Dredging Booster Slurry Pump

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 70 Sets per Month |

| Supply Ability: | 70 Sets per Month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

Dredging Booster Slurry Pump

Introduction:

A booster pump is pump station typically used to extend the length of the discharge line of the dredge system. Pipeline lengths can often be increased substantially with one booster. Multiple booster pumps in a system may allow for extremely long discharge line lengths. A decrease in production after added pipeline is a good indication that you may need a bosster. Booster pumps are required when dredging pumps are used in dredgers.

SBH pumps can be used for dredging booster pumps as a booster station for river or lake dreging. SBH slurry pumps are heavy duty, high head, hard metal horizontal surface high quality pumps, which are also used for mining sectors for tailings, midlings disposal. SBH pumps are designed with closed impeller of 6 vanes.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

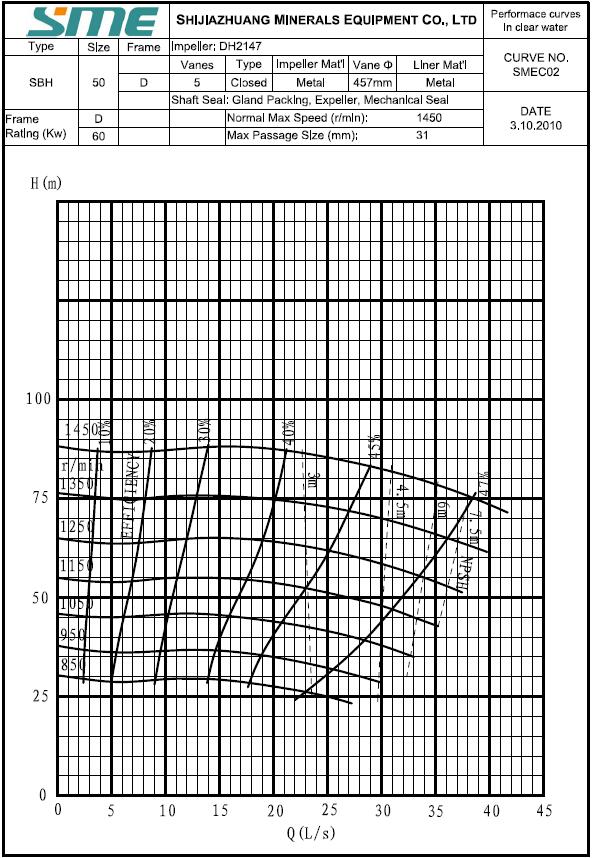

Specifications:

|

Model |

SBH-50D |

|

Outlet |

2-inch |

|

Capacity |

68.4-136.8m3/h |

|

TDH |

28-57m |

|

Rated Motor Power |

60Kw |

|

Speed |

850-1400r/min |

|

NPSH |

3-7.5m |

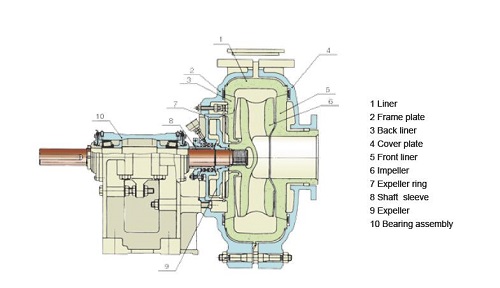

Construction of Booster Pump:

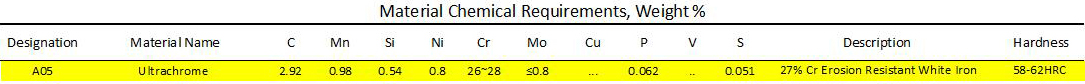

Standard Material of Wet-end Parts: Hi-Chrome Alloy A05

Typical Applications:

Tailings

Heavy Mining

Ash Handling

Cyclone Feeds

Pulp and Paper

Abrasive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Heavy Refusal Removal

Performance Curve:

Projects with Booster Pumps:

Related Keywords