solid welding wire used submerged arc welding

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China (Mainland) |

|---|

Product Description

Product Description

Specifications solid welding wire used submerged arc welding

Dia.0.8mm to 6.0mm

Submerged arc welding

Real copper plated,high quality

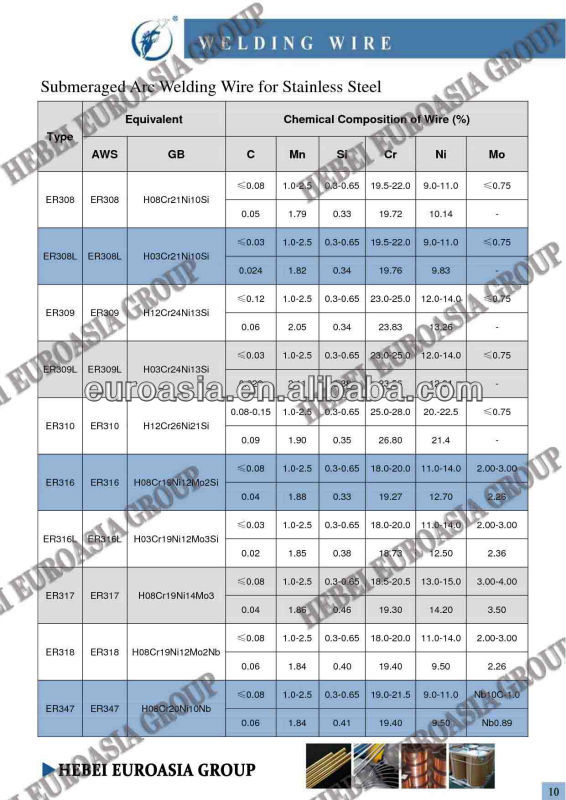

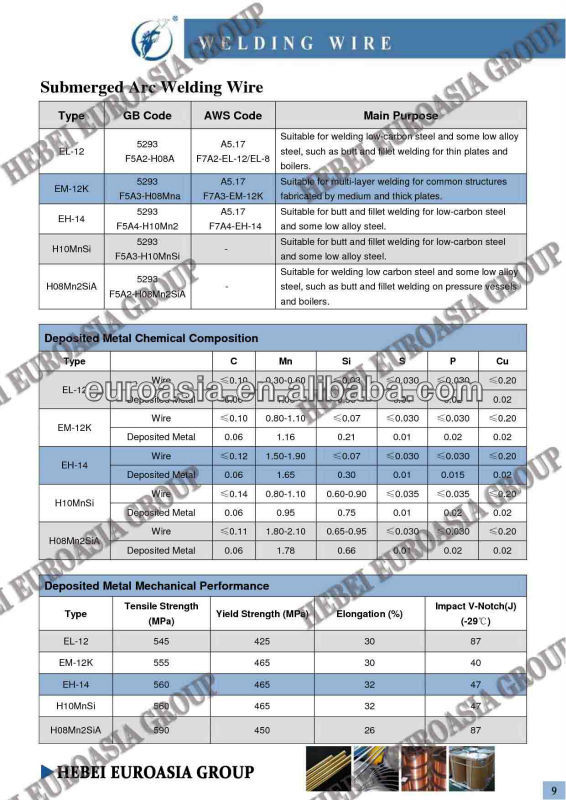

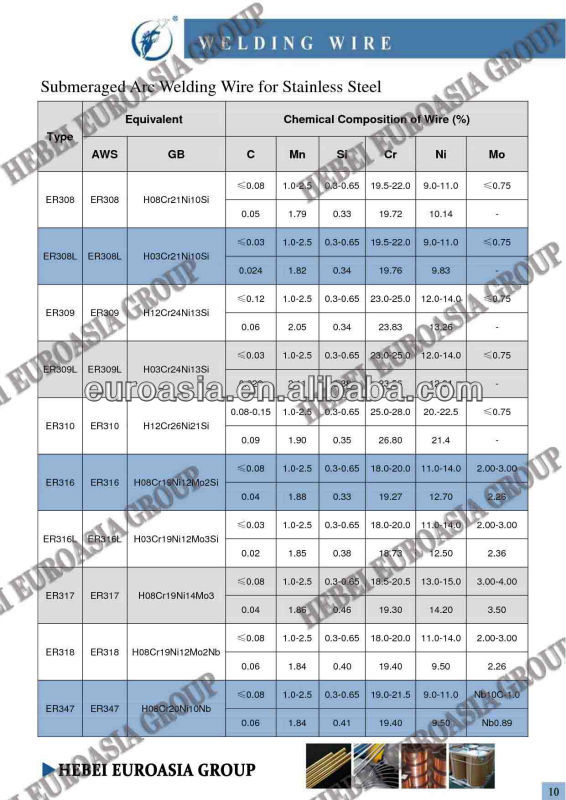

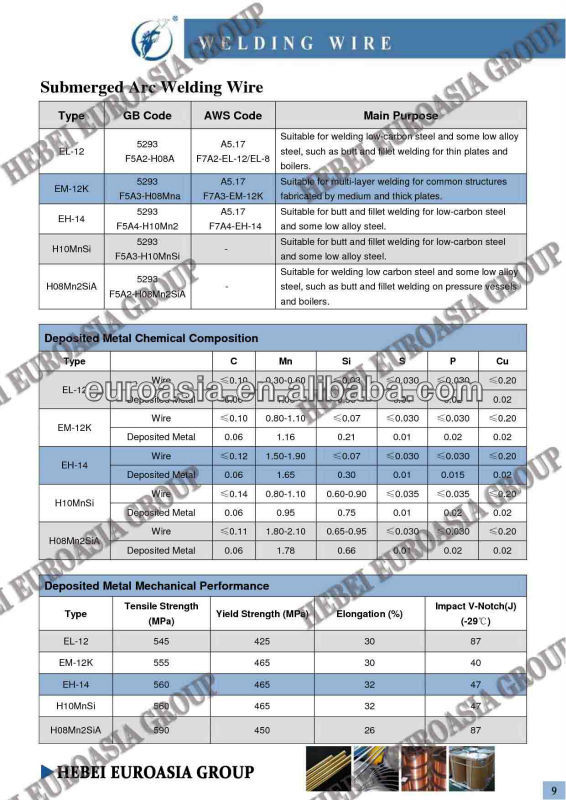

solid welding wire used submerged arc welding Introdution: Carbon steel submerged arc welding wires are used with corresponding flux and gotten excellent mechanical seam.They have a series of advantages,such as high effciency,stable welding quality, high depositing efficiency etc. The type of Submerged arc Welding Wire Solid welding wire, flux-cored welding wire Carbon steel welding wire,alloyed steel welding wire, AWS EL-12,EM-12K,EH14, Carbon Steel, low alloyed steel SAW wire

Application: The series of welding wires are used to welding important low carbon steel and low allow steel structure, such as boils,nuclear stations,chemical containers,ships,pressure containers etc.They have good anti-pore performance, the welding slag is easy to flake, high welding efficiency and tenacity. Deposited metal Chemistry Composition:

Deposited metal Machine Functions:

Diameter and Current:

Main Specification & Type

Packing Style

Packing Style

Dia.0.8mm to 6.0mm

Submerged arc welding

Real copper plated,high quality

