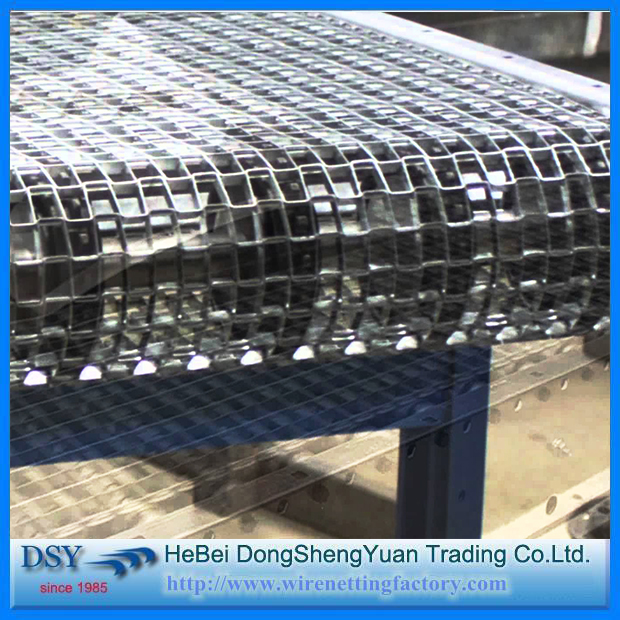

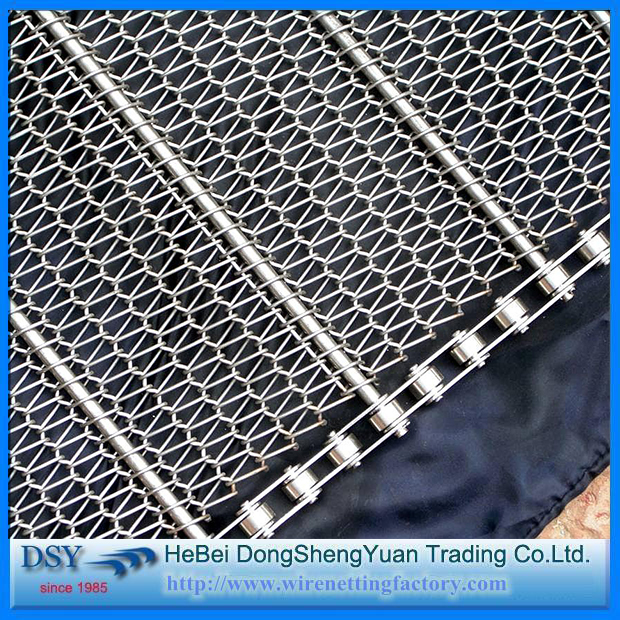

Belt Conveyer/roller conveyer/convery equipment

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Product Description oil resistant rubber conveyor belts used in mining, fan belt Oil resistant conveyor belt carries parts and components coated with machin oil heavy oil treated coal in cookong plants and ele The best compounded of oil resistant synthetic rubber has good resistance to damaging effects encountered when conveying oil contaminated or tread materials Oil conveyor belt can divided into two types according to cover properies anti-abrasive type and ordinary type

Oil resistant conveyor belt

Oil resistant conveyor belt

1.Types:EP80-EP630

2.Width:400MM-2400MM

3.Thickness:4-50mm

4.Tensile Strength:6MPA-25MPA oil resistant rubber conveyor belts used in mining, fan belt Oil resistant conveyor belt carries parts and components coated with machin oil heavy oil treated coal in cookong plants and ele The best compounded of oil resistant synthetic rubber has good resistance to damaging effects encountered when conveying oil contaminated or tread materials Oil conveyor belt can divided into two types according to cover properies anti-abrasive type and ordinary type

oil resistant rubber conveyor belts used in mining, fan belt Oil resistant conveyor belt carries parts and components coated with machin oil heavy oil treated coal in cookong plants and ele The best compounded of oil resistant synthetic rubber has good resistance to damaging effects encountered when conveying oil contaminated or tread materials Oil conveyor belt can divided into two types according to cover properies anti-abrasive type and ordinary type

