High Chrome Alloy Heavy Duty Slurry Pump

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 Sets per Month |

| Supply Ability: | 50 Sets per Month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO/CE |

| Transportation: | Ocean,Land,Air |

High Chrome Alloy Heavy Duty Slurry Pump used for Arasive and Sharp Solids Mixture

Introduction:

Brand: CNSME Model: 6/4D-AH Cerfiticate: ISO/CE Origin: China

Slurry pumps are different from normal water pumps, and they are designed for the handling of very abrasive sludge and mud.

Metal slurry pump is used to handle highly abrasive slurries in minerals and mining sectors. When the pH value of the slurry is from 5 to 14, it is a good choice to use hard metal material, which we call A05. Metal slurry pump is also the best sold pumps in SME company. Metal slurry pumps are also widely used in quarries and coal wahsing plants.

The primary applications for the SME SH metal slurry pumps are mill discharge, crusher slurry, sand and aggregate or any coarse solids or other severe, abrasive slurries especially in te copper, gold, iron ore, lead-zinc, coal or phosphate plants. The most dramatic savings will be in these applications, though savings will also be realized on find solids, like fine sand recovery or kaolin. The key advantage of the SH metal slurry pumps is the 10% to 30% lower power, long even wear life and less pump downtime, which results in lowe cost-per-ton pumped, along with better cyclone separation.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

Typical Applications:

Sand and Aggregate

Mining Industries

Ash Handling

Cyclone Feeds

Pulp and Paper

Abrasive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Specifications:

| Type | Size | Frame | Impeller: E4147A05 | Shaft Seal Type | Frame Rating(kw) | Normal Max Speed(r/min) | Max Passage Size(mm) |

| SH | 100 | D | 5 Closed Type Metal Vans, Diameter:365mm | Gland Packing, Expeller, Mechanical Seal | 60 | 1600 | 44 |

Introduction:

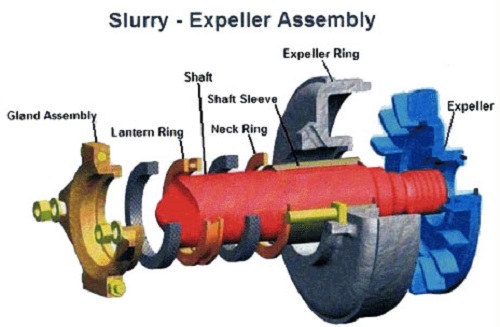

1. Shaft Seal: Expeller Seal

The effect of expeller seal is by use of pressure generated by impeller and expeller. And use packings or lip seal as shut down seal. Picture shows as below:

