2023 Best Selling 100-ton/24-hour Maize Flour Machine

-

$198000.001-1 set

-

$168000.002-2 set

-

$138000.00≥3 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

- Port:

- TIANJIN CHINA OR CUSTOMIZED

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,Western Union,T/T,MoneyGram,Cash |

| Port: | TIANJIN CHINA OR CUSTOMIZED |

Product Description

Product Description

Product Overview

Fully automatic 100T per day maize flour machine

This 100T automatic maize flour machine is a complete line including cleaning to degerminating to milling to automatic packing and touch screen control systems.

You can get the super white pure corn grits with different size from this automatic 100 ton/24h maize flour machine. Our machine can make different products from maize grain, like maize fine flour, maize grits and maize bran, maize germ, you can get different products to meet various need from the market.

Product Details

1.parameter

Model | HDF-100 Maize flour machine | ||||||

Production Capacity | 100T per day | ||||||

Main machines and processing techniques | High efficiency vibration sifter, Destoner, Damper, Peeling machine, Embryo separator, Polisher, Grading machine, Roller mill | ||||||

Products and extraction rate (%) | Maize flour: 40-50%;Maize grits: 35-40% Maize bran, coarse fodder:10-12% | ||||||

Products quality index | Sand content: ≤0.02% ;Fat content: ≤2.5% | ||||||

Power required (kW) | Around 160 | ||||||

Size of workshop (L×W×H) | 37*18.5*11.5M | ||||||

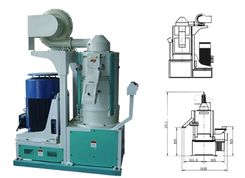

2.Main machine introduction

Vibrating Sifter

The maize flows into the first sieve surface through feeding entrance. Inside this surface, large impurity on the upper sieve is discharged to the hopper. The maize through the first sieve surface to the second sieve surface for continual filter. The small impurity is discharged on the soleplate straightly, the clean stock on the upper sieve surface come to the discharging hopper through the suction road.

Destoner

Destoner is applied for efficient separation of stones and pebbles, glass, and other high-density matter from the stram of grain. The destoner is also used to process rye, rice, and soybeans. High separating efficiency - excellent grain cleaning

Moisture damper

The damper can add water to moisten the raw maize. Double layer damper, stainless steel one without rusty and working life is longer than the steel one. Two layers for moisturing much more efficiency.

Degerminator

Maize degerminator is applicable for

taking the germ and bran out of the

maize, at the same time polishing the maize/maize gritz,get pure white /

yellow maize meal,maize grits,maize

samp, and is characteristic of high

volume of production, compact

structure and convenient maintenance, thus making it an ideal equipment for

maize processing in the modern age.

Pneumatic roller mill

1)The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls. This makes residue-free cleaning possible.

2) A pulse generator automatically adjust the feed material at the entrance door

Double section

Double sifter adopts the none-vertical axis and self-balance drive mechanism,It is manly used as the checker sifter for special flour to check the flour before packing.and can make a supplementary cleaning of powder material after being grinded

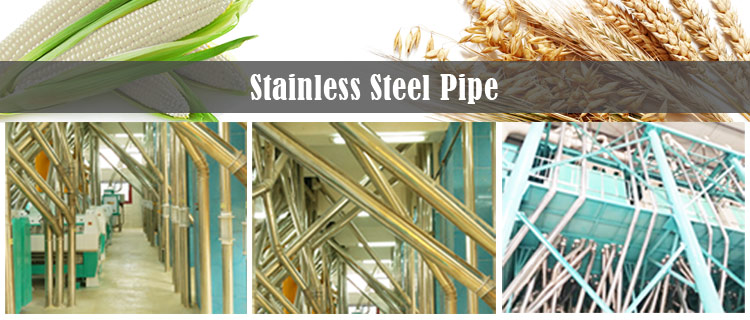

Stainless Steel Pipe in the maize flour machine section the pipe is stainless steel. It is much more durable

Touch Screen Control is smart touch screen control, which is advance operation, and easily operation. and with a working history checking system. With fault alarm system.

Automatic packing section for maize flour machine.

It can pack 5kg,10kg,20kg,50kg,100kg,200kg,etc woven bags.

One worker can operate for filling, weighing, and sealing.

