JIS W41 alloyed steel welding wire for submerged welding

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Specifications JIS W41 alloyed steel welding wire for submerged welding

Diameter 0.8,1.2,2.5,3.0,3.2mm

Copper plated solid core

cheap price

JIS W41 alloyed steel welding wire for submerged welding coating copper welding wire EM13K Introdution: Carbon steel submerged arc welding wires are used with corresponding flux and gotten excellent mechanical seam.They have a series of advantages,such as high effciency,stable welding quality, high depositing efficiency etc. Surface Finishing: Coppered,copper plated,passivating, anti-rust oil, Main Series: GB G08A,G08E,H08MnA,H10Mn2,H10MnSi,H08MnMoA,H08Mn2MoA,H10Mn2NiMoA,H08CrMoA,h13CrMoA AWS EL8,EL12,EM12,EH14,EM13K,EB2,F9P2-EG-G JIS W11,W41 EN756 S1,S2,S3,S3Si, Carbon Steel, low alloyed steel SAW wire

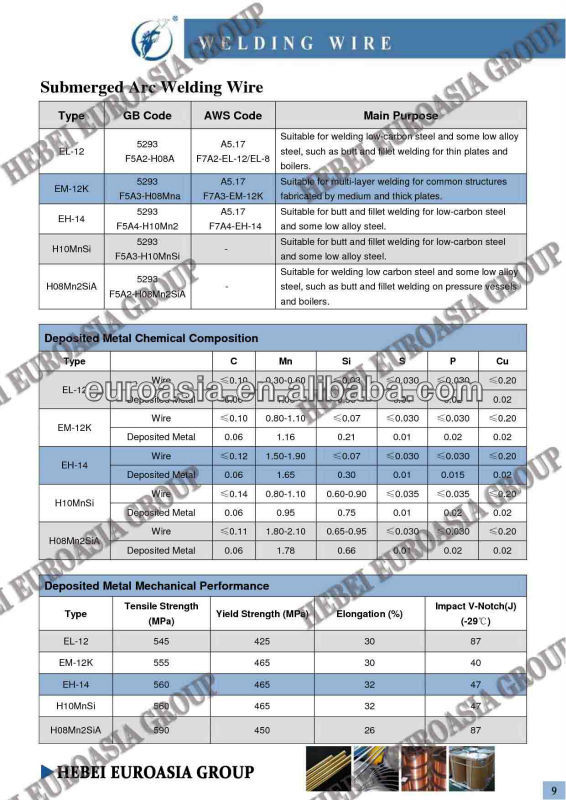

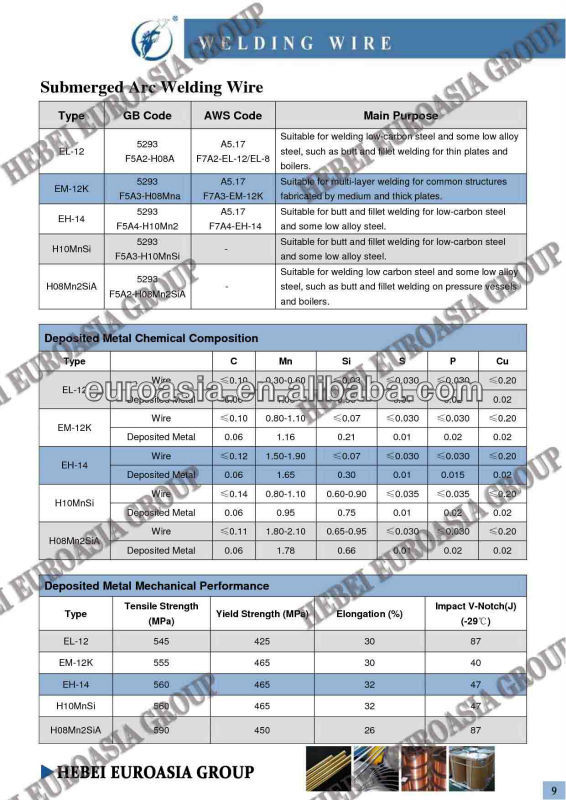

Application: The series of welding wires are used to welding important low carbon steel and low allow steel structure, such as boils,nuclear stations,chemical containers,ships,pressure containers etc.They have good anti-pore performance, the welding slag is easy to flake, high welding efficiency and tenacity. Deposited metal Chemistry Composition:

Deposited metal Machine Functions:

Diameter and Current:

Application: The series of welding wires are used to welding important low carbon steel and low allow steel structure, such as boils,nuclear stations,chemical containers,ships,pressure containers etc.They have good anti-pore performance, the welding slag is easy to flake, high welding efficiency and tenacity. Deposited metal Chemistry Composition:

Deposited metal Machine Functions:

Diameter and Current:

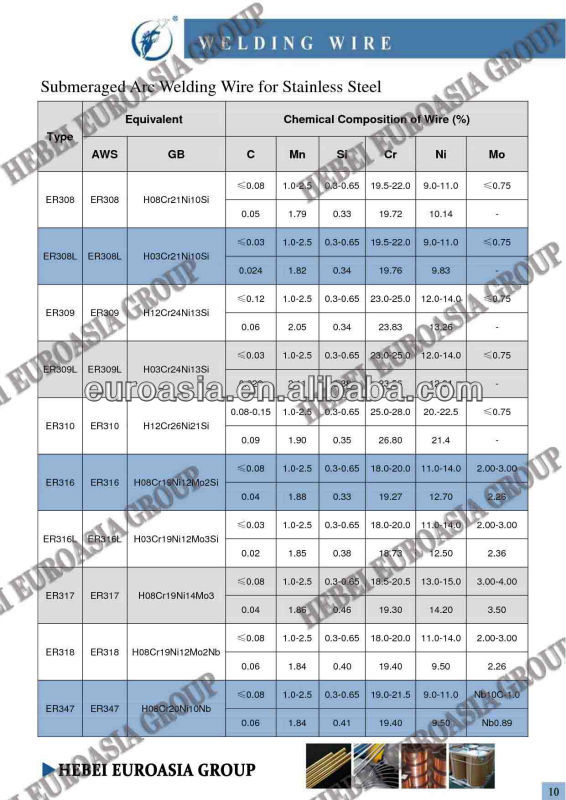

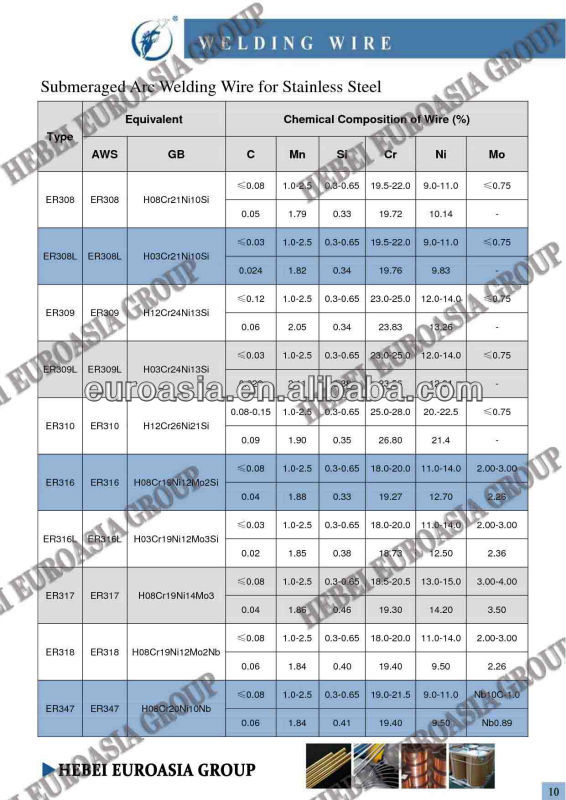

Main Specification & Type

Packing Style

Packing Style

PLS CONTACT US FOR INQUIRY,CATALOGUE,SAMPLES OR DISCUSS COOPERATION. AS A PROFESSIONAL SUPPLIER OF WELDING WIRE,WE CAN SUPPY YOU THE QUALITY GOODS AN CHEAPER PRICE. OUR MAIN PRODUCTS:FLUX CORE WELDING WIRE,CO2 WELDING WIRES, SUBMERGD ARC WELDING WIRE, ETC.

PLS CONTACT US FOR INQUIRY,CATALOGUE,SAMPLES OR DISCUSS COOPERATION. AS A PROFESSIONAL SUPPLIER OF WELDING WIRE,WE CAN SUPPY YOU THE QUALITY GOODS AN CHEAPER PRICE. OUR MAIN PRODUCTS:FLUX CORE WELDING WIRE,CO2 WELDING WIRES, SUBMERGD ARC WELDING WIRE, ETC.

