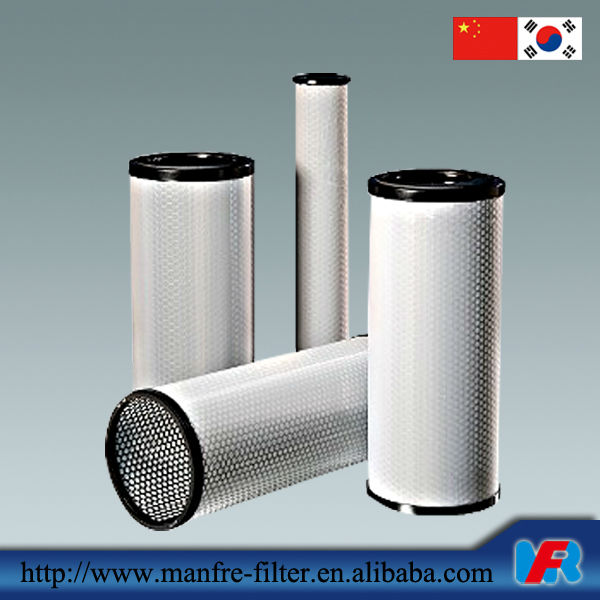

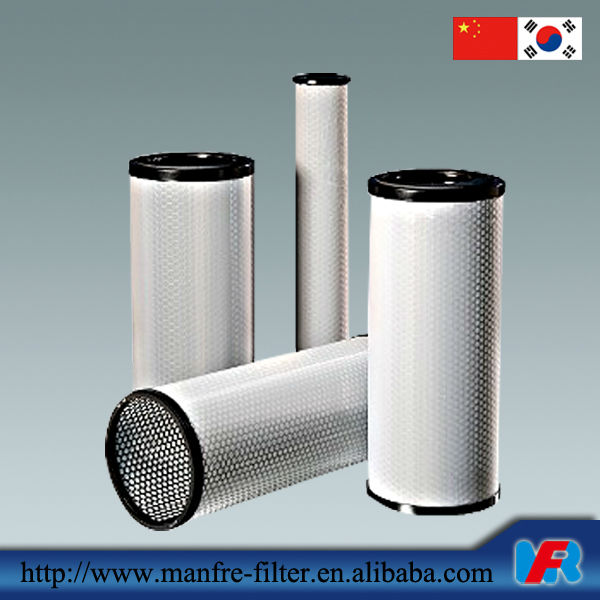

coalescing oil filter element by manufacturer

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Specifications 1.General purpose sealing

2.Advanced Korea technology

3.Strength and durability

4.Perfect after-service system

Descriptions Coalescence oil filter is clogged and should be replaced when the differential pressure rises to 0.15Mpa. Fluid from the coalescence separator inlet flow to a tray, and then internal shunt to a filter, filtered, demulsification, water molecules grew, coalescence process, impurities trapped in a filter element, the coalescent drops settlement in the settling tank, the oil from the outside into the secondary filter, bringing together two trays from the coalescence separator outlet. Two filter material is hydrophobic, oil can pass free water were blocked outside the filter into the settling tank and discharged through the discharge of sewage valve. The oil-water separator filter is designed for oil - water liquid separation ,containing two filters ,namely: poly filter and separation filter. Technical Specification Mterial :Micron glass fibre Filtration Rating:0.01~10μm Maximum Pressure Drop: 0.6Mpa Operating Temperature: -200~330oC Features a. Multi-layers complex structure filter paper, high filter precision. b. Large dirt holding capacity, long service time c. High flow density, reduced fine filter size. d. Fiber glass layer, good coalescing effect. e. The filter structure and material meet standard requirements. f. Many specifications, can meet requirement for different filter precision. Filter Test Standard · ISO2941Collapse&Burst Resistant · ISO 2942 Fabrication&Integrity Test · ISO 2943 Material Compatibility with Fluids · ISO 3724 Flow Fatigue characteristics · ISO 3968 Pressure DropVs.Flow Rate · ISO 16889 Muti-pass Performance Testing

2.Advanced Korea technology

3.Strength and durability

4.Perfect after-service system

Descriptions Coalescence oil filter is clogged and should be replaced when the differential pressure rises to 0.15Mpa. Fluid from the coalescence separator inlet flow to a tray, and then internal shunt to a filter, filtered, demulsification, water molecules grew, coalescence process, impurities trapped in a filter element, the coalescent drops settlement in the settling tank, the oil from the outside into the secondary filter, bringing together two trays from the coalescence separator outlet. Two filter material is hydrophobic, oil can pass free water were blocked outside the filter into the settling tank and discharged through the discharge of sewage valve. The oil-water separator filter is designed for oil - water liquid separation ,containing two filters ,namely: poly filter and separation filter. Technical Specification Mterial :Micron glass fibre Filtration Rating:0.01~10μm Maximum Pressure Drop: 0.6Mpa Operating Temperature: -200~330oC Features a. Multi-layers complex structure filter paper, high filter precision. b. Large dirt holding capacity, long service time c. High flow density, reduced fine filter size. d. Fiber glass layer, good coalescing effect. e. The filter structure and material meet standard requirements. f. Many specifications, can meet requirement for different filter precision. Filter Test Standard · ISO2941Collapse&Burst Resistant · ISO 2942 Fabrication&Integrity Test · ISO 2943 Material Compatibility with Fluids · ISO 3724 Flow Fatigue characteristics · ISO 3968 Pressure DropVs.Flow Rate · ISO 16889 Muti-pass Performance Testing

Related Keywords

Related Keywords