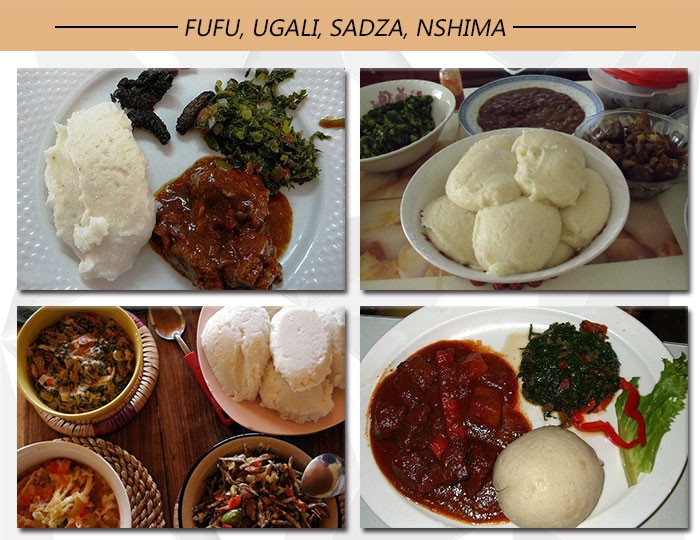

3.Finished product

The final product of Hongdefa 100t/24h maize flour machine

The final product of Hongdefa 100t/24h maize flour machine

Our maize milling machine can produce different specification super fine maize flour, roller meal,maize grits, maize samp, etc. The final product can be adjust according to clients’ local market situation and requirements.

The maize fine flour can be used for making stable food like Ugali, fufu, Sadza,Nshima etc. maize grits for making snacks, maize bran can make feedstuff for animal use, and maize germ can make oil.

4.Branch Office

We have three overseas offices: Ethiopia office, Zambia office and Uganda office.Engineers have been stationed overseas for a long time.so it is very convenient to provide Pre-sales consultation and after-sales service

5.Succese Project

6.Logistics

We have long-term cooperation with many logistics companies, which means that we will choose the most suitable logistics company for your country to transport your goods according to your actual situation, and do our best to ensure your goods transporting for your hand

About us

certificate

This is our Hongdefa Certificate. We have Drum Sifter Patent,Degerminator Patent and

Gravity Table Patent. And our maize mill and wheat flour mill machines have passed ISO SGS BV CE certifications.

Gravity Table Patent. And our maize mill and wheat flour mill machines have passed ISO SGS BV CE certifications.

Customer Photos

Our customers are all over the world market, such as Zambia, Uganda, Ethiopia, Angola, South Africa, Malawi, Kenya, Nigeria, Congo, Egypt, Pakistan, India, Cameroon, Thailand, Argentina, Peru, etc.

Hongdefa Team

Hongdefa have 20 super sales representatives, 25 professional high-level engineers, 68 engineers.

This is a picture of some of our engineers installing the equipment:

1.Q:What mill does Hongdefa machine use?

A: Pneumatic Roller Mills

The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls. This makes residue-free cleaning possible.

And the pulse generator can automatically adjust the feed at the entrance, saving time and effort

2.Q:What is the function of the Degerminator?

A: maize degerminator is applicable for taking the germ and bran out of the maize,at the same time

polishing the maize/maize gritz,get pure white /yellow maize meal,maize grits,maize samp, and is characteristic of

high volume of production, compact structure and convenient maintenance, thus making it an ideal equipment for

maize processing in the modern age.

3.Q:How to put 100T per day maize flour machine plant into my existing workshop?

A:We have the most professional engineer team to design according to your actual plant size the most suitable line and meet clients' demand

4.Q:Can this equipment produce both flour and grits at the same time?

A:We can design the production line according to the final product required by the customer, and can produce flour and grits at the same time through the technological process of different configurations.

5.Q:What material is the pipe?

A:Our cyclone and powder piping is made of stainless steel to extend the life of the equipment

6.Q:What are the advantages of Touch screen panel

A: The touch screen control model is more advanced, it can be set to manual button setting and automatic PLC setting, the operation is simple and display is more clearer.

clients can see the working of the each machine in maize mill direclty from the screen.

Related Keywords

Related Keywords

You May Also Like

You May Also Like