clients get how to operate it. Not only does our factory produce type of 1000 pcs/h, 2000 pcs /h, 2500 pcs/h, 3000 pcs/h, 3500pcs/h, 4000pcs/h, but also makes any type machines to clients orders.

Product Description: 3000 PCS/H egg tray machine Oprating principle: The waste paper recycling egg tray forming machine makes trays by rotary. And 4 pieces once,3500 pieces per hour. And it can make egg trays, egg boxes, apple trays, meat portion trays, vegetable portion trays, fruit portion trays, wine packs, can trays, seed pots, seed cubes, shoe stretcher etc.

Product Description: 3000 PCS/H egg tray machine Oprating principle: The waste paper recycling egg tray forming machine makes trays by rotary. And 4 pieces once,3500 pieces per hour. And it can make egg trays, egg boxes, apple trays, meat portion trays, vegetable portion trays, fruit portion trays, wine packs, can trays, seed pots, seed cubes, shoe stretcher etc.  Product Process: Put raw materials into the pulper, add water and stir the pulp. The forming machine makes egg trays. Transmit the finished egg trays from forming machine to the dry hole by a conveyor. And dry them. Put in order and package egg trays.

Product Process: Put raw materials into the pulper, add water and stir the pulp. The forming machine makes egg trays. Transmit the finished egg trays from forming machine to the dry hole by a conveyor. And dry them. Put in order and package egg trays. Introductions: 1. Raw materials: (for step 1) A. Pulp Board Different pulp made by bulrush, straw, bagasse, bamboo, wood etc. B. Waste Paper Such as paper board, carton, newspaper, magazine, waste pulp. C. Plant Fiber Palm fiber, straw fiber, sugarcane fiber etc.

Introductions: 1. Raw materials: (for step 1) A. Pulp Board Different pulp made by bulrush, straw, bagasse, bamboo, wood etc. B. Waste Paper Such as paper board, carton, newspaper, magazine, waste pulp. C. Plant Fiber Palm fiber, straw fiber, sugarcane fiber etc.  2. Configures: For step 1: Hydrapulper, Pulp Pump, For step 2: Air Compressor, Agitator, Self Priming Pump, Pulping Machine. Egg tray Forming Machine, Vacuum Pump, High Pressure Washer, Pressure Tank, Mould, Transfer Mould, Baler,Low Vacuum Filling Machine. For step 3: Induced Draft Fan, Conveyor, Fan, Mesh Bag Actuator, Dry Iron Roller, Mesh Belt Slide, Mesh Belt Bag.

2. Configures: For step 1: Hydrapulper, Pulp Pump, For step 2: Air Compressor, Agitator, Self Priming Pump, Pulping Machine. Egg tray Forming Machine, Vacuum Pump, High Pressure Washer, Pressure Tank, Mould, Transfer Mould, Baler,Low Vacuum Filling Machine. For step 3: Induced Draft Fan, Conveyor, Fan, Mesh Bag Actuator, Dry Iron Roller, Mesh Belt Slide, Mesh Belt Bag.  3. Drying methods: (you can choose the best one which fits your order) A. Single Brick Drying Line. B. Single Metal Drying Line. C. Multi Metal Drying Line.

3. Drying methods: (you can choose the best one which fits your order) A. Single Brick Drying Line. B. Single Metal Drying Line. C. Multi Metal Drying Line.

4. The machine needs 5-7 labors to operate it. If you want to have a field visit, please contact us. Enjoy your time!

4. The machine needs 5-7 labors to operate it. If you want to have a field visit, please contact us. Enjoy your time! Related Keywords

Related Keywords