Wear Resistant Rubber Liners

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 Pcs per Month |

| Supply Ability: | 100 Pcs per Month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

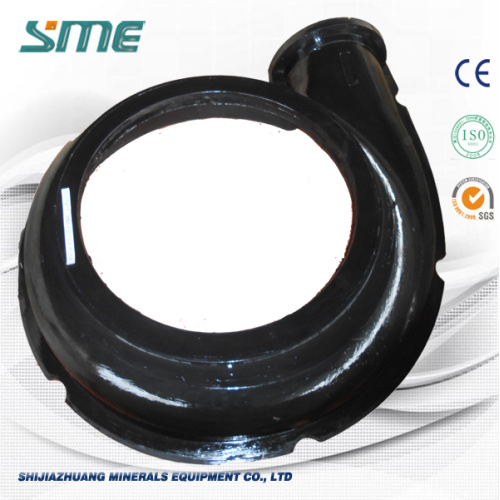

Wear Resistant Rubber Liners

Introduction:

A). We have been providing high quality slurry pumps, pump parts and services to overseas users for over 8 years, but we have 18 year's experience in this slurry pump business since the year 2010.

B). Our services include: sales, repairs, technical support, systems design, training, and consulting services.

C). SME (slurry pumps company) offers a variety of pump technologies for your fluid pumping process. Both our metal lined and rubber lined horizontal and vertical slurry pumps are equivalent to War-man original, and the spare parts are 100% interchangeable.

D). When sending inquiry or order please provide us original spare or wear part number.

1). Our Slurry line of pumps are designed for Mill discharge, process plant and tailings, high pressure pipelines, as well as other specialty uses.

2). Frame plate liner is the main part of the wetted parts of a rubber lined slurry pump. In a slurry pump the impeller and inside of the casing are always exposed to the slurry and have

to be protected accordingly against wear.

Material selection for impeller and casing is just as important as the pump selection itself.

3). The corrosion (and chemical attacks) of the wet parts in a Slurry Pump is a complex phenomenon both for metal and elastomer material. Natural rubber is by far the major elastomer in slurry pumping. Most cost effective for fine solids. Generally, depending on their sharpness and density, particle sizes of up to 5-8 mm can be pumped. Warning! Oversize scrap and sharp particles can destroy the wear parts, especially the impeller.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

Explosive View of Rubber Pump:

Orders of Rubber Components:

Related Keywords