2. Components:

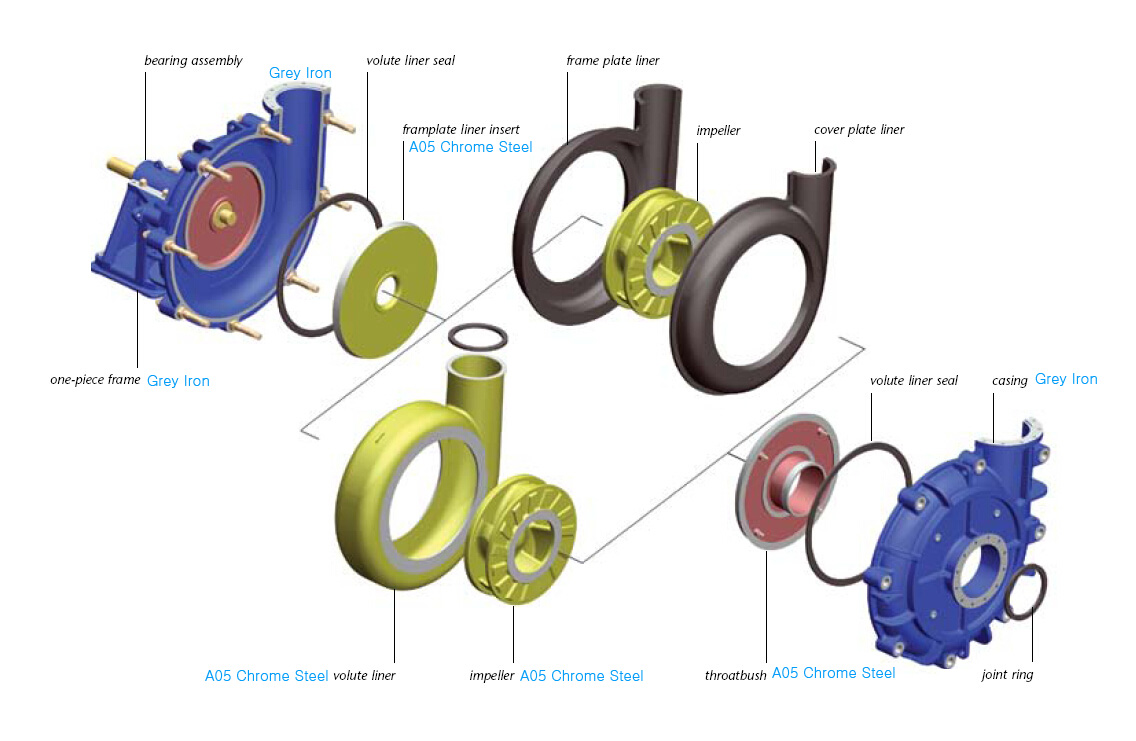

Impeller

The impeller, either elastomer, stainless steel or high-chrome material, is the main rotating component which normally has vanes to impart the centrifugal force to the liquid.

Casing

Split outer casing halves of cast contain the wear liners and provide high operation pressure capabilities. The casing shape is generally of semi-volute or concentric, efficiencies of which are less than that of the volute type.

Shaft and Bearing Assembly

A large diameter shaft with a short overhang minimizes deflection and vibration. Heavy-duty roller bearing are housed in a removable bearing cartridge.

Shaft sleeve

A hardened, heavy-duty corrosion-resistant sleeve with O-ring seals at both ends protects the shaft. A split fit allows the sleeve removed or installed quickly.

Shaft Seal

Expeller drive seal, Packing seal, Mechanical seal.

Drive Type

V-belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices.

3. Slurry pumps are made for high wearing and heavy duty applications. Our pumps and replacement parts are used worldwide industries like mining, mineral processing, power generation, aggregate processing, or any type of slurry pumping application. We specialise in handling the toughest and most abrasive applications and have taken this to a new level with the SH (War-man AH) series.

4. The primary applications for the SME SH/100D(6/4D-AH) metal slurry pumps are mill discharge, crusher slurry, sand and aggregate or any coarse solids or other severe, abrasive slurries especially in te copper, gold, iron ore, lead-zinc, coal or phosphate plants.

The most dramatic savings will be in these applications, though savings will also be realized on find solids, like fine sand recovery or kaolin. The key advantage of the SH metal slurry pumps is the 10% to 30% lower power, long even wear life and less pump downtime, which results in lowe cost-per-ton pumped, along with better cyclone separation.

Material: High Chrome Alloy A05

Material Chemical Requirements, Weight%

| Description | Material Name | C | Mn | Si | Ni | Cr | Mo | Cu | P | V | S | Description | Hardness |

| A05 | Ultrachrome | 2.92 | 0.98 | 0.54 | 0.8 | 27 | ≤0.8 | ... | 0.062 | ... | 0.051 | 27% Cr Erosion Resistant White Iron | 58-62HRC |

Construction of SH Slurry Pumps:

Performance Curve:

| AH Slurry Pump SH Series Metal Slurry Pump Specifications | ||||||||||||

|

|

||||||||||||

|

Pump Model |

S×D (inch) |

Allowable Max. Power (kw) |

Material | Clear Water Performance | Impeller | Pricing | ||||||

| Capacity Q |

Head H(m) |

Speed n(r/min) |

Max.Eff. η% |

NPSH (m) |

No. of Vanes |

Vane Dia. (mm) |

Weight (kg) |

|||||

| Impeller | m3/h | l/s | ||||||||||

| SH/25B | 1.5×1 | 15 |

Metal (A05) |

12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 5 | 152 | 91 |

| SH/40B | 2×1.5 | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 | 118 | ||

| SH/50C | 3×2 | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 | 191 | ||

| SH/75C | 4×3 | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 | 263 | ||

| SH/75D | 4×3 | 60 | 245 | 363 | ||||||||

| SH/100D | 6×4 | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 | 626 | ||

| SH/100E | 6×4 | 120 | 365 | 728 | ||||||||

| SH/150E | 8×6 | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 | 1473 | ||

| SH/150F | 8×6 | 260 | 510 | 1496 | ||||||||

| SH/150R | 8×6 | 300 | 510 | 1655 | ||||||||

| SH/200F | 10×8 | 260 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 | 3193 | ||

| SH/200ST | 10×8 | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 | 3750 | ||

| SH/250F | 12×10 | 260 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 | 3760 | ||

| SH/250ST | 12×10 | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 | 4318 | ||

| SH/300ST | 14×12 | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 | 6409 | ||

| SH/350TU | 16×14 | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 |

1067 |

10000 |

||

Related Keywords