2-Inch High Head Horizontal Slurry Pumps

- Payment Type:

- T/T

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Beijing, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO, CE |

| HS Code: | 84137099.90 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Beijing,Shanghai |

2-Inch High Head Horizontal Slurry Pumps

Widely used for long distance transport pipelines, the SBH pumps are designed to produce high heads per stage at high pressures. And these slurry pumps can often satisfy applications with a single pump where others require multiple pumps in series. (For similar high pressure slurry pumps, please browse our website for local pumps and then for coal washing slurry pumps)

Applications

High head heavy duty metal lined slurry pumps

Processes

Integrated slurry pipeline systems

Size Range/Dimensions: Discharge Size 1'' to 6'' (25mm to 150mm)

Temperature range: 1-100°C

|

Pump Model |

S×D (inch) |

Allowable Max. Power (kw) |

Material | Clear Water Performance | Impeller | |||||||

| Capacity Q |

Head H(m) |

Speed n(r/min) |

Max.Eff. η% |

NPSH (m) |

No. of Vanes |

Vane Dia. (mm) |

Weight (kg) |

|||||

| Impeller | m3/h | l/s | ||||||||||

| SBH/25C | 1.5×1 | 30 |

Metal (A05) |

16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 | 318 |

| SBH/50D | 3×2 | 60 | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 | 750 | ||

| SBH/75E | 4×3 | 120 | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2-5 | 508 | 1250 | ||

| SBH/100F | 6×4 | 260 | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 720 | 2528 | ||

| SBH/100S | 6×4 | 560 | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 720 | 2880 | ||

| SBH/150S | 8×6 | 560 | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 711 | 3200 | ||

Materials: High Chrome Alloy, Corrosion Resistant Alloys

| Designation | Material Name | C | Mn | Si | Ni | Cr | Mo | Cu | P | V | S | Description | Hardness | |||

| A03 | Ni-Hard 1 | 3.0-3.6 | 0.3-0.7 | 0.3-0.5 | 3.3-4.8 | 1.5-2.6 | 0-0.4 | ... | ≤0.3 | ≤0.15 | ||||||

| A05 | Ultrachrome | 2.92 | 0.98 | 0.54 | 0.8 | 26~28 | ≤0.8 | ... | 0.062 | .. | 0.051 | 27% Cr Erosion Resistant White Iron | 58-62HRC | |||

| A06 | NI-Hard 4 | 3.2 | 0.2 | 1.5 | 4 | 8 | 0.5 | ... | 0.15 | ... | 0.12 | Martensitic White Iron | 62-67HRC | |||

| A07 | 15/3 Chrome/Moly Iron | 2.8-3.2 | 0.5-1.2 | 0.8-1.0 | ... | 15-17 | 2.8-3.2 | 0.8-1.2 | ... | ... | ... | Chromium/Molybdenum | ||||

| A33 | 1.55 | 1.2 | 1.29 | 1.89 | 36.7 | 1.92 | 1.31 | ... | ... | ... | Corrosion-resistant Chrome | |||||

| A49 | Ultrachrome | 1.57 | 0.71 | 1.36 | 2.01 | 28 | 1.96 | 1.32 | 0.038 | ... | 0.027 | 28% Cr, Low C, White Iron | ||||

|

|

||||||||||||||||

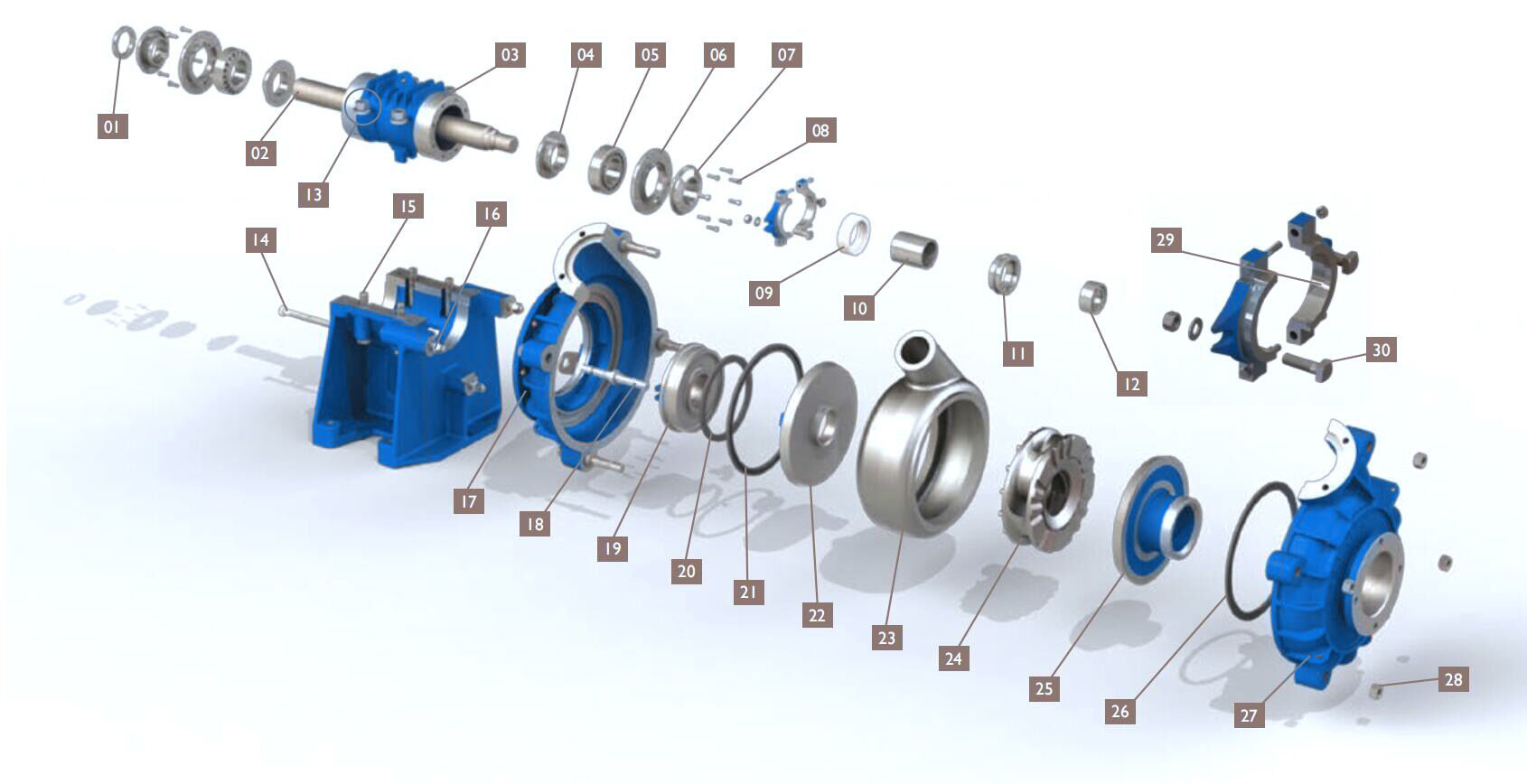

Key Features

1). Cast iron fully lined casings provide durability, strength and long service life

2). Heavy duty construction with throughbolt design provides ease of maintenance and results in less down time

3). Large diameter, slow turning, high efficiency impellers result in manimum wear life and lower operating costs

4) Full flush gland, low flow, and dry running centrifugal seals reduce flush water usage minimizing pump operating costs

Structure

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

Related Keywords