solid welding wire used submerged arc welding Introdution: Carbon steel submerged arc welding wires are used with corresponding flux and gotten excellent mechanical seam.They have a series of advantages,such as high effciency,stable welding quality, high depositing efficiency etc. The type of Submerged arc Welding Wire Solid welding wire, flux-cored welding wire Carbon steel welding wire,alloyed steel welding wire, AWS EL-12,EM-12K,EH14, Carbon Steel, low alloyed steel SAW wire

Typical Analysis of undiluted Weld Metal % | |||||||||

Products | Welding Process | Chemical Composition | Matched Fluxes | ||||||

C | Mn | Si | Cr | Ni | S | P | |||

H08A/EL8/W11 | SAW welding | ≤0.10 | 0.30-0.55 | ≤0.03 | ≤0.20 | ≤0.30 | ≤0.030 | ≤0.030 | HJ430,HJ431,HJ433,HJ350,HJ301,UV420TT,UV421TT,UV418TT,VU306,UV400 |

H08E/EL8/W11 | SAW welding | ≤0.10 | 0.30-0.55 | ≤0.03 | ≤0.20 | ≤0.30 | ≤0.025 | ≤0.025 | |

H08MnA/EM12/W11/S2 | SAW welding | ≤0.10 | 0.80-1.10 | ≤0.07 | ≤0.20 | ≤0.30 | ≤0.030 | ≤0.030 | |

Deposited Metal Mechanical Performance | ||||

Products | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation ( % ) | Impact V- Notch 0oC ( J ) |

H08A/EL8/W11 | 410-550 | ≥330 | ≥22 | ≥27 |

H08E/EL8/W11 | 410-550 | ≥330 | ≥22 | ≥27 |

H08MnA/EM12/W11/S2 | 410-550 | ≥330 | ≥22 | ≥27 |

| TYPE | C | Mn | Si | P | S | Cu |

| H08MnA | 0.07 | 0.94 | 0.24 | 0.011 | 0.025 | 0.01 |

| TYPE | Tensile Strength Mpa | Yield Point % | Elongation % | AKV-20 J |

| H08MnA | 521 | 425 | 32 | 85 |

| Diameter (mm) | 2.5mm | 3.2mm | 4.0mm | 5.0mm |

| Currents (A) | 350-450 | 425-525 | 475-575 | 550-650 |

Packing Style

Packing Style

Related Keywords

Related Keywords