Packaging & Shipping Shipping:within 20 days after recieved prepayment. Packaging: export standard

Packaging & Shipping Shipping:within 20 days after recieved prepayment. Packaging: export standard

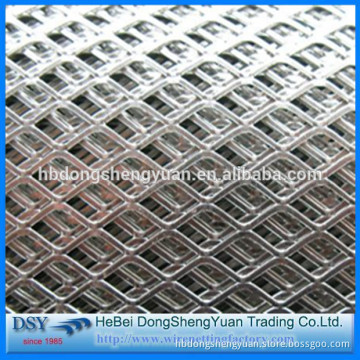

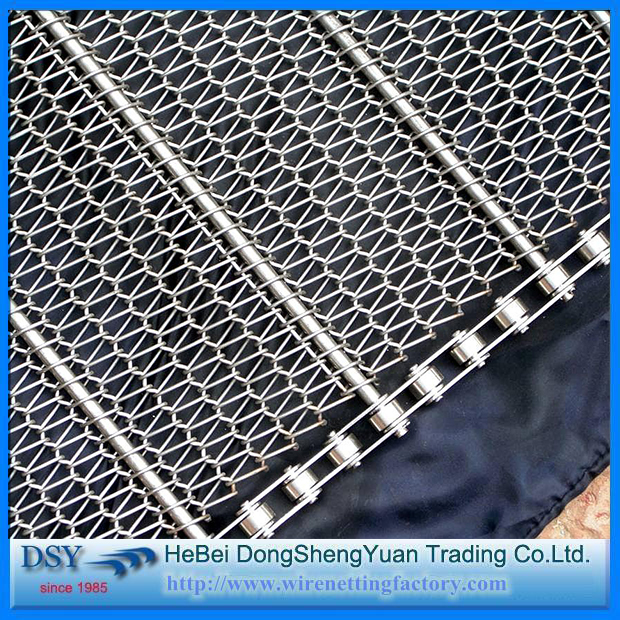

Company Information Hebei Dongshengyuan Wire Mesh Factory is a full service manufacturer of wire, woven wire mesh and wire processed products. Started since 1985, Dongshengyuan can supply good quality stainless steel wire mesh, chain link fence, vibrating screen wire mesh, fiberglass mesh, U type wire, PVC coated wire, wire mesh fences, expanded metal, perforated metal and various wire products. Hebeidongshengyuan hopes to establish new business with new clients and keep stable cooperation with old clients in the future.we would be pleased to provide hige qulity products and effective services for you on the basis of frank cooperation and mutual benefit.

Company Information Hebei Dongshengyuan Wire Mesh Factory is a full service manufacturer of wire, woven wire mesh and wire processed products. Started since 1985, Dongshengyuan can supply good quality stainless steel wire mesh, chain link fence, vibrating screen wire mesh, fiberglass mesh, U type wire, PVC coated wire, wire mesh fences, expanded metal, perforated metal and various wire products. Hebeidongshengyuan hopes to establish new business with new clients and keep stable cooperation with old clients in the future.we would be pleased to provide hige qulity products and effective services for you on the basis of frank cooperation and mutual benefit.

| The covering layer of the oil proof conveyer belt uses the butadiene-acrylonitrile rubber with high content of acrylonitdta, using cotton canvas, nylon canvas or EP canvas as the strong layer, which is suitable for transferring oily matedals or some kind of oily condition(excluding fuel and solvent oil). It has the advantage of Iow changing rate of volume, high intensity conservation rate, wide range of use. |

| The physics and mechanical properties of the oily conveyer belt covedng layer rubber are as mentioned in the following table: |

| Type | Break the intensity /Mpa | Break extension rate /% | Wearing and tearing /mm3 |

| LO | ≥14.0 | ≥350 | ≤200 |

| DO | ≥16.0 | ≥350 | ≤160 |

| Notes: LO--Oily conveyer belt under the general condition; DO--Conveyer belt under the shock resistant and oily condition. | |||

| Oil proof performance of the oil proof conveyer belt covering layer is as mentioned in the following table: |

