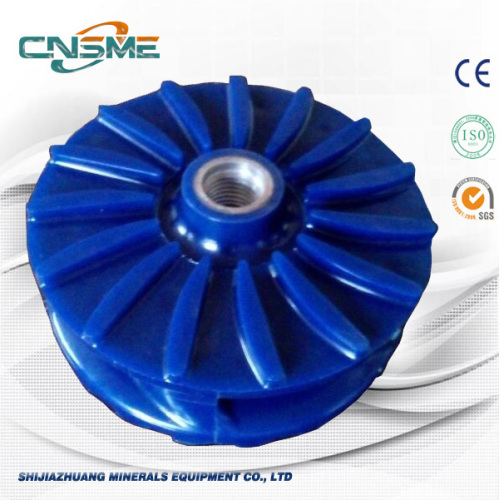

Polyurethane Impeller Of Slurry Pumps

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 Pcs per Month |

| Supply Ability: | 100 Pcs per Month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

Polyurethane Impeller Of Slurry Pumps

Introduction:

New polyurethane formulation to improve slurry-pumping capability.

Polyurethane product manufacturer SME is working closely with the mining industry to create abrasion-resistant polyurethane body liners and impellers for slurry pumps, which will extend the products' pump life.

The polyurethane formulation could also be used in pumps for chrome and for coal.

Related Products:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

PU characteristics:

1. Hardness: Shore 10 Shore D 64

2. Excellent in the fight against abrasion and chemical resistance, tensile strength

3. High flexibility, high load pressure, wear resistance, high strength, shock absorption and strong

4. Break, resistant to radiation, high load and amortization Depreciation

5. It is good adhesion to metal and with a wide range of hardness from Shore 10A-64D.

6. For superior cushioning, shock absorption cushioning pad, impact resistant than metal springs, so as not to damage the mold

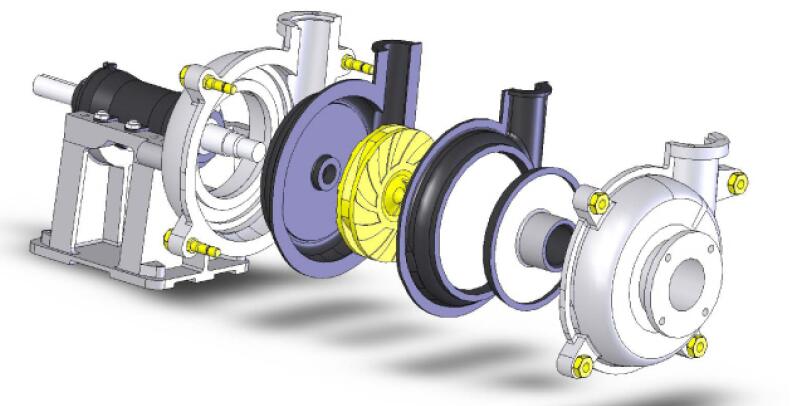

Polyurethane Pump Construction:

SME PU Parts Orders:

Related Keywords