Heavy duty anti wear centrifugal slurry pump

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 20 Sets per Month |

| Supply Ability: | 20 Sets per Month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO |

| Transportation: | Ocean,Land |

Heavy duty anti wear centrifugal slurry pump

Introduction:

SBH model pump pumps are cantilever and horizontal centrifugal slurry pumps. They are designed for the hardline highly abrasive, high con centration slurries. They are widely used in metallurgy industry, mining industry and so on. The pumps of this model also can be installed as multi-stage series pumps.

Features:

1. High effektifnost, wear resistance, stable performance, replaceable parts, high pressure, saving energy.

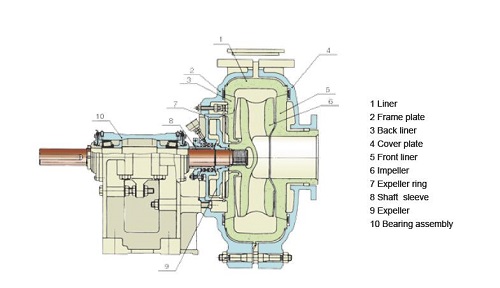

2. The main wear parts shlamvyh pumps, that is, that is, the components of the flow part: the impeller, lining cap liner pump casing liner to the front, rear bronedisk.Obychno they are made of wear-resistant metal materials razvidyh, naprimerA05, A49, and other high-chromium alloy, or elastomera.Nesuschy layer and the wear layer can be separated.

3. High-efficiency impeller large diameter, its large internal channels reduces the flow rate uvlichivaya equipment life and reducing operating costs.

4. Due to the cylindrical structure of the bearing assembly is very convenient to adjust the clearance between the impeller and the front bronediskom.Mezhdu in the bearing assembly can be completely disassembled for maintenance or lubrication detaley.Podshipniki lubricated with lubricating oil.

5. We have different types of shaft seals, including packing, mechanical seal, expeller seal and seal expeller with fillers.

6. Depending on the actual requirements of the outlet may be located at any of positions angularly 8mm interavalom 45 degrees.

7. The pumps can be serially connected to achieve high pressure.

8. Transmission Type: Direct Drive ((DC), belt drive (CR, CV, ZV, CL) pulsatile.

Related Products:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

Application of high-pressure slurry pumps SBH:

- Pumping tailings

- Power supply and transport of materials

- Concentration of ore metallurgy

- Industrial processing of salt and sugar

- Removal of slag and dust power

- Processing of mineral substances

Specifications:

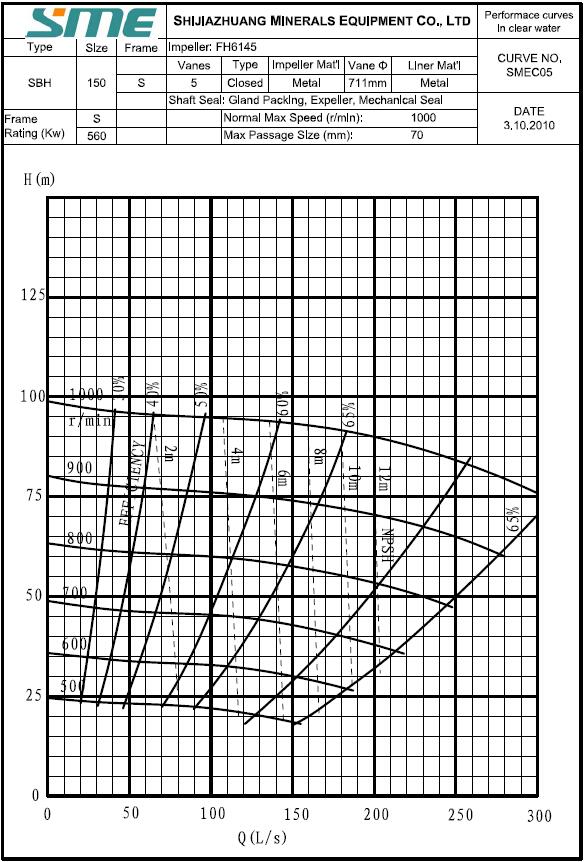

|

Model |

SBH-150S |

|

Outlet |

6-inch |

|

Capacity |

468-1008m3/h |

|

TDH |

20-94m |

|

Rated Motor Power |

560Kw |

|

Speed |

500-1000r/min |

|

NPSH |

4-12m |

Construction of Metal Slurry Pump:

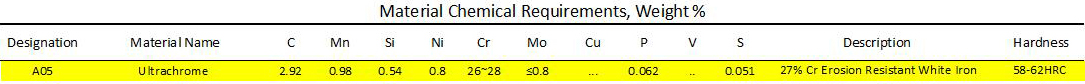

Standard Material of Wet-end Parts: Hi-Chrome Alloy A05

Performance Curve:

Projects with SME Slurry Pumps:

Related Keywords