Oil resistant conveyor belt

Oil resistant conveyor belt 1.Types:EP80-EP630

2.Width:400MM-2400MM

3.Thickness:4-50mm

4.Tensile Strength:6MPA-25MPA

oil resistant rubber conveyor belts used in mining, fan belt Oil resistant conveyor belt carries parts and components coated with machin oil heavy oil treated coal in cookong plants and ele The best compounded of oil resistant synthetic rubber has good resistance to damaging effects encountered when conveying oil contaminated or tread materials Oil conveyor belt can divided into two types according to cover properies anti-abrasive type and ordinary type

oil resistant rubber conveyor belts used in mining, fan belt Oil resistant conveyor belt carries parts and components coated with machin oil heavy oil treated coal in cookong plants and ele The best compounded of oil resistant synthetic rubber has good resistance to damaging effects encountered when conveying oil contaminated or tread materials Oil conveyor belt can divided into two types according to cover properies anti-abrasive type and ordinary type

| The covering layer of the oil proof conveyer belt uses the butadiene-acrylonitrile rubber with high content of acrylonitdta, using cotton canvas, nylon canvas or EP canvas as the strong layer, which is suitable for transferring oily matedals or some kind of oily condition(excluding fuel and solvent oil). It has the advantage of Iow changing rate of volume, high intensity conservation rate, wide range of use. |

| The physics and mechanical properties of the oily conveyer belt covedng layer rubber are as mentioned in the following table: |

| Type | Break the intensity /Mpa | Breakxtension rate /% | Wearing and tearing /mm3 |

| LO | ≥14.0 | ≥350 | ≤200 |

| DO | ≥16.0 | ≥350 | ≤160 |

| Notes: LO--Oily conveyer belt under the general condition; DO--Conveyer belt under the shock resistant and oily condition. | |||

| Oil proof performance of the oil proof conveyer belt covering layer is as mentioned in the following table: |

| Serial number | Experimental condition in soaking the liquidm | Rate of change of the volume /%≤ | |||

| Oil number in GB/T1690 | Soaking temperature /°C | Soaking time /h | LO | DO | |

| 1 | Oil No.2 | 70±2 | 70- | +20 | -5 |

| 2 | Oil No.3 | 70±2 | 70- | +50 | +5 |

| 3 | Oil No.3 | 100±2 | 22±0.25 | +50 | +5 |

Packaging & Shipping Shipping:within 20 days after recieved prepayment. Packaging: export standard

Packaging & Shipping Shipping:within 20 days after recieved prepayment. Packaging: export standard

Company Information Hebei Dongshengyuan Wire Mesh Factory is a full service manufacturer of wire, woven wire mesh and wire processed products. Started since 1985, Dongshengyuan can supply good quality stainless steel wire mesh, chain link fence, vibrating screen wire mesh, fiberglass mesh, U type wire, PVC coated wire, wire mesh fences, expanded metal, perforated metal and various wire products. Hebeidongshengyuan hopes to establish new business with new clients and keep stable cooperation with old clients in the future.we would be pleased to provide hige qulity products and effective services for you on the basis of frank cooperation and mutual benefit.

Company Information Hebei Dongshengyuan Wire Mesh Factory is a full service manufacturer of wire, woven wire mesh and wire processed products. Started since 1985, Dongshengyuan can supply good quality stainless steel wire mesh, chain link fence, vibrating screen wire mesh, fiberglass mesh, U type wire, PVC coated wire, wire mesh fences, expanded metal, perforated metal and various wire products. Hebeidongshengyuan hopes to establish new business with new clients and keep stable cooperation with old clients in the future.we would be pleased to provide hige qulity products and effective services for you on the basis of frank cooperation and mutual benefit.

Related Keywords

Related Keywords

You May Also Like

You May Also Like