Diameter 0.8,1.2,2.5,3.0,3.2mm

Copper plated solid core

cheap price

JIS W41 alloyed steel welding wire for submerged welding coating copper welding wire EM13K Introdution: Carbon steel submerged arc welding wires are used with corresponding flux and gotten excellent mechanical seam.They have a series of advantages,such as high effciency,stable welding quality, high depositing efficiency etc. Surface Finishing: Coppered,copper plated,passivating, anti-rust oil, Main Series: GB G08A,G08E,H08MnA,H10Mn2,H10MnSi,H08MnMoA,H08Mn2MoA,H10Mn2NiMoA,H08CrMoA,h13CrMoA AWS EL8,EL12,EM12,EH14,EM13K,EB2,F9P2-EG-G JIS W11,W41 EN756 S1,S2,S3,S3Si, Carbon Steel, low alloyed steel SAW wire

Typical Analysis of undiluted Weld Metal % | |||||||||

Products | Welding Process | Chemical Composition | Matched Fluxes | ||||||

C | Mn | Si | Cr | Ni | S | P | |||

H08A/EL8/W11 | SAW welding | ≤0.10 | 0.30-0.55 | ≤0.03 | ≤0.20 | ≤0.30 | ≤0.030 | ≤0.030 | HJ430,HJ431,HJ433,HJ350,HJ301,UV420TT,UV421TT,UV418TT,VU306,UV400 |

H08E/EL8/W11 | SAW welding | ≤0.10 | 0.30-0.55 | ≤0.03 | ≤0.20 | ≤0.30 | ≤0.025 | ≤0.025 | |

H08MnA/EM12/W11/S2 | SAW welding | ≤0.10 | 0.80-1.10 | ≤0.07 | ≤0.20 | ≤0.30 | ≤0.030 | ≤0.030 | |

Deposited Metal Mechanical Performance | ||||

Products | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation ( % ) | Impact V- Notch 0oC ( J ) |

H08A/EL8/W11 | 410-550 | ≥330 | ≥22 | ≥27 |

H08E/EL8/W11 | 410-550 | ≥330 | ≥22 | ≥27 |

H08MnA/EM12/W11/S2 | 410-550 | ≥330 | ≥22 | ≥27 |

| TYPE | C | Mn | Si | P | S | Cu |

| H08MnA | 0.07 | 0.94 | 0.24 | 0.011 | 0.025 | 0.01 |

| TYPE | Tensile Strength Mpa | Yield Point % | Elongation % | AKV-20 J |

| H08MnA | 521 | 425 | 32 | 85 |

| Diameter (mm) | 2.5mm | 3.2mm | 4.0mm | 5.0mm |

| Currents (A) | 350-450 | 425-525 | 475-575 | 550-650 |

| TYPE | C | Mn | Si | P | S | Cu |

| H08MnA | 0.07 | 0.94 | 0.24 | 0.011 | 0.025 | 0.01 |

| TYPE | Tensile Strength Mpa | Yield Point % | Elongation % | AKV-20 J |

| H08MnA | 521 | 425 | 32 | 85 |

| Diameter (mm) | 2.5mm | 3.2mm | 4.0mm | 5.0mm |

| Currents (A) | 350-450 | 425-525 | 475-575 | 550-650 |

Packing Style

Packing Style

PLS CONTACT US FOR INQUIRY,CATALOGUE,SAMPLES OR DISCUSS COOPERATION. AS A PROFESSIONAL SUPPLIER OF WELDING WIRE,WE CAN SUPPY YOU THE QUALITY GOODS AN CHEAPER PRICE. OUR MAIN PRODUCTS:FLUX CORE WELDING WIRE,CO2 WELDING WIRES, SUBMERGD ARC WELDING WIRE, ETC.

PLS CONTACT US FOR INQUIRY,CATALOGUE,SAMPLES OR DISCUSS COOPERATION. AS A PROFESSIONAL SUPPLIER OF WELDING WIRE,WE CAN SUPPY YOU THE QUALITY GOODS AN CHEAPER PRICE. OUR MAIN PRODUCTS:FLUX CORE WELDING WIRE,CO2 WELDING WIRES, SUBMERGD ARC WELDING WIRE, ETC. Related Keywords

